Horizontal restraint device of ballast bed

A technology of restraint device and ballast bed, which is applied in the field of rail transit, can solve the problems of insufficient lateral restraint of ballast bed structure, short ballast bed maintenance period, insufficient vertical and horizontal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

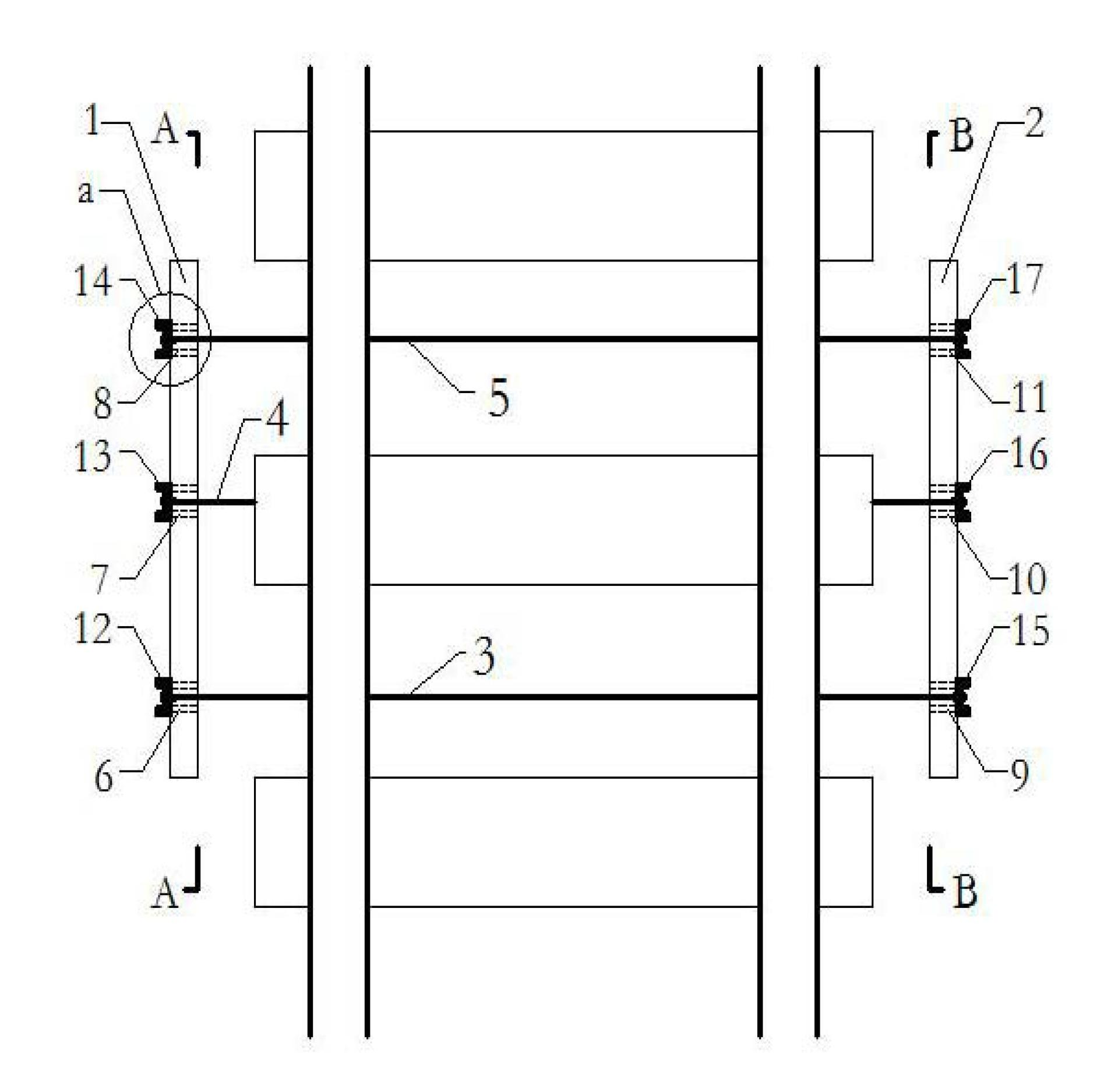

[0026] The present invention will be further described in conjunction with the accompanying drawings.

