Planetary transmission mechanism with variable transmission chain and transmission mode of planetary reducer

A planetary transmission and transmission chain technology, applied in transmissions, gear transmissions, transmission parts, etc., can solve problems such as large transmission ratio of the reducer, high speed of the reducer, and damage to parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

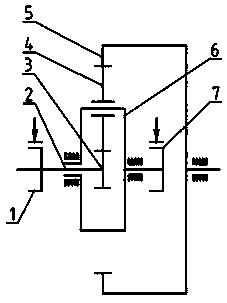

Embodiment 1

[0023] Embodiment 1: A planetary transmission mechanism with a variable transmission chain, which includes an input shaft 2, a sun gear, a planetary gear, a planetary carrier, and a ring gear. The planetary gear is arranged on the planetary carrier through a bearing, and the sun gear The ring connection also includes the input end brake 1, the final planetary carrier brake 7, the input end brake 1 brakes the input shaft 2, the final planetary carrier brake 7 brakes the last stage planetary carrier 6, the input end brake 1 and the input shaft 2 connection, the input shaft 2 is connected with the first-stage sun gear 3, the first-stage sun gear 3 meshes with the first-stage planetary gear 4, the first-stage planetary gear 4 meshes with the first-stage ring gear 5, and the first-stage planetary gear 4 meshes with the last-stage planet carrier 6 connection, the final planetary carrier brake 7 is connected with the final planetary carrier 6.

[0024] A planetary reducer transmissio...

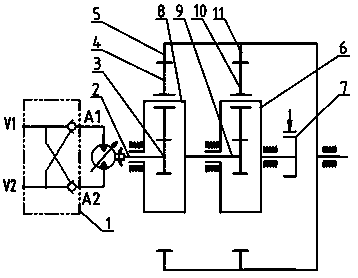

Embodiment 2

[0027] A planetary transmission mechanism with a variable transmission chain, which includes an input shaft 2, a sun gear, a planetary gear, a planet carrier, and a ring gear. Including input end brake 1, final stage planet carrier brake 7, input end brake 1 brakes input shaft 2, final stage planet carrier brake 7 brakes final stage planet carrier 6, said input end brake 1 is connected with input shaft 2, input The shaft 2 is connected with the primary sun gear 3, the primary sun gear 3 meshes with the primary planetary gear 4, the primary planetary gear 4 meshes with the primary ring gear 5, and the primary planetary gear 4 is connected with the primary planet carrier 8. The first-stage planetary carrier brake 7 is connected to the last-stage planetary carrier 6, the first-stage planetary carrier 8 is connected to the second-stage sun gear 9, the second-stage sun gear 9 is meshed with the second-stage planetary gear 10, and the second-stage planetary gear 10 is connected to th...

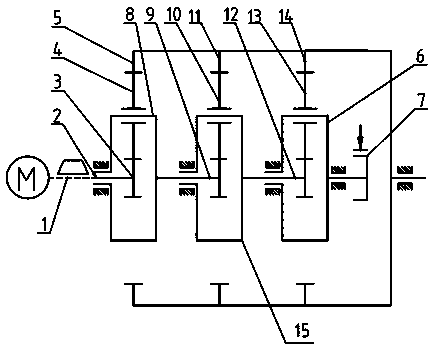

Embodiment 3

[0030] A planetary transmission mechanism with a variable transmission chain, which includes an input shaft 2, a sun gear, a planetary gear, a planet carrier, and a ring gear. Including input end brake 1, final stage planet carrier brake 7, input end brake 1 brakes input shaft 2, final stage planet carrier brake 7 brakes final stage planet carrier 6, said input end brake 1 is connected with input shaft 2, input Shaft 2 is connected with primary sun gear 3, primary sun gear 3 meshes with primary planetary gear 4, primary planetary gear 4 meshes with primary ring gear 5, primary planetary gear 4 is connected with primary planetary carrier 8, and primary planetary gear 4 is connected with primary planet carrier 8. The primary planetary carrier 8 is connected to the secondary sun gear 9, the secondary sun gear 9 is connected to the secondary planetary gear 10, the secondary planetary gear 10 meshes with the secondary ring gear 11, and the secondary planetary carrier 15 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com