A radial flow residual oil hydrotreating reactor

A residue hydrogenation and reactor technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems such as the inability to realize the reaction process of radial flow fixed bed residue hydrogenation, and improve the utilization rate of active resources. , maximize the utilization rate of active resources, and facilitate the effect of hydrogenation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

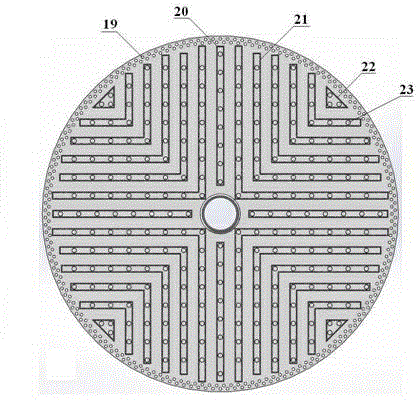

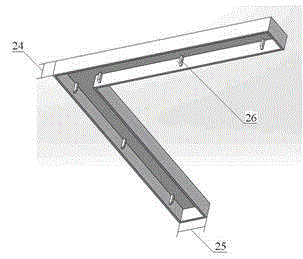

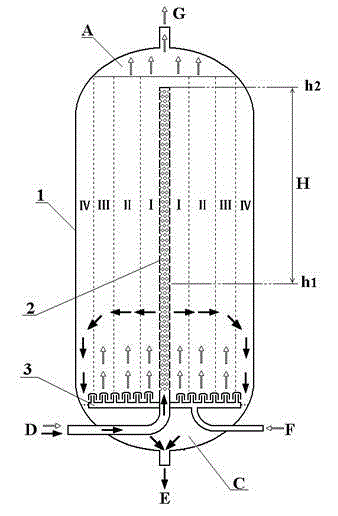

[0030] The structure and principle of the radial flow residual oil hydrogenation reactor of the present invention will be further described below in conjunction with the accompanying drawings. The following drawings are only used to illustrate the structure and principle of the radial flow residual oil hydrogenation reactor of the present invention, and do not constitute any specific limitation to the present invention.

[0031] figure 1 Among them, 1 is the reactor shell, 2 is the oil inlet pipe of the central axis, 3 is the hydrogen gas distribution plate, 4 is the hydrogen gas inlet, 5 is the output of the produced oil, 6 is the feed oil inlet pipe, 7 is the gas outlet, and 8 is the conical pipe , 9 is the gas pipe. A represents the gas collection area, B represents the hydrogenation reaction area, and C represents the generated oil collection area. In the figure, there is a virtual interface between area A and area B. In fact, when no catalyst is filled, there is no boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com