A high power density power battery cooling system

A high power density, power battery technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of increasing the volume and weight of battery packs, unfavorable light weight of electric vehicles, and consuming parasitic power, so as to improve heat dissipation efficiency , uniform axial distribution, and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with reference to the drawings and specific embodiments, but the protection scope of the present invention is not limited to this.

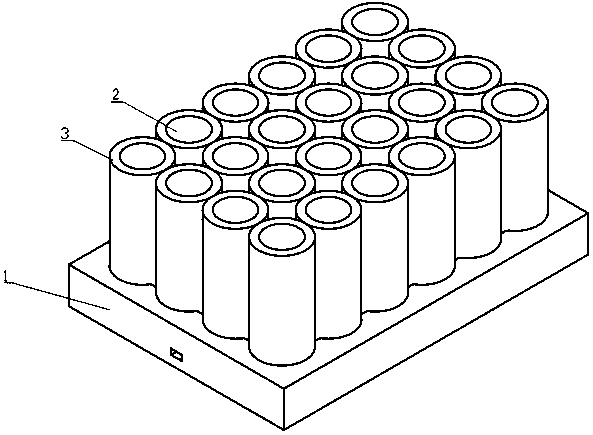

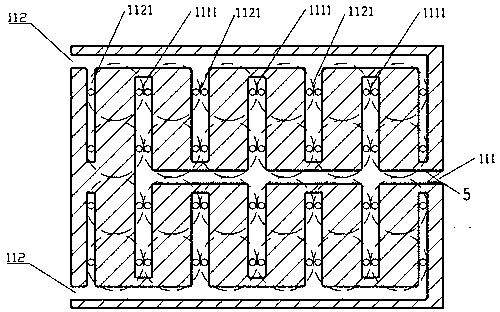

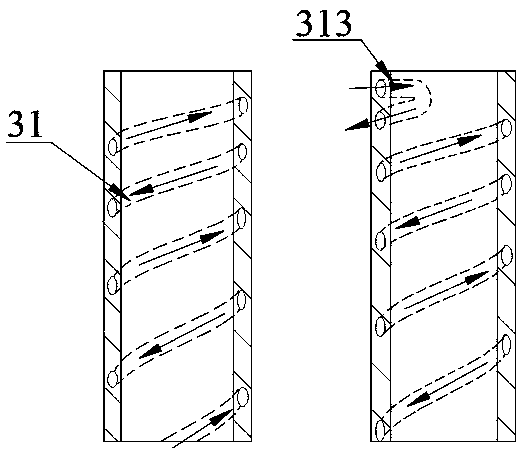

[0029] Such as figure 1 As shown, the high-power density power battery cooling system of the present invention includes a single heat dissipation module and a heat dissipation base 1. The single heat dissipation module includes a power battery 2 and a cooling jacket 3. The power battery 2 is installed in the cooling jacket In 3, the cooling jacket 3 is provided with a cooling runner 31, which can be inside the cooling jacket 3 or on its inner and outer surfaces. Such as image 3 with Figure 4 As shown, the cooling channel 31 cools the inside of the jacket 3. Such as Figure 5 As shown, the bottom of the cooling channel 31 is provided with an inlet 311 and an outlet 312; the inlet 311 and the outlet 312 may be one each, or more than one may be designed as required. A number of the single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com