Micro asymmetric ceramic electrode plug

A ceramic electrode, asymmetrical technology, applied in the direction of weapon accessories, fuzes, offensive equipment, etc., to achieve the effect of good firing reliability, small structural size, and high structural connection force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

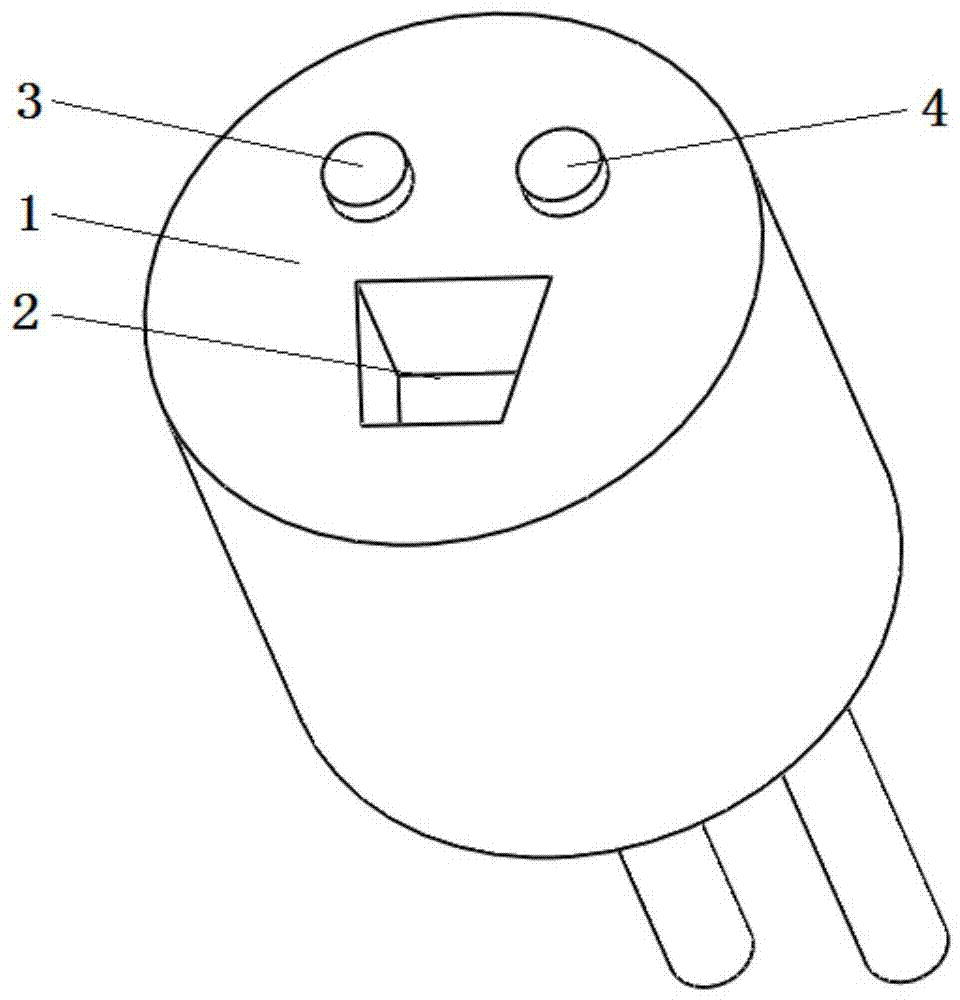

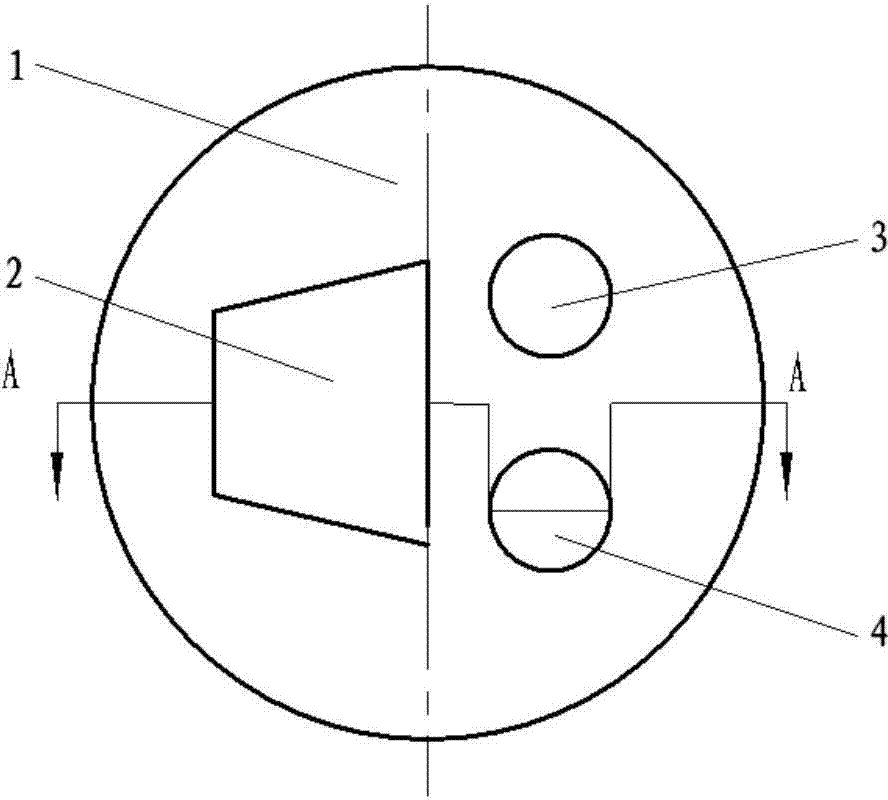

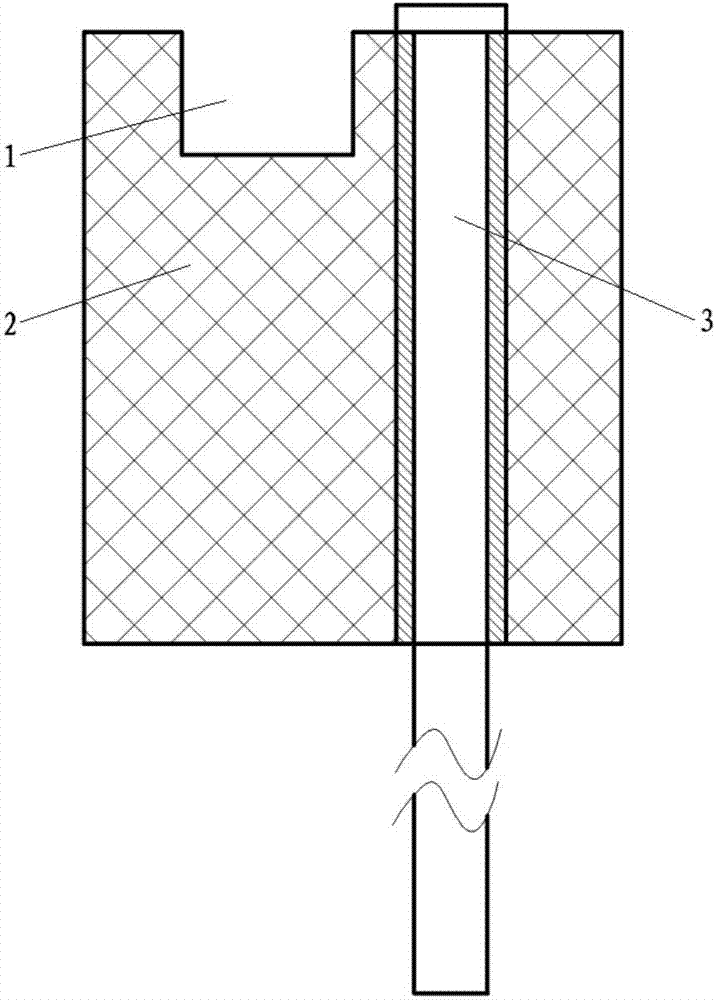

[0019] combine Figure 1-3 According to the specific size of the ceramic electrode plug, the processing mold is designed, wherein the diameter of the ceramic electrode plug is 2.0-2.2mm, the height is 1.0-1.2mm, the short side length of the trapezoidal groove is 0.55-0.6mm, and the long side length is 0.6-0.7mm mm, the side height is 0.5~0.6mm, the groove depth is 0.6mm, the long side is located on or near the symmetrical center line of the electrode plug, the diameter of the two legs is 0.3~0.4mm, the pole distance is 0.6~0.8mm, and the diameter of the head is 0.45mm, the distance between the center line of the two legs and the center of the electrode plug is 0.3~0.5mm.

[0020] The grouting method is used to add an appropriate amount of water and a small amount of electrolyte to the ceramic powder to form a relatively stable slurry, inject the slurry into the metal mold, remove the water, and achieve molding. A good slurry has good fluidity, sufficiently small viscosity, go...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com