Linear electric motor with movable armature core

An armature core and linear motor technology, applied in the field of armature core movable linear motors, can solve the problems of low motor performance-to-volume ratio, uneven distribution of excitation magnetic field along the axial direction, etc., to achieve improved performance-to-volume ratio and uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

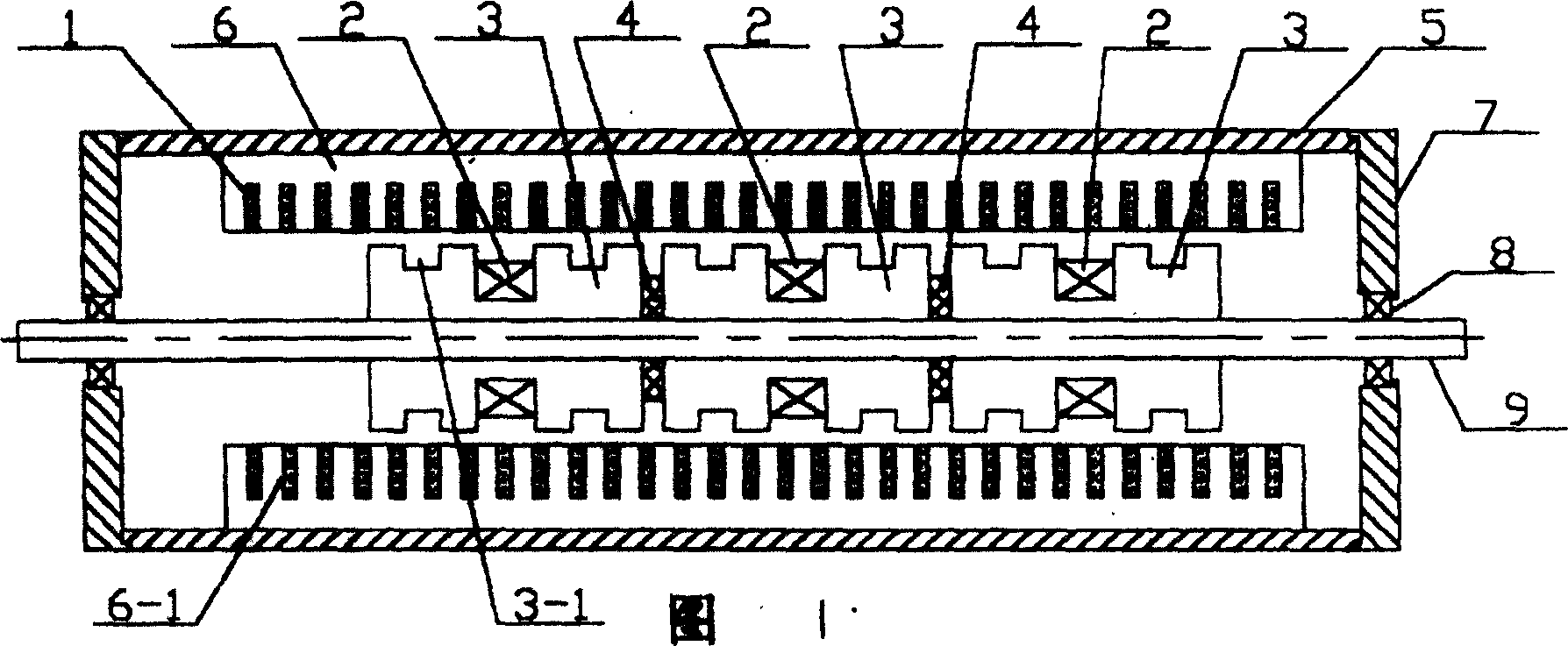

[0007] Embodiment: a linear motor with a movable armature core, two end covers 7 are respectively connected to both ends of the casing 5, the outer rings of the two bearings 8 are respectively fixed in the inner holes of the two end covers 7, the bearings 8 The inner ring is fixedly connected with the shaft 9, the armature core 3 is set on the shaft 9, the outer circular surface of the cylindrical non-armature core 6 is closely matched with the inner surface of the casing 5, the armature core 3 and the non-armature core An air gap 10 is formed between the 6. The armature core 3 and the non-armature core 6 face the air gap 10 on the surface of which there are annular cogging in sequence along the axial direction. The permanent magnet 1 is arranged on the cogging 6 of the non-armature core 6. -1 in.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com