[0027] A ballast bed lateral restraint device, such as figure 1 , the device includes a reinforced concrete slab 1 on the left side of the line, a reinforced concrete slab 2 on the right side of the line, the first, second, and third wire rope slings 3, 4, 5, and the first to sixth iron casing sleeves 6, 7, 8 , 9, 10, 11, the first to sixth U-shaped bolts 12, 13, 14, 15, 16, 17.

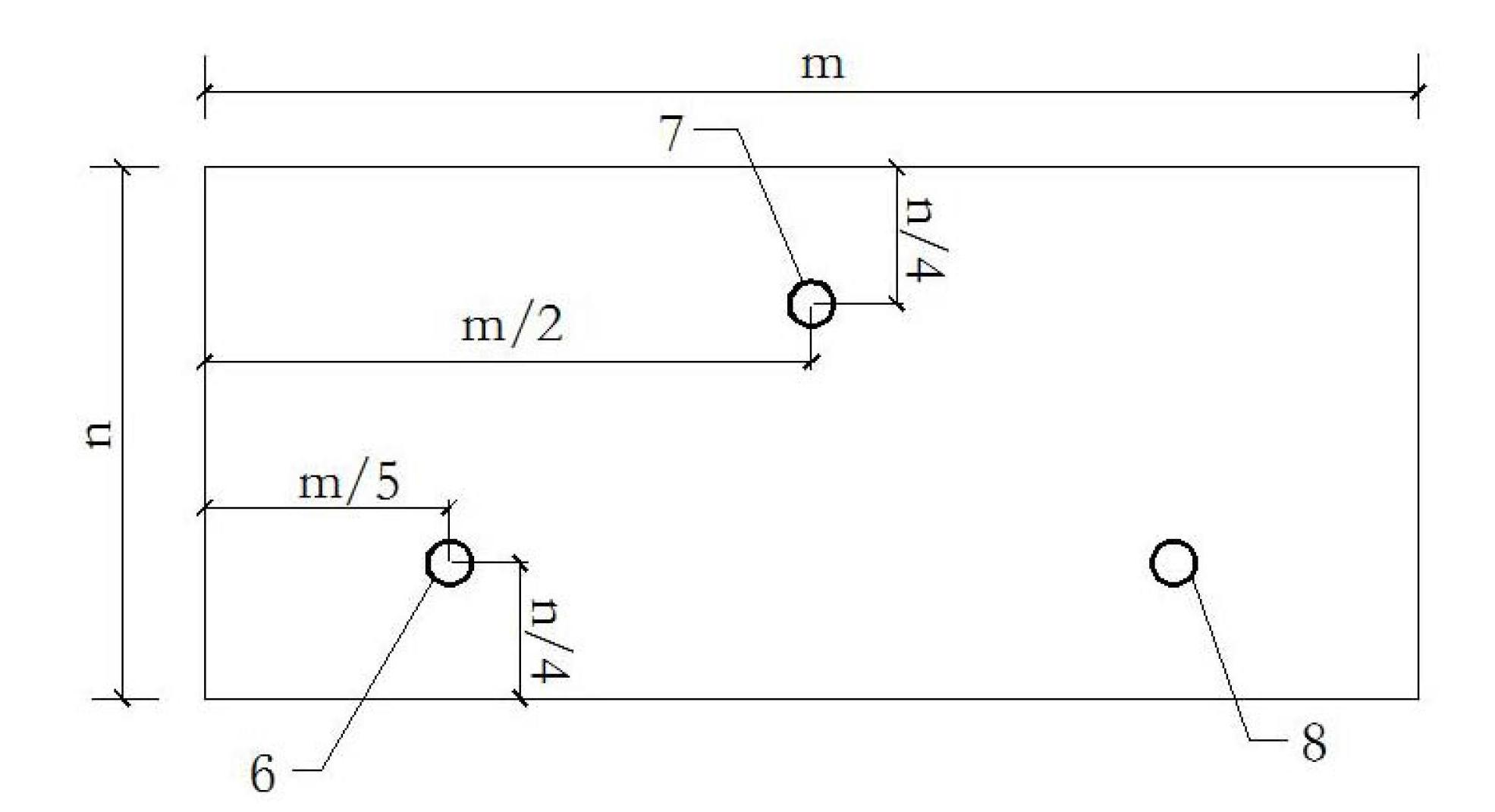

[0028] On the reinforced concrete slab 1 on the left side of the line, the first, second and third iron bushing sleeves 6, 7 and 8 are pre-embedded, such as figure 2 .

