Integrated feeder

A feeder and feeding roller technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems affecting the crushing efficiency of the lower crushing mechanism, uneven axial distribution of materials, and no stone removal mechanism. , to achieve the effect of eliminating damaged sieve plate, uniform axial distribution and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, and the purpose is only to better understand the content of the present invention.

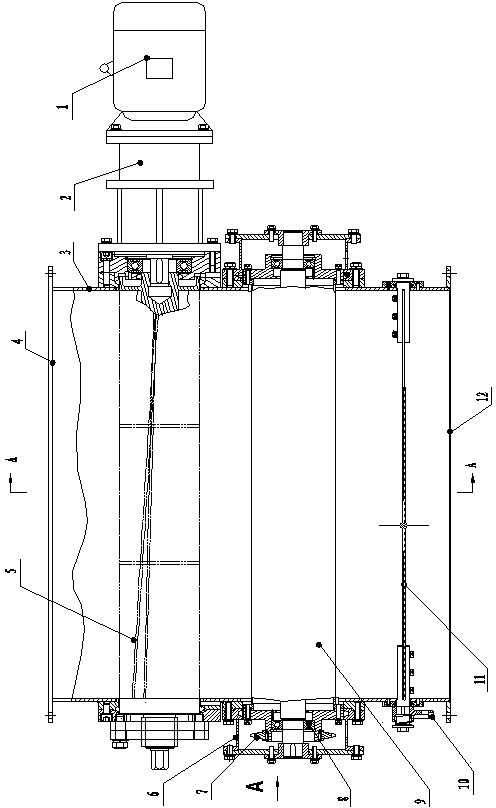

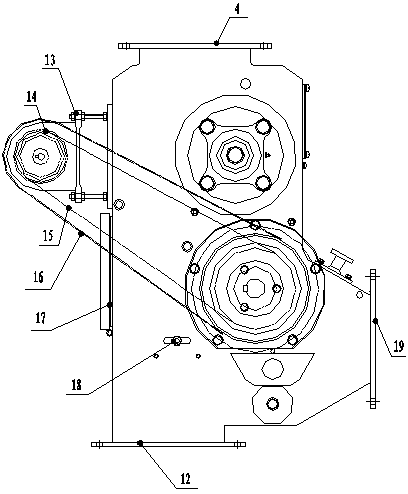

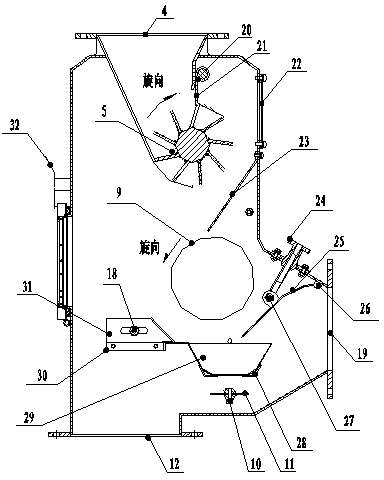

[0025] see figure 1 , figure 2 , image 3 , the side wall of the housing 3 of the integrated feeder provided in this embodiment is provided with an observation door 17, and the top of the observation door 17 is provided with an observation door pressing mechanism 32; The sidewall of 3 is provided with hand hole and hand hole cover 22 is installed.

[0026] The top of the housing 3 is provided with a material inlet 4, the bottom of the housing 3 is provided with a material outlet 12, and the housing 3 is provided with a feeding roller 5, a magnetic separation roller 9, a stone remover 31 and miscellaneous materials in sequence from top to bottom. Object drawer 29, one end of feeding roller 5 is connected with speed reducer 2, motor 1 that are fixed on housing 3 outsides.

[0027] The housing 3 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com