Butt joint method of newly-built GIS bus and existing GIS bus and GIS bus system

A busbar system and busbar technology, applied in the direction of fully enclosed busbar devices, connections, cable joints, etc., can solve the problems of high cost, low operation efficiency, and low operation efficiency in the docking process, so as to improve efficiency, improve operation efficiency, and reduce connection The effect of times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

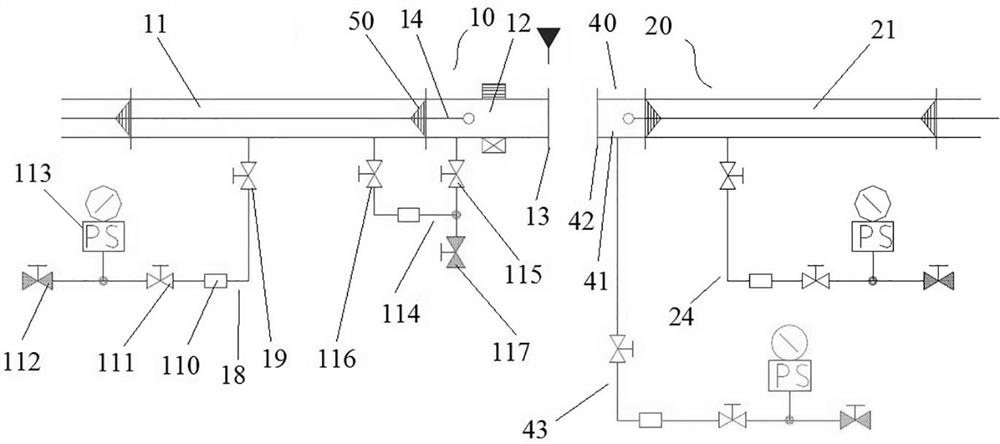

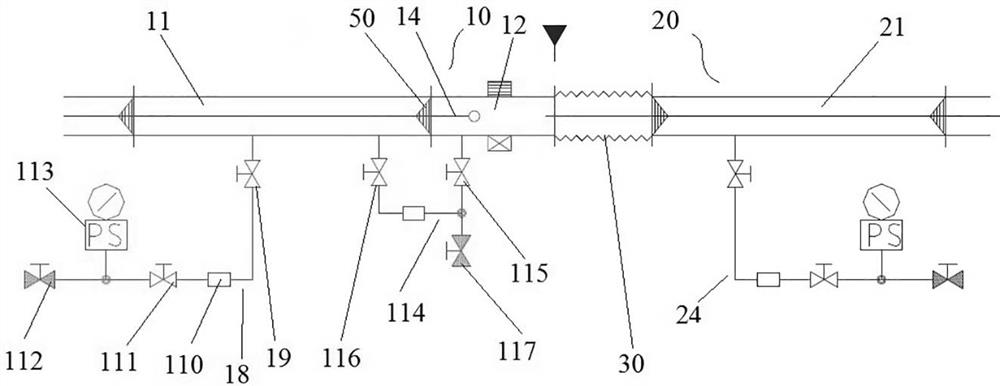

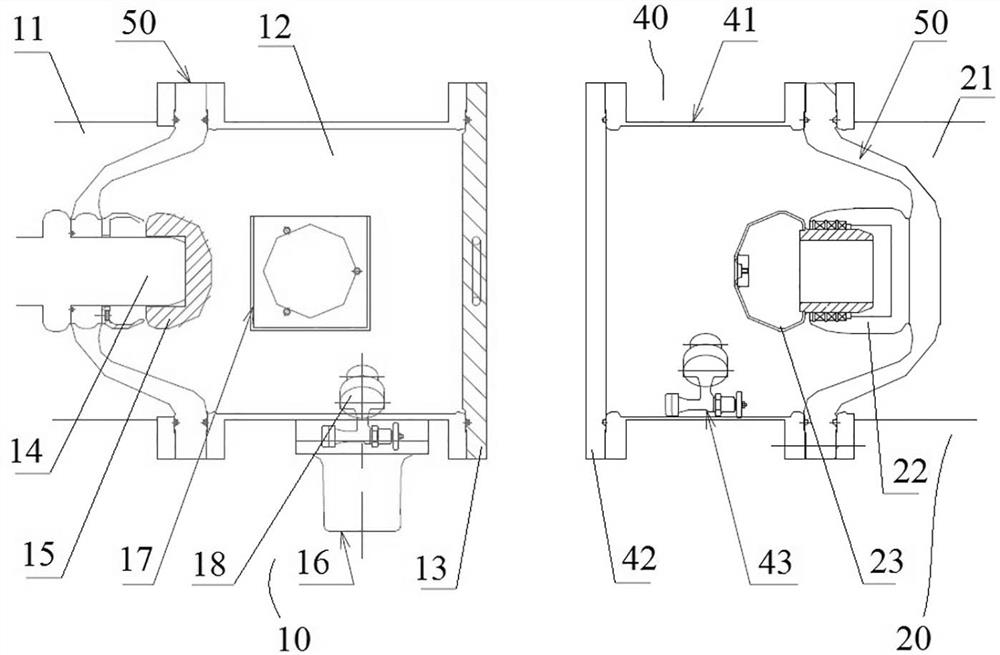

[0063] like figure 1 and figure 2 As shown, the GIS busbar system includes the existing GIS busbar 10, the new GIS busbar 20, the detachable busbar 30 and the test device 40, and the existing GIS busbar 10 and the new GIS busbar 20 are connected by figure 1 , figure 2 and Figure 5 Marking boundaries composed of triangles and straight lines in . Among them, the detachable bus bar 30 (such as figure 2 ) is used to connect between the new GIS bus 20 and the existing GIS bus 10 during docking, which is a structure in the prior art; the test device 40 is used to temporarily connect to the existing GIS bus 10 before the new GIS bus 20 is docked. On the transition bus 21 of the newly-built GIS bus 20, a test is carried out on the newly-built GIS bus 20.

[0064] Existing GIS busbar 10 includes reserved busbar 11, reserved joint barrel 12, reserved cover plate 13 and reserved joint 14 (for reserved joint 14 see Figure 4 and Figure 5 ), the left side of the reserved busbar...

Embodiment 2

[0088] The difference between this embodiment and Embodiment 1 is that in Embodiment 1, a communication pipeline is formed between the charging and deflation device on the reserved joint cylinder 12 and the reserved busbar, while in this embodiment, the reserved joint cylinder 12 The inflation and deflation device on the 12 is an independent inflation and deflation device.

Embodiment 3

[0090] The difference between this embodiment and Embodiment 1 is that, in Embodiment 1, the communication pipeline between the charging and deflation device on the reserved joint cylinder 12 and the reserved busbar includes two valves, while in this embodiment, There is only one valve and a corresponding pipeline for the communication pipeline between the inflation and deflation device on the reserved joint cylinder 12 and the reserved busbar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com