Lithium battery end structure and manufacturing method

An end structure, lithium battery technology, applied in the direction of electrolyte battery manufacturing, lithium battery, battery pack components, etc., can solve the problems of occupying lithium battery, electrolyte leakage, complexity, etc., to improve the structural connection strength and ensure compactness , use the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

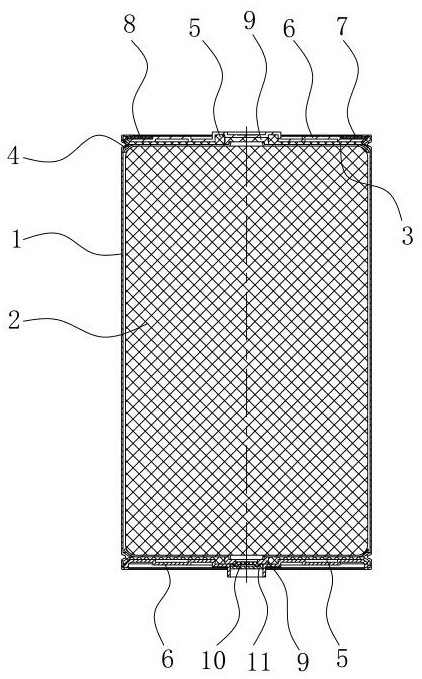

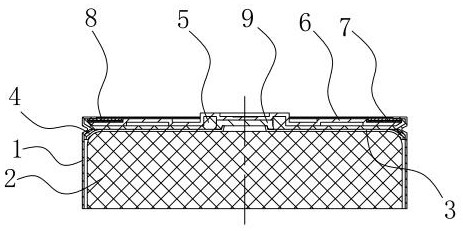

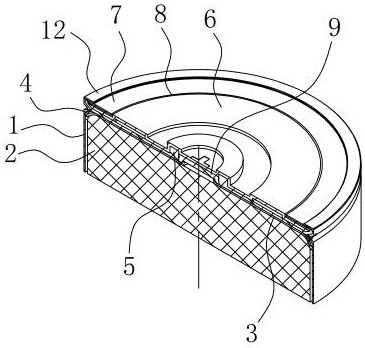

[0039] Such as Figure 1~Figure 15 As shown, 1. Shell, 2. Cell, 3. Current collector, 31. Liquid injection hole, 32. Convex ring, 4. Insulation ring, 5. Seal ring, 6. Cap, 61. Blind hole, 62. Cover hole, 63. Inner crimping, 7. Conductive support ring, 8. Ring sealing ring, 9. Collecting cap, 91. Cone seal, 92. Collecting hole, 10. Explosion-proof sealing cover, 11. Negative cap, 12. Outer crimping, 13. Rolling groove.

[0040] A lithium battery terminal structure and manufacturing method, such as figure 1 As shown, it has two structural forms, the first structural form is as figure 2 , image 3 As shown, this structural form can only be used as the positive end, and the second structural form is as image 3 , Figure 4 As shown, this structural form can be used as both the negative terminal and the positive terminal. Therefore, in a lithium batt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com