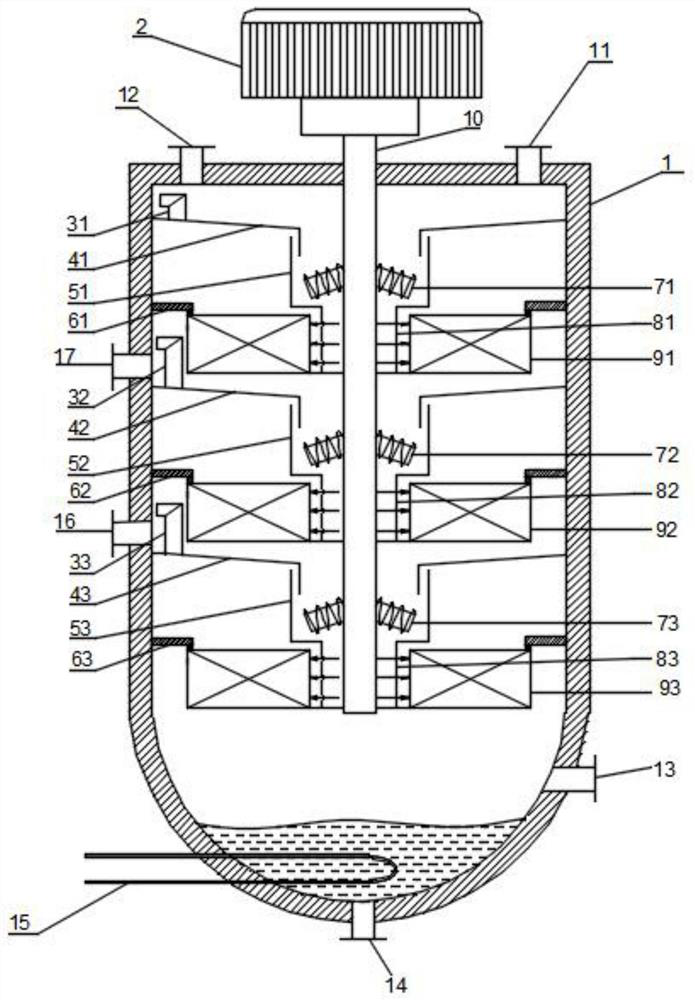

Liquid self-accelerating multi-stage supergravity device and application

A technology of supergravity and liquid, which is applied in chemical methods for liquid-liquid reactions, feeding devices, chemical/physical/physicochemical fixed reactors, etc., which can solve the problems of inability to achieve liquid acceleration, uneven liquid flow rate, and liquid Uneven distribution and other problems, to achieve the effect of increasing the effective mass transfer specific surface area, reducing the volume of the equipment, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

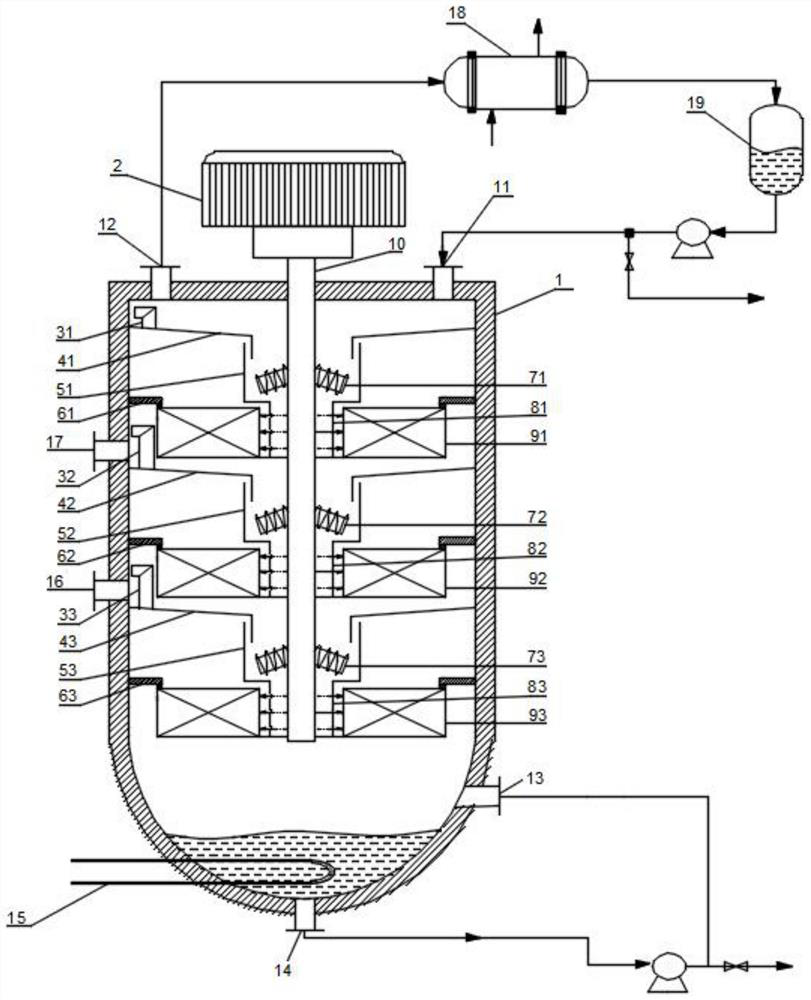

[0097] see figure 2 As shown, a kind of liquid self-accelerating multistage hypergravity device of the present invention is applied to ethylene-ethane system rectification and separation of ethylene and ethane, and the steps are as follows:

[0098] S1: the raw material enters the supergravity device from the primary feed port 16, opens the supergravity device, opens the tower kettle reboiler to heat the material, opens the tower top condenser 18, and closes the reflux;

[0099] S12: when 60% liquid level appears in the tower top condensing tank 19, the reflux is opened, and the liquid enters the supergravity device from the tower top condensing tank 19 from the reflux liquid inlet 11 to maintain a full reflux state;

[0100] S13: After the composition of the material at the top of the tower and the material in the tower reactor is stable, open the material discharge port at the top of the tower and the material discharge port at the bottom of the tower, continuously feed raw...

Embodiment 2

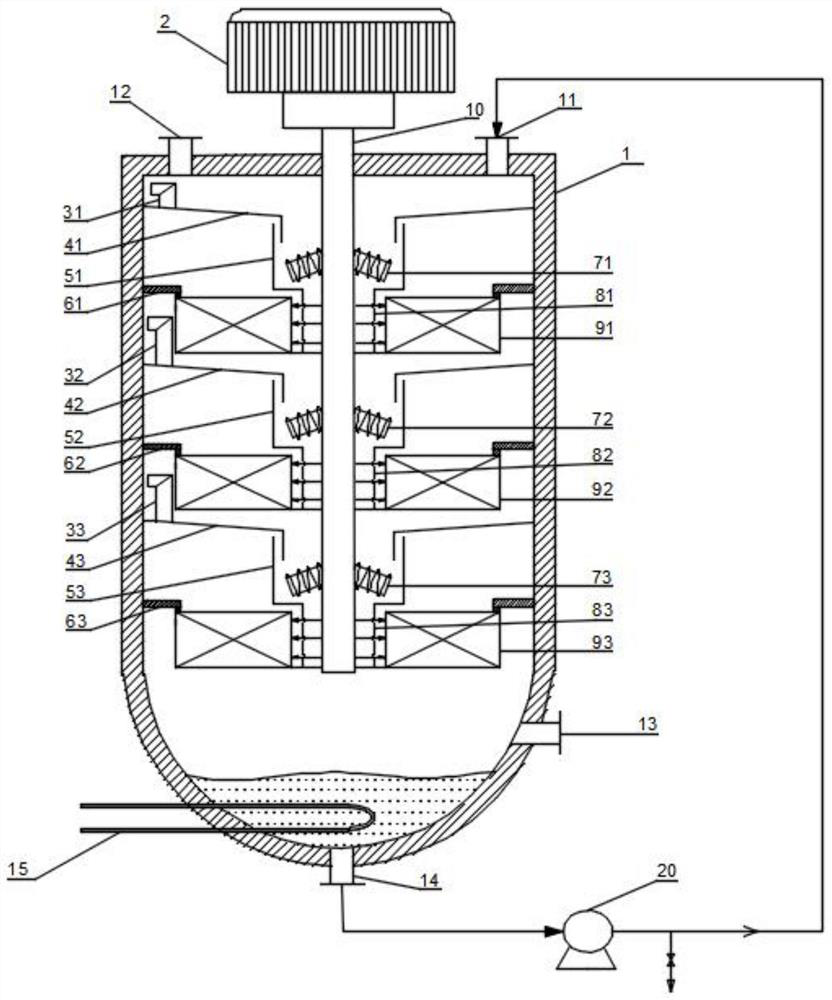

[0105] see image 3 As shown, a liquid self-accelerating multistage supergravity device of the present invention is applied to the alkylation reaction of carbon tetraalkane and carbon tetraalkene to prepare isooctane, and the steps are as follows:

[0106] S21: Connect the liquid outlet to the circulating pump 20 through a pipeline, and then connect it to the return liquid inlet 11 through a pipeline;

[0107] S22: Turn on the supergravity device, and the reaction material enters the supergravity device from the reflux liquid inlet 11;

[0108] S23: After the reaction material is intensified by the multi-stage hypergravity device, it is circulated into the hypergravity device through the circulation pump 20, and the qualified liquid product is extracted from the liquid outlet 14.

[0109] In step S23, the reaction time is 10-30 min.

[0110] In the specific application, after adding the internal components of the liquid speed-up in the multi-stage supergravity rectification,...

Embodiment 3

[0112] see Figure 4 As shown, a kind of liquid self-accelerating multistage hypergravity device of the present invention is applied to α-methylstyrene hydrogenation reaction, and the steps are as follows:

[0113] S31: packing catalyst particles in the filler;

[0114]S32: Turn on the supergravity device, and the gas material is taken in from the gas inlet 13;

[0115] S33: the liquid material enters the supergravity device from the primary feed port 16 or the secondary feed port 17; the liquid outlet 14 is connected to the circulating pump 20 through a pipeline, and then connected to the reflux liquid inlet 11 through a pipeline, and the reaction is cyclic;

[0116] S34: After the reaction material is strengthened by the multi-stage supergravity device, it is extracted from the liquid outlet.

[0117] In the specific application, the contact between the gas, liquid and solid of the present invention is more sufficient, and the hydrogenation conversion rate of α-methyl styr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com