Filter tubes and preparation method thereof

A filter tube and tube body technology, applied in the field of filter tube and filter tube preparation, can solve the problems of limited filter area improvement, low-cost filter area, and waste of small-area porous film, achieving low cost and high filtration The effect of temperature and working surface shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

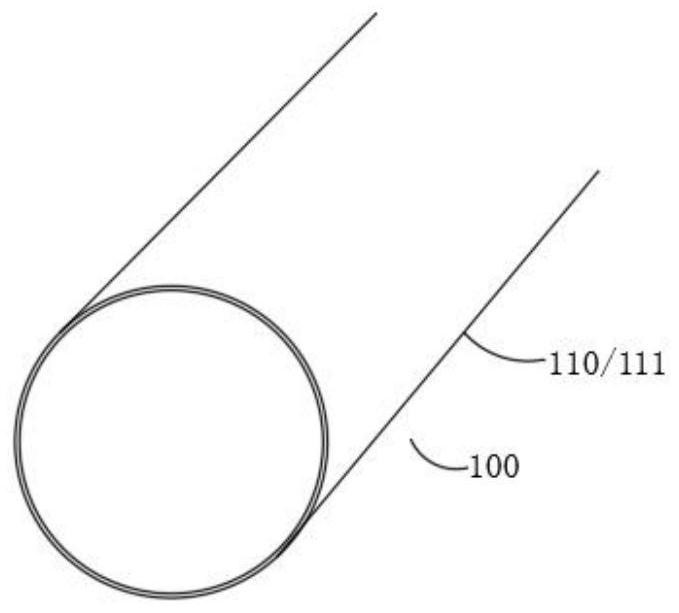

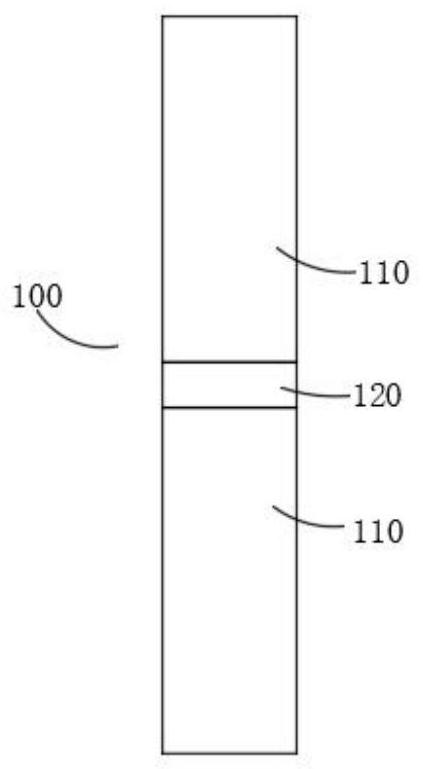

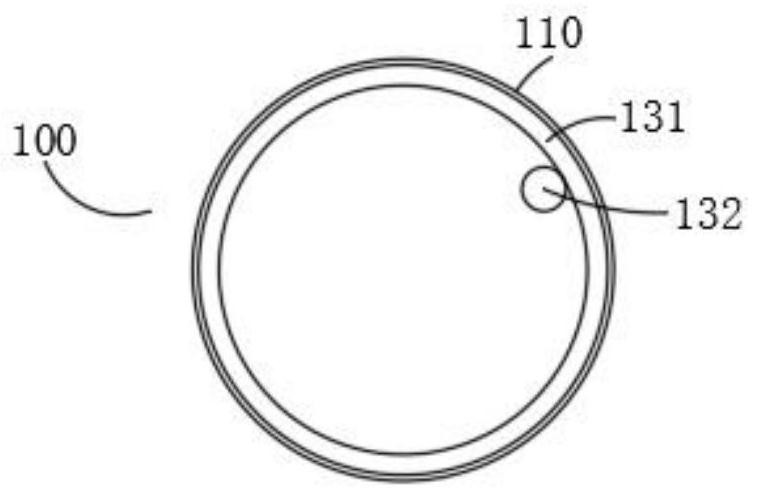

[0134] In addition, the present invention provides a method for preparing the above-mentioned filter tube 100, which includes the steps of: rolling a thin sheet material 111 with a thickness of 0.2-2.5 mm into a tube body 110 with an outer diameter of 20-200 mm, fixing and sealing the seam 112 Welded or glued.

[0135] Figure 4 It is a tube body obtained by rolling in a specific embodiment. Such as Figure 4 As shown, the seam 112 of the tube body 110 is parallel to the central axis of the filter tube 100 , and the tube body 110 is obtained by butting the long side of the rectangular sheet material 111 whose wide side matches the diameter of the tube body 110 .

[0136] Figure 5 It is a tube body obtained by rolling in another specific embodiment. Such as Figure 5 As shown, the seam 112 of the pipe body 110 is in the shape of a helix. The pipe body 110 is prepared by the preparation method published in the Chinese invention patent with the application number 2019102093...

specific Embodiment approach

[0204] Figure 20-21 It is a structural schematic diagram of the first specific embodiment of the pressing mechanism. Such as Figure 20-21 As shown, the pressing mechanism includes: a pressing plate 441, the upper joint 210 and the step 330 are clamped between the pressing plate 441 and the first support structure 420; a pressing assembly, the pressing assembly is connected The pressing plate 441 and the first support structure 420 . in, Figure 20 Push-in installation from top to bottom, Figure 21 Push-in installation from bottom to top.

[0205] Figure 22 It is a structural schematic diagram of the second specific embodiment of the pressing mechanism. Such as Figure 22 As shown, the pressing mechanism includes: a pressing plate 441, the step 330 is clamped between the pressing plate 441 and the first support structure 420; a pressing assembly, the pressing assembly is connected to the pressing assembly. Plate 441 , upper joint 210 and first support structure 420 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com