Graphite electrode molding machine

A graphite electrode and forming machine technology, applied in the field of presses, can solve problems such as poor product density uniformity, increased platform load, and difficulty in vacuum forming, so as to meet the requirements of the process, reduce power consumption, and realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

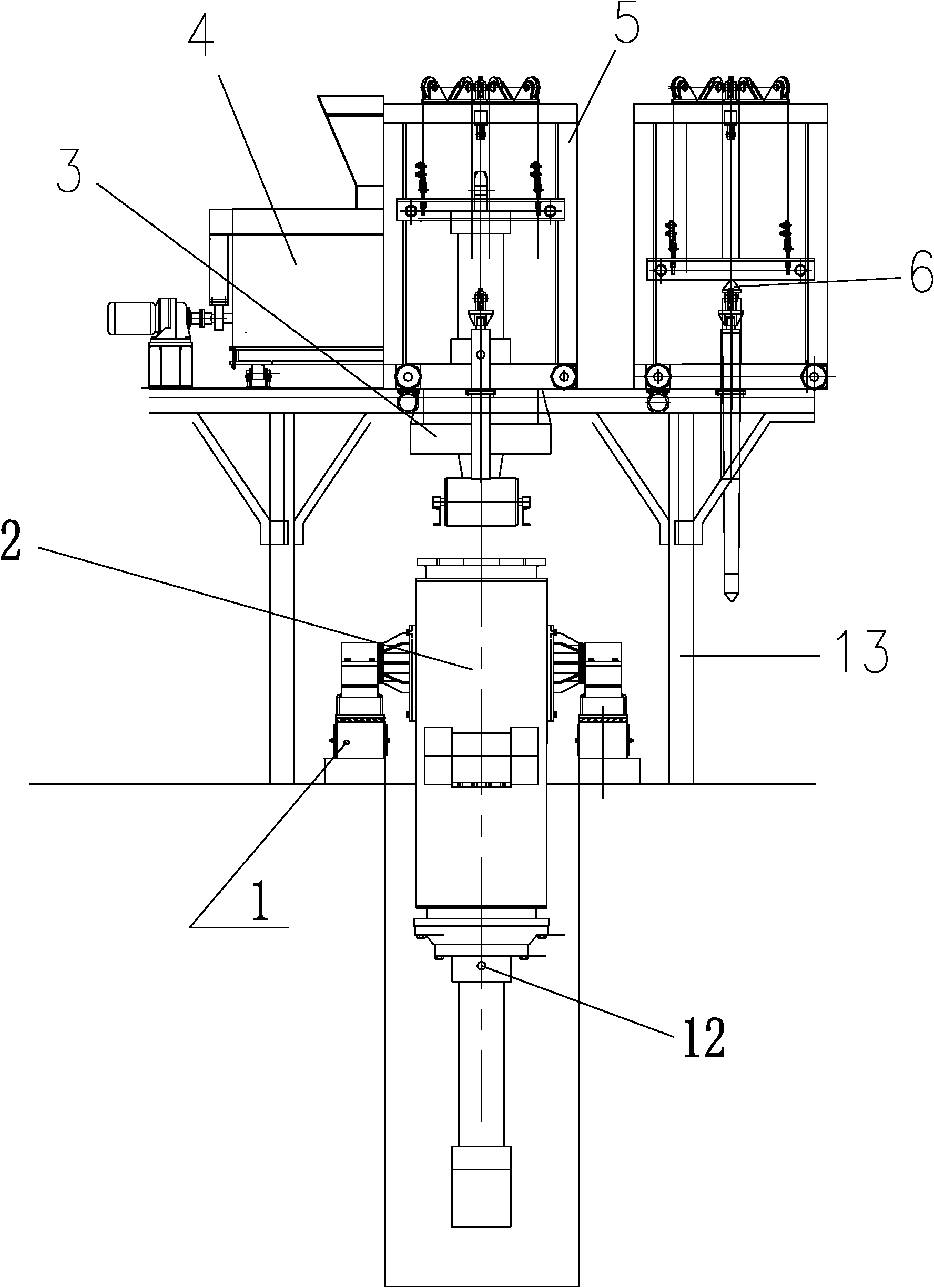

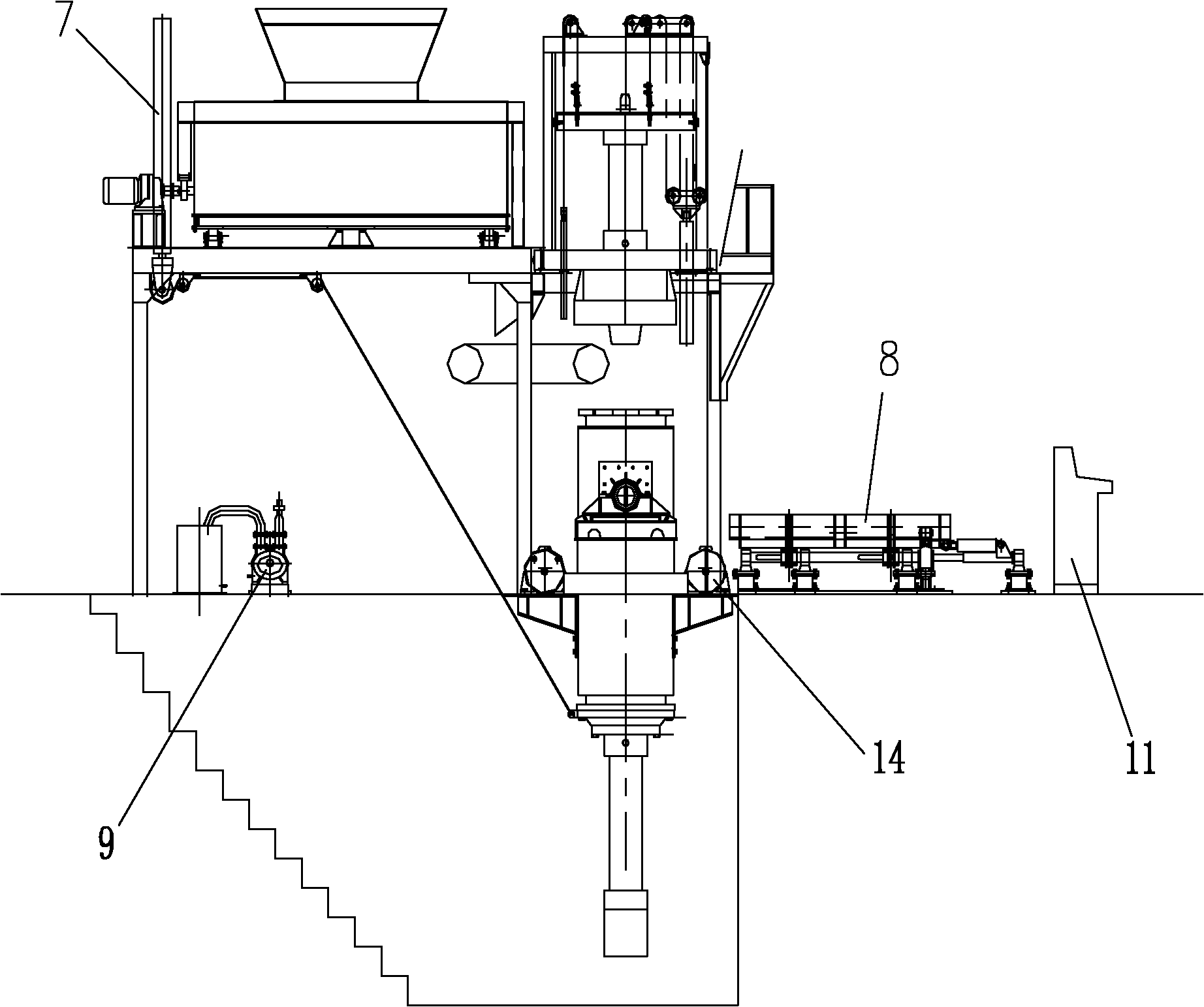

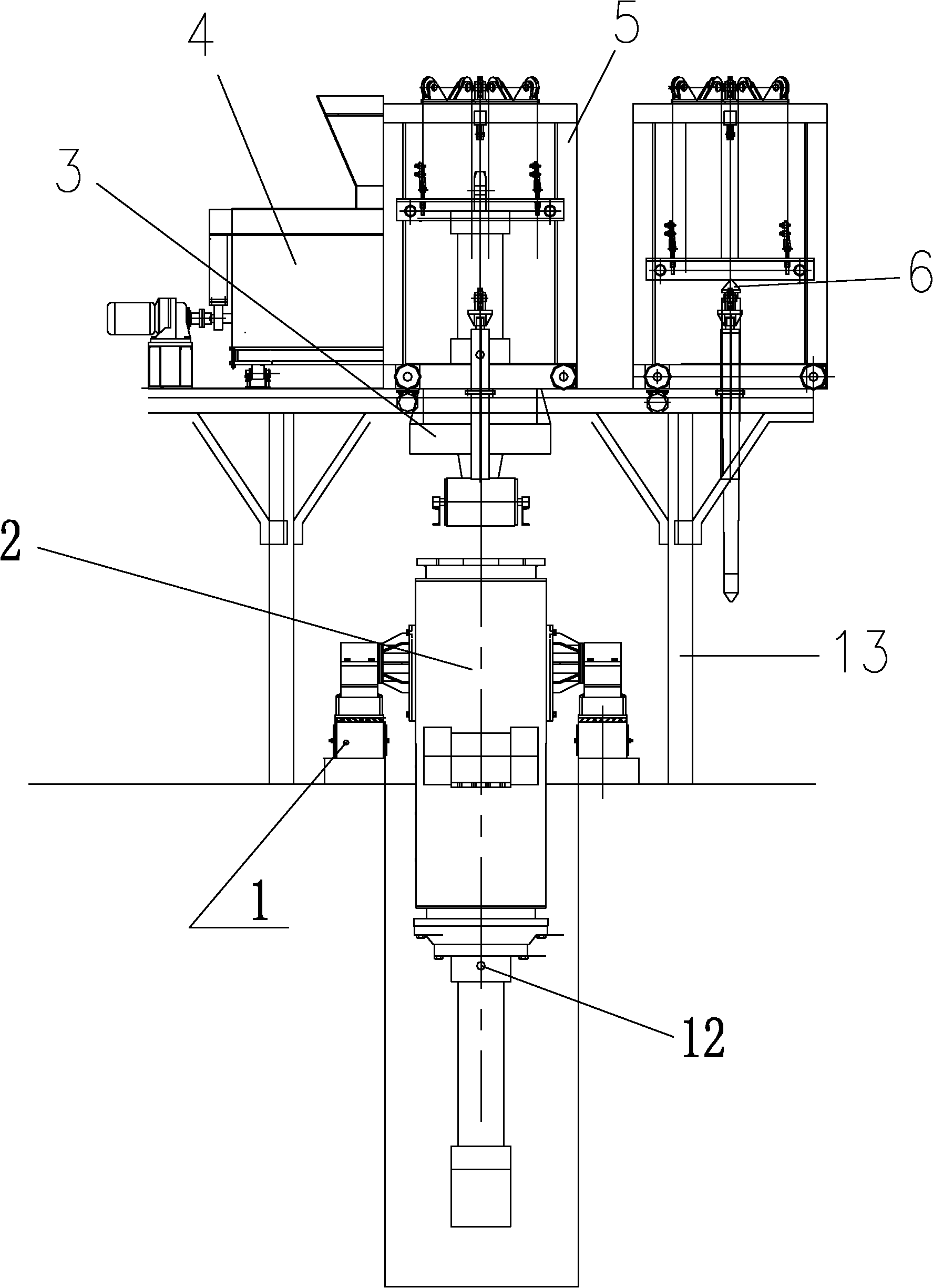

[0025] see figure 1 and 2 , the embodiment of the present invention is provided with electrode trolley 8, vacuum system 9, hydraulic system 10, electric control system 11 and frame 13, also is provided with rubber spring support 1, mold 2, upper pressure head 3, cool material system 4, The upper trolley 5, the core column and the center frame 6, the turning mechanism 7, the lower pressure head 12 and the vibrating motor 14.

[0026] The rotation axis of the mold 2 is set on the rubber spring base 1, the paste outlet of the cold material system 4 is connected to the mold 2 through the belt machine, the upper pressure head 3 and the lower pressure head 12 are connected with the mold 2, and the upper trolley 5 is set on the frame On the track of 13, the upper pressing head 3, the core column and the center frame 6 are arranged on the upper trolley 5, and the vibrating motor 14 is used as a vibration source and arranged on both sides of the mold 2. The vibrating motor 14 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com