A high-speed deformation connection method and device for dissimilar metal plates

A technology of dissimilar metals and connection methods, applied in metal processing equipment, welding equipment, non-electric welding equipment, etc., can solve the problems of uneven axial distribution of pulse magnetic pressure, low coil structure strength, and high equipment requirements, so as to improve energy Utilization rate, improvement of process flexibility, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

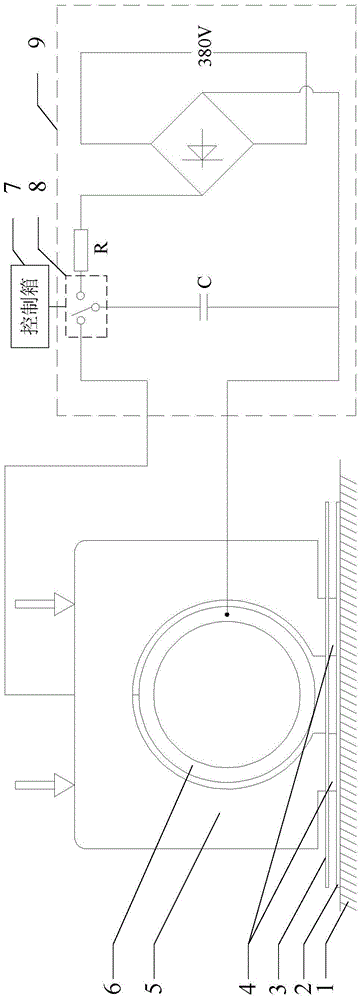

[0028] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, a high-speed deformation connection method for dissimilar metal sheets described in this embodiment, the method is:

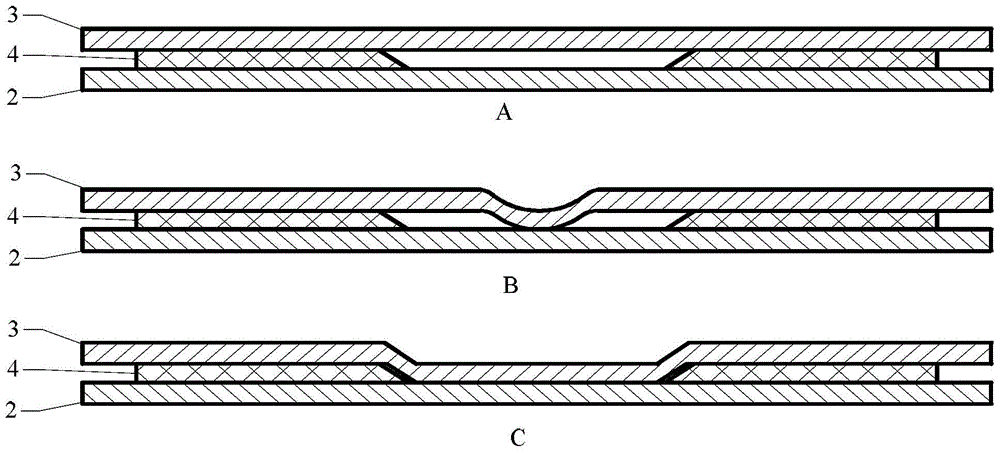

[0029] Place the connected board 2 on the rigid support frame 1,

[0030] Place two insulating partitions 4 on the connected board 2, the thickness of the insulating boards is between 0.5mm-5mm, and there is a gap between the two insulating partitions 4, the spacing is between 3mm-25mm,

[0031] Place the connecting plate 3 on two insulating partitions 4, the thickness of the connecting plate is between 0.2mm-3mm,

[0032] Place the solenoid coil 6 in the induction current channel 5, place the solenoid coil 6 concentrically and coaxially with the induction current channel 5, and the working length of the solenoid coil 6 is greater than the width of the induction current channel 5,

[0033] Press the induction current channel 5 and the connecting plate 3 tightly, ...

specific Embodiment approach 2

[0037] Specific embodiment 2: This embodiment is a further description of the high-speed deformation connection method of a dissimilar metal plate described in specific embodiment 1. In this embodiment, the following steps are performed before the method: the connected plate 2 and The joint surface to be connected of the connecting plate 3 is cleaned, and the contact surface between the induced current channel 5 and the connecting plate 3 is cleaned to reduce the contact resistance.

[0038] In this embodiment, the joint surfaces of dissimilar metal plates to be joined are cleaned, such as steel brush or sandpaper for rust removal, acetone cleaning for degreasing, etc., to ensure that the contact surfaces are smooth and smooth.

specific Embodiment approach 3

[0039] Embodiment 3: This embodiment is to further explain the high-speed deformation connection method of a dissimilar metal sheet described in Embodiment 1. In this embodiment, the magnetic pulse deformation connection device 9 is used to oppose the induced current channel The solenoid coil 6 in 5 is energized, and the magnetic pulse deformation connection device 9 includes: a rectifier bridge circuit, a current limiting resistor R, a capacitor C and a single-pole double-throw switch 8;

[0040] The rectifier bridge circuit is used to rectify the external AC voltage into a DC voltage. The positive pole of the DC voltage of the rectifier bridge circuit is connected to one end of the current-limiting resistor R, and the other end of the current-limiting resistor R is connected to a static end of the single-pole double-throw switch 8. The rectifier bridge circuit The negative pole of the DC voltage is connected to the negative terminal of the capacitor C and a terminal of the sole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com