Split type laser focusing device

A focusing device and split-type technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of high processing precision, complex spherical aberration lens design and processing technology, and limited direct application of axicon method and promotion issues, to achieve the effect of high energy utilization and improve the quality of imaging focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

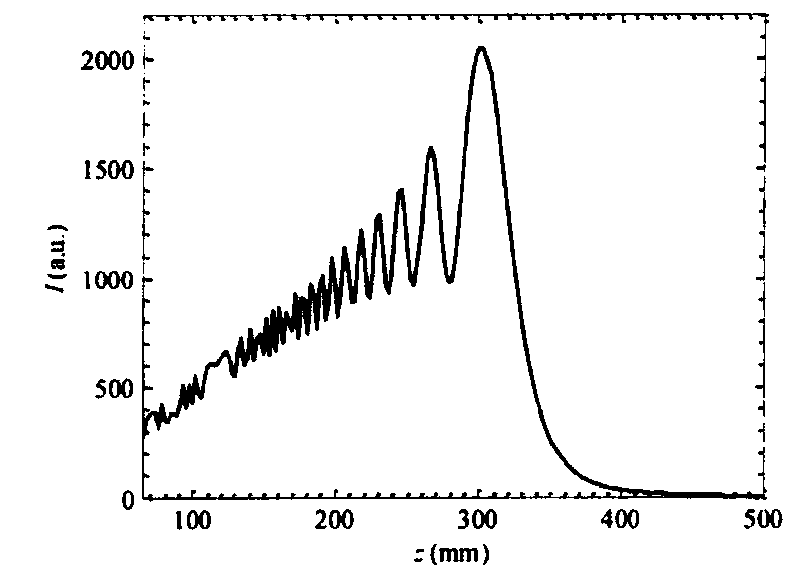

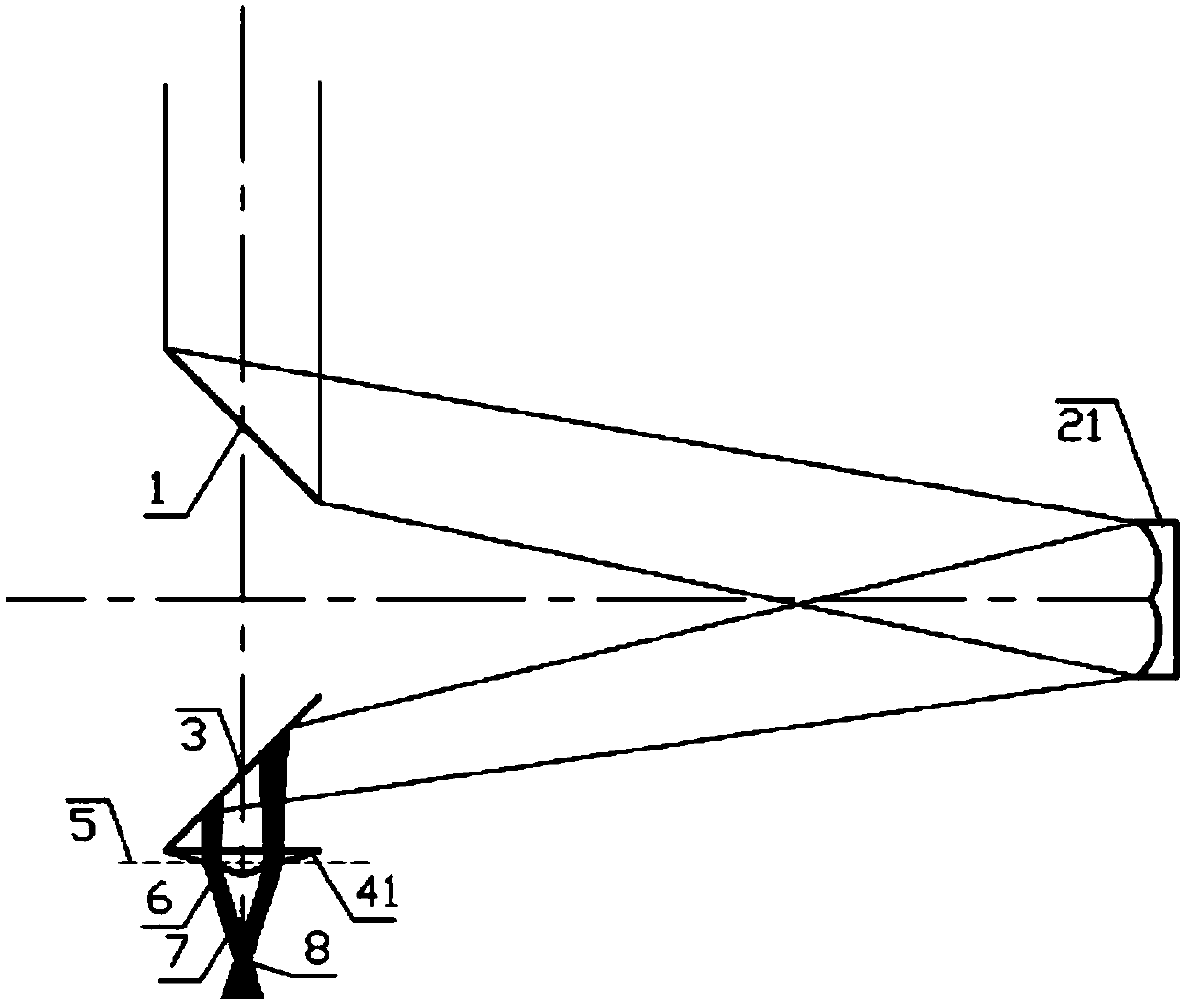

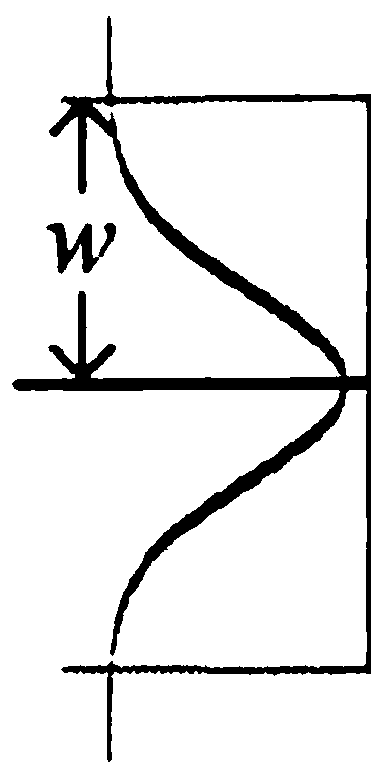

[0057] see figure 2 , the structural diagram of the laser focusing device provided by the first embodiment of the present invention is as follows figure 2 As shown, the laser focusing device is composed of a first reflector, a concave reflector with an annular arc-shaped concave surface, a third reflector, and a conical mirror. The first reflector and the third reflector are both plane reflectors. After being reflected by the first reflector, the incident laser beam is incident on the concave reflector with circular arc-shaped concave surface at a small angle, reflected by the concave reflector with circular arc-shaped concave surface, and then reflected by the third reflector, It enters the conical mirror and exits from the side of the cone. According to the beam focusing requirements, calculate the light field distribution range in the focusing device, calculate the base angle of the processed cone, match the refractive index of the cone material, process the cone accordi...

Embodiment 2

