Pre-buried shear key connector box for precast facade panel and machining method of pre-buried shear key connector box

A shear key and external wall panel technology, which is applied to building reinforcements, structural elements, building components, etc., can solve the problems of inability to perform external wall decoration of external leaf panels, reduced strength of steel bars, and complicated operation process. , to achieve the effect of convenient standardized mass production, easy production and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

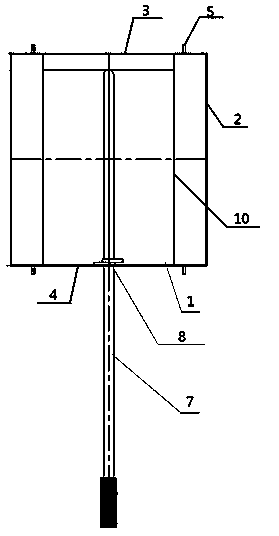

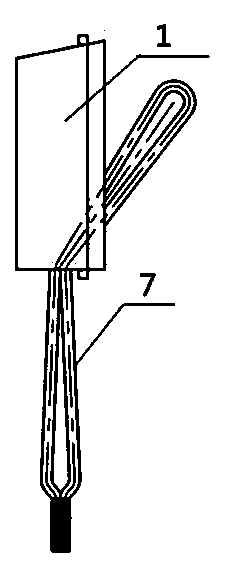

[0024] see figure 1 — Figure 5 , the pre-embedded shear keyway box of the prefabricated exterior wall panel of the present invention comprises a box body surrounded by an upper top plate, a lower bottom plate provided with a puncture hole, and three side panels, and a Connecting cables, the side of the box body without a side plate is the open side.

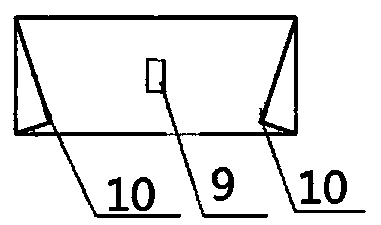

[0025] The upper top plate of the box body is set to be inclined towards the outside of the box body; the two side plates and the lower bottom plate adjacent to the open side of the box body are set to be inclined towards the inside of the box body.

[0026] At least one side plate and / or the inner side of the lower bottom plate of the box body is provided with a protrusion.

[0027] The inner side of at least one side plate of the box body is provided with a rib parallel to the open side.

[0028] In the box body, the upper and lower edges of the side plates adjacent to the open side are provided with connecting ear pieces, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com