Process and system for vibration hot-pressing dehydration and quality improvement of brown coal

A technology for lignite and process, which is applied in the field of lignite vibrating hot-pressing dehydration and upgrading technology and system, can solve the problems of easy re-absorption of lignite and uneven distribution of hot-pressing dehydration pressure, and achieves shortened heating time, good industrial application prospect, and process system. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: the technical steps of upgrading are as follows:

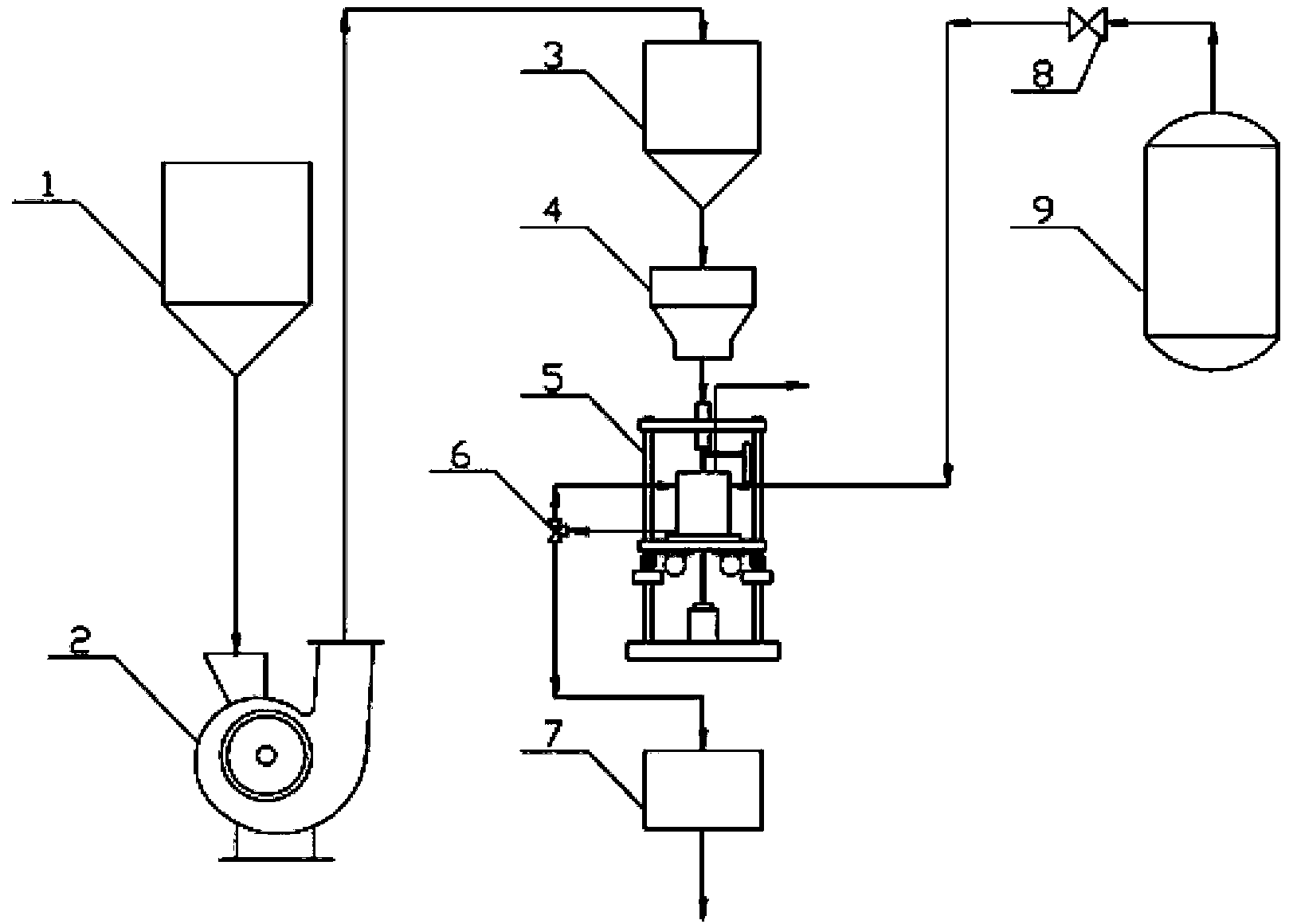

[0026] A) The lignite in the raw coal bunker 1 is crushed to less than 3mm by the fan milling pre-drying device 2 and sent to the pulverized coal bunker 3, and the lignite is sent to the vibrating hot-press dehydration and upgrading device 5 through the material distribution device 4, and sealed after preheating;

[0027] B) Steam is introduced into the vibrating hot-press dehydration and upgrading device 5 to heat the lignite to the process temperature, the temperature is 150-220°C, and the pressure is 5-12MPa; the steam generated by the steam generating device 9 is directly contacted with the coal material for heating, and the steam The steam generated by the boiler is used to dehydrate and form the lignite by vibration and hot pressing. The static pressure of the forming is 5~12MPa; the vibration excitation force and frequency can be adjusted;

[0028] C) After dehydration and molding, demoulding, after...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com