Wedge shape pore plate flow measurement device with whole tungsten carbide material

A flow measuring device and wedge-shaped hole technology, applied in the field of integral tungsten carbide material wedge-shaped orifice plate flow measuring device, can solve the problems of poor assembly process, unable to be tightened again, wedge-shaped block damage to downstream equipment, etc., to ensure accuracy and consistency , The reliability of use is convenient, and the effect of ensuring the accuracy of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

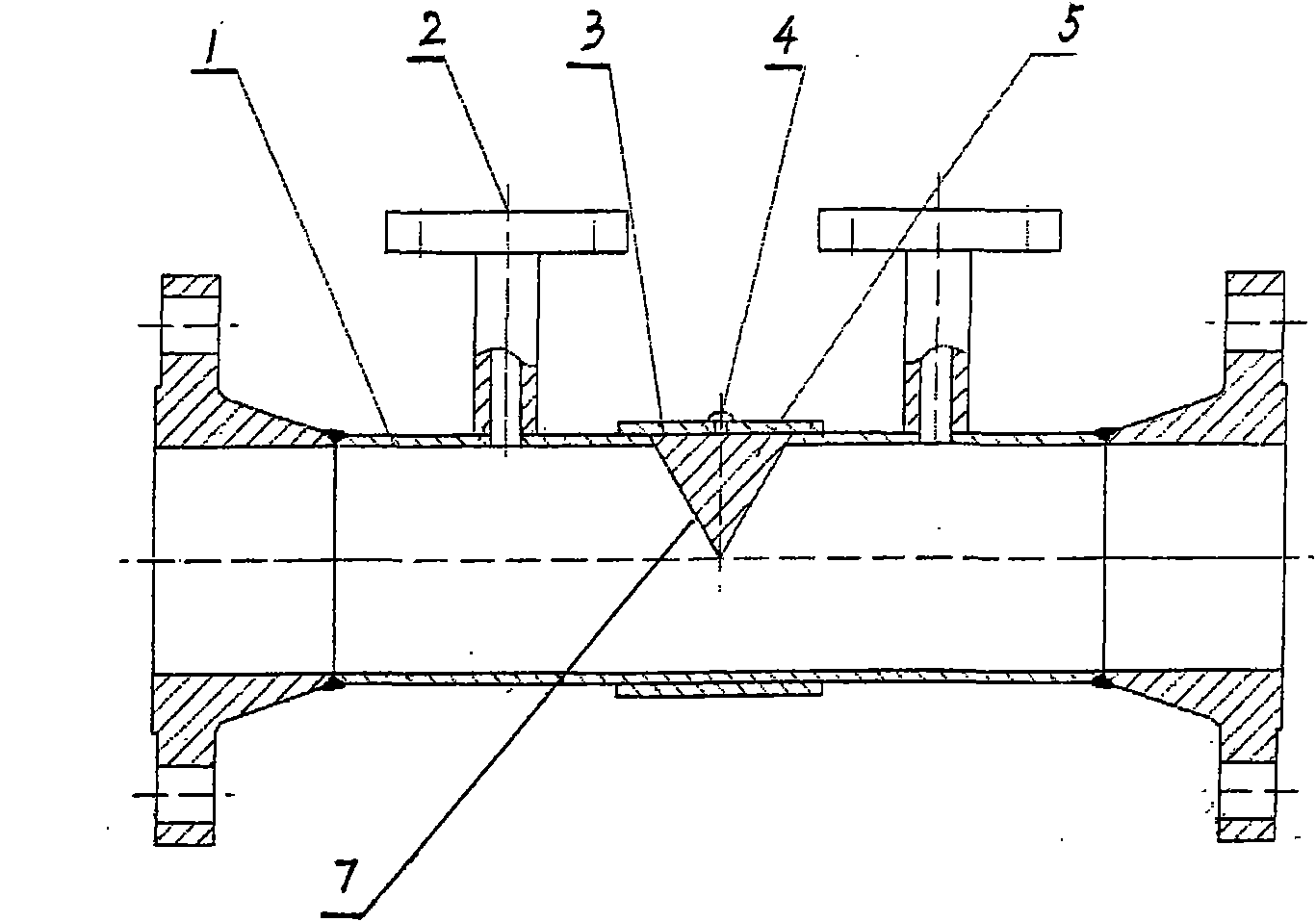

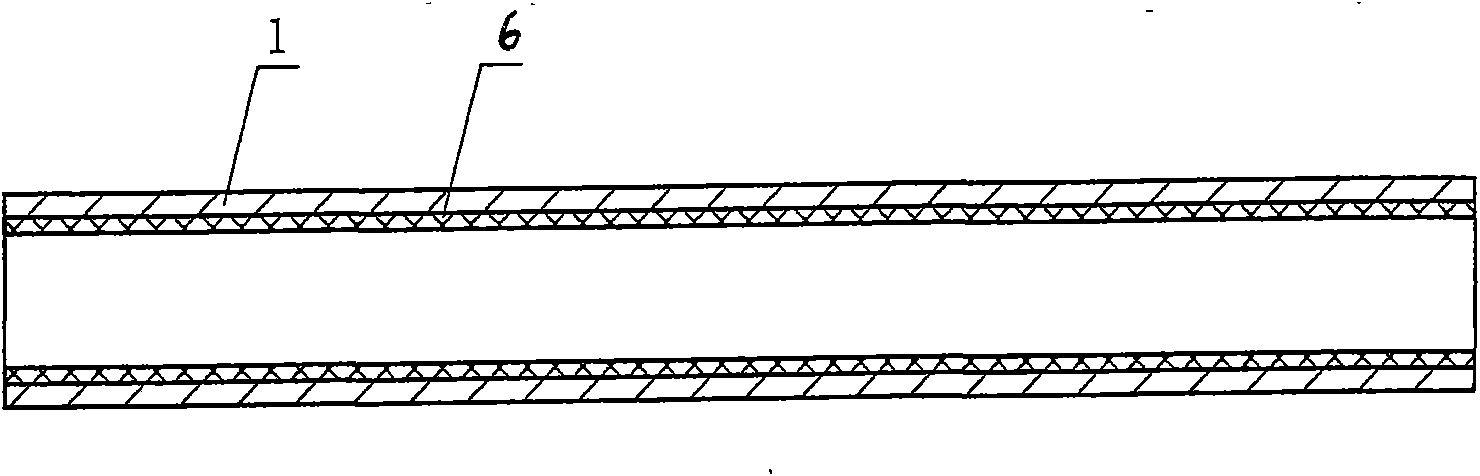