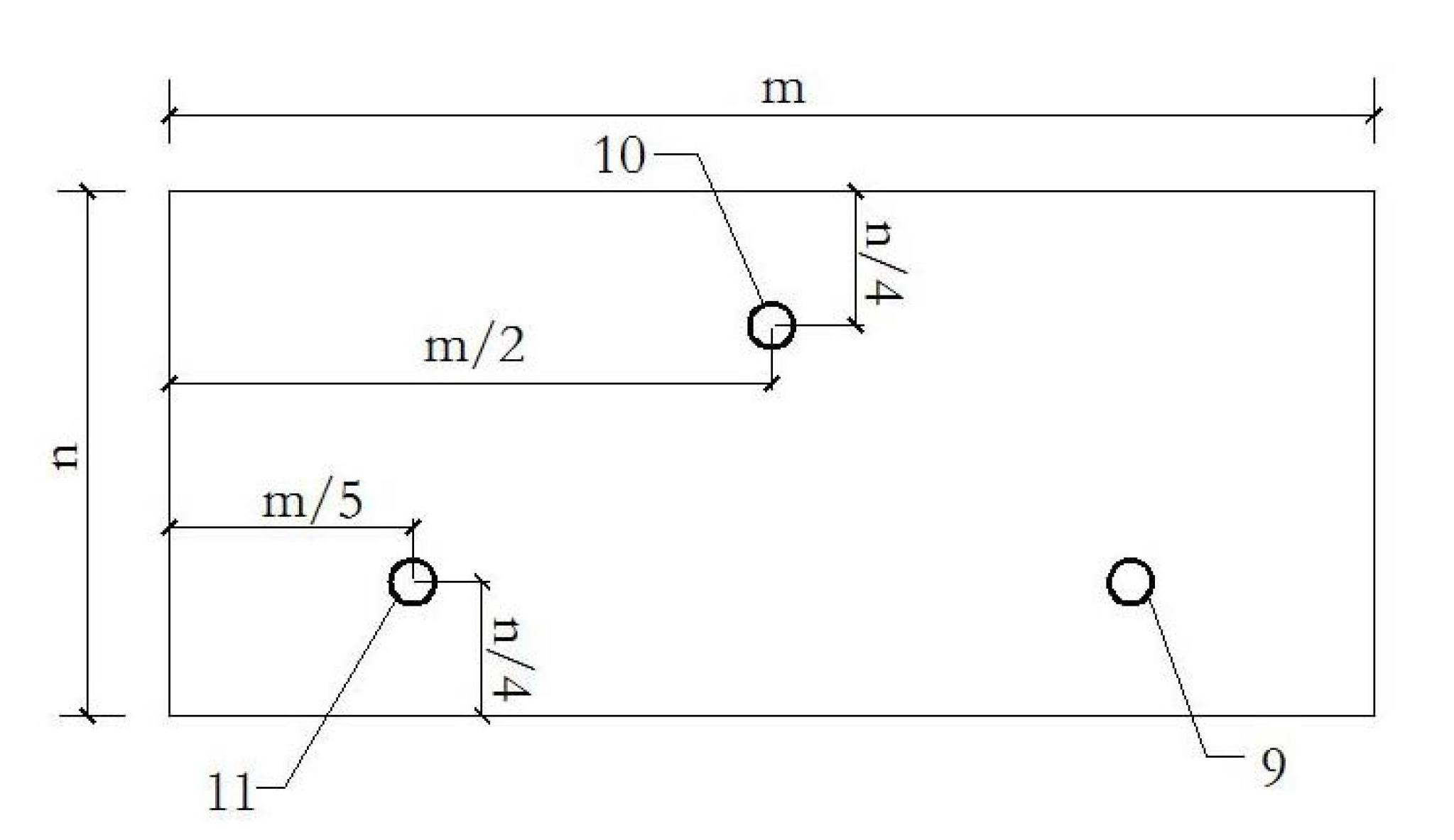

[0029] On the reinforced concrete slab 2 on the right side of the line, the fourth, fifth and sixth iron bushing sleeves 9, 10 and 11 are pre-embedded image 3 .

[0030] One end of the first wire rope rigging 3 passes through the first iron sleeve sleeve 6 on the reinforced concrete slab 1 on the left side of the line, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com