Rigid frame pile supporting and blocking structure

A technology of retaining structure and rigid frame, which is applied in the direction of foundation structure engineering, excavation, construction, etc., can solve the problems of large pile section size, large external pile length, affecting structural safety, etc., achieve reasonable internal force distribution, reduce pile length, The effect of excellent structural rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below with reference to accompanying drawing of specification sheet and specific embodiment:

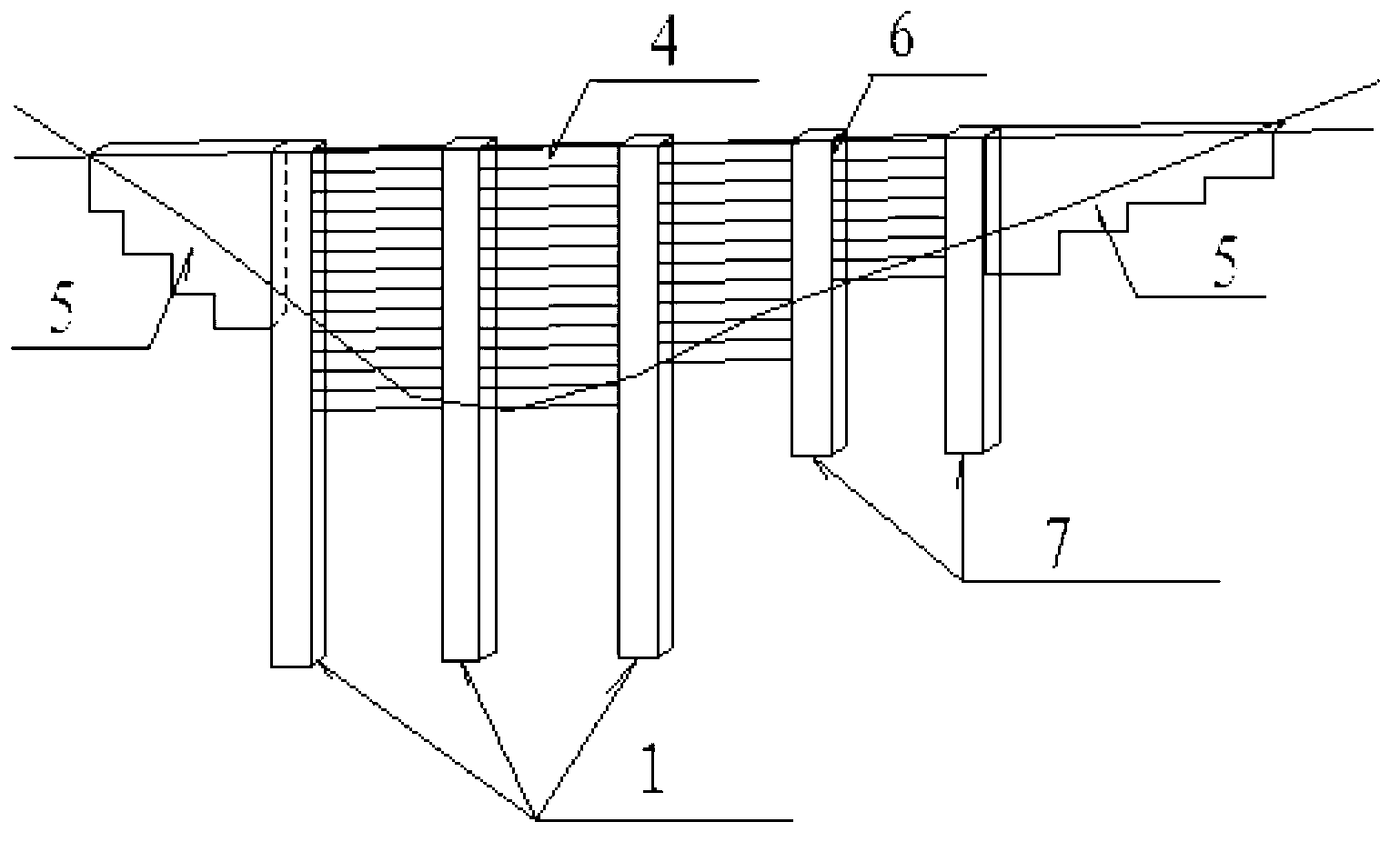

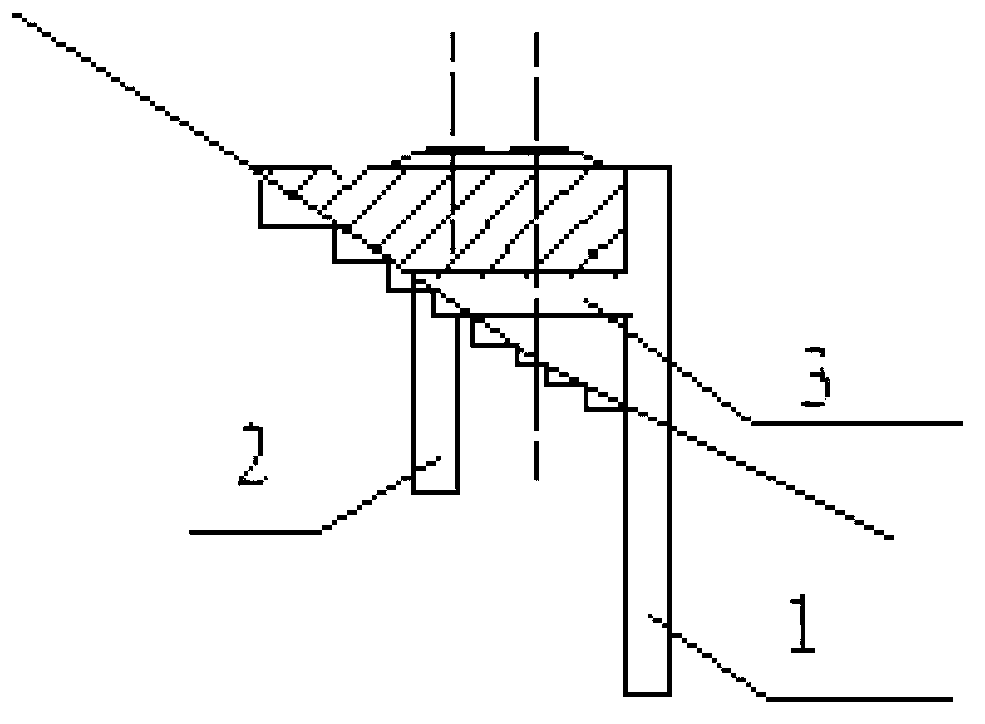

[0016] The invention provides a rigid frame pile support structure, which includes a plurality of h-shaped piles arranged at intervals in the transverse direction. The h-shaped piles include an outer anchor pile 1, an inner anchor pile 2 and a beam 3, the pile top of the inner anchor pile 2 and The pile bodies of the outer anchor piles 1 are connected by a beam 3, and the adjacent outer anchor piles 1 are connected by a retaining plate 4, and the outer anchor piles 1 pass through the rock and soil and are anchored in a stable foundation, and the inner anchor piles 2 and the beams 3 are both Embedded in the rock and soil body, the outer anchor pile 1 is arranged on the outer side of the steep slope, and the inner anchor pile 2 is arranged on the inner side of the steep slope. The soil retaining plate 4 is arranged on the inner sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com