[0071] The structural schematic diagram of the laser focusing device provided by the second embodiment of the present invention is as follows: Figure 13 As shown, the laser focusing device is composed of a first reflector, an equivalent Fresnel reflector, a third reflector, and a circular table mirror, and the first reflector and the third reflector are both plane reflectors. After being reflected by the first reflector, the incident laser beam is incident on the equivalent Fresnel reflector at a small angle, reflected by the equivalent Fresnel reflector, and then reflected by the third reflector, enters the circular table mirror, and exits from the side of the circular table . The split-type laser focusing device, according to the beam focusing requirements, calculates the distribution range of the light field in the focusing device, calculates the size of the bottom angle of the processed frustum, matches the refractive index of the material of the frustum, and processes th...

Embodiment 3

[0078] The second reflector is a Fresnel reflector equivalent to a concave reflector having an annular arc-shaped concave surface. Other technical features of this embodiment are the same as those of Embodiment 1. In this example, the second reflector is the equivalent Fresnel reflector of the second embodiment of the present invention. Compared with the concave reflector with circular arc-shaped concave surface of the first embodiment, the equivalent Fresnel reflector The reflector saves more raw materials, is easy to process, and reduces costs. Such as Figure 14 Shown is a structural schematic diagram of the through-center axial section of the equivalent Fresnel reflector of the second embodiment of the present invention, indicating the symmetry of the equivalent Fresnel reflector about the axis. Such as Figure 15 shown as Figure 14 , indicating the rotational symmetry of the equivalent Fresnel mirror about the center of the left view, combined with Figure 14 , the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com