Low pressure drop z-type radial centrifugal flow fixed bed reactor

A fixed bed reactor and radial centrifugation technology, applied in chemical instruments and methods, chemical/physical processes, etc., to achieve the effects of industrial production safety, low perforation speed, and high net ammonia content in the outlet gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

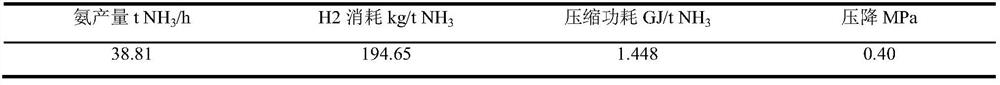

[0060] Taking three existing axial reactor processes loaded with iron-based catalysts as an example, fresh normal temperature and low pressure synthesis gas H 2 / N 2 The ratio is 3.00, the air intake is 5100kmol / h, calculated according to the KBR three-tower process, the synthesis gas enters the first iron-based catalyst reactor with a pressure of 150atm and a temperature of 350°C, and the synthesis gas enters the second and third iron-based catalysts The temperature of the reactor is 380°C, the vent ratio of the recycle gas is 4%, and the catalyst loading capacity of the first iron-based catalyst reactor is 15m 3 , the catalyst loading capacity of the second iron-based catalyst reactor is 25m 3 , the catalyst loading capacity of the third iron-based catalyst reactor is 40m 3 , the final export ammonia concentration is 20.92%, and the production index is shown in Table 1.

[0061] Table 1 Reaction pressure 150atm, H 2 / N 2 = 3.0 iron catalyst production index value

[00...

Embodiment 2

[0064] Taking two existing axial reactors loaded with iron-based catalysts in series and one existing axial reactor process loaded with ruthenium-based catalysts as an example, the intake air volume is 5100 kmol / h, fresh normal temperature and low pressure synthesis gas H 2 / N 2 The ratio is 3.00, the pressure of the synthesis gas entering the iron-based catalyst reactor is 150atm, the temperature of the synthesis gas entering the first iron-based catalyst reactor is 350°C, and the temperature of the synthesis gas entering the second iron-based catalyst reactor is 380°C, The reaction temperature entering the third ruthenium-based catalyst reactor is 360°C. The venting ratio of recycle gas is 4%, and the catalyst loading capacity of the first iron-based catalyst reactor is 15m 3 , the filling capacity of the second iron-based catalyst reactor is 40m 3 , the catalyst loading capacity of the third ruthenium-based catalyst reactor is 9m 3 ,, the final export ammonia concentrati...

Embodiment 3

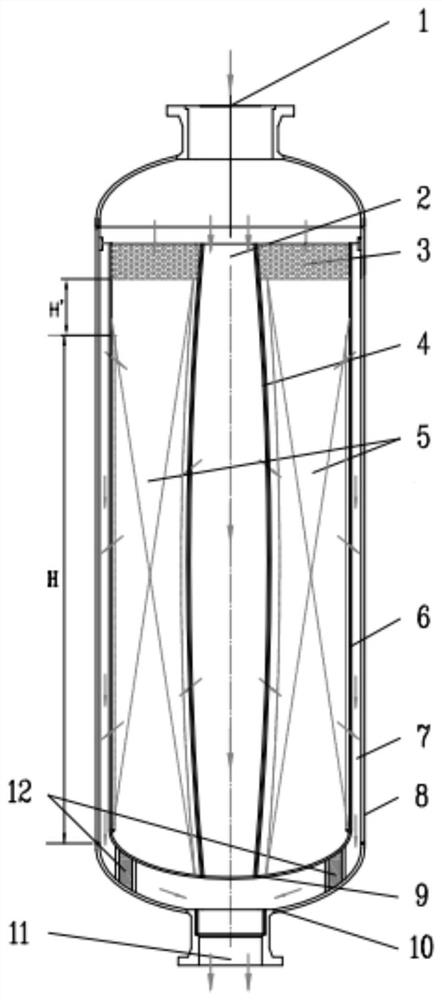

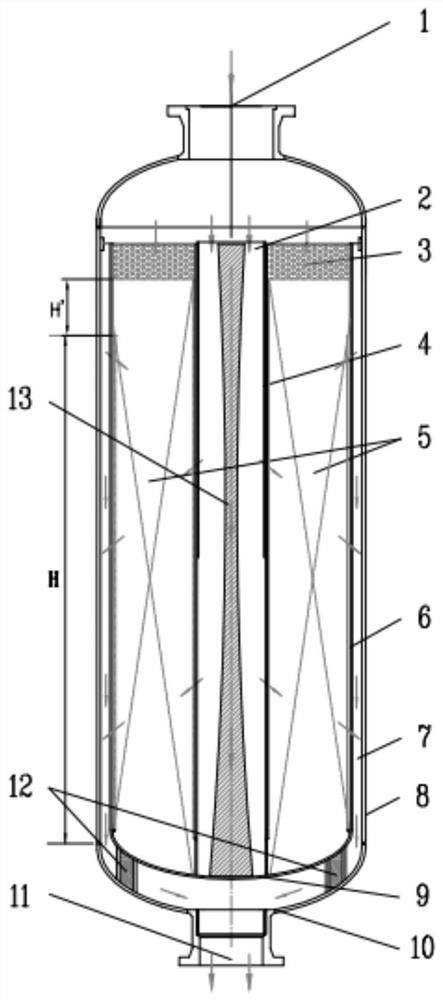

[0068] A Z-type radial centrifugal flow fixed-bed reactor of the present invention packed with a ruthenium-based catalyst is connected in series with two existing axial reactors filled with an iron-based catalyst, as attached figure 1 , 2 The device shown is an example, the intake air volume is 5100kmol / h, and the fresh normal temperature and low pressure syngas H 2 / N 2 The ratio is 3.00, the pressure of the synthesis gas entering the iron-based catalyst reactor is 150atm, the temperature of the synthesis gas entering the first iron-based catalyst reactor is 350°C, and the temperature of the synthesis gas entering the second iron-based catalyst reactor is 380°C, The reaction temperature entering the third ruthenium-based catalyst reactor is 360°C. The venting ratio of recycle gas is 4%, and the catalyst loading capacity of the first iron-based catalyst reactor is 15m 3 , the filling capacity of the second iron-based catalyst reactor is 40m 3 , the catalyst loading capacit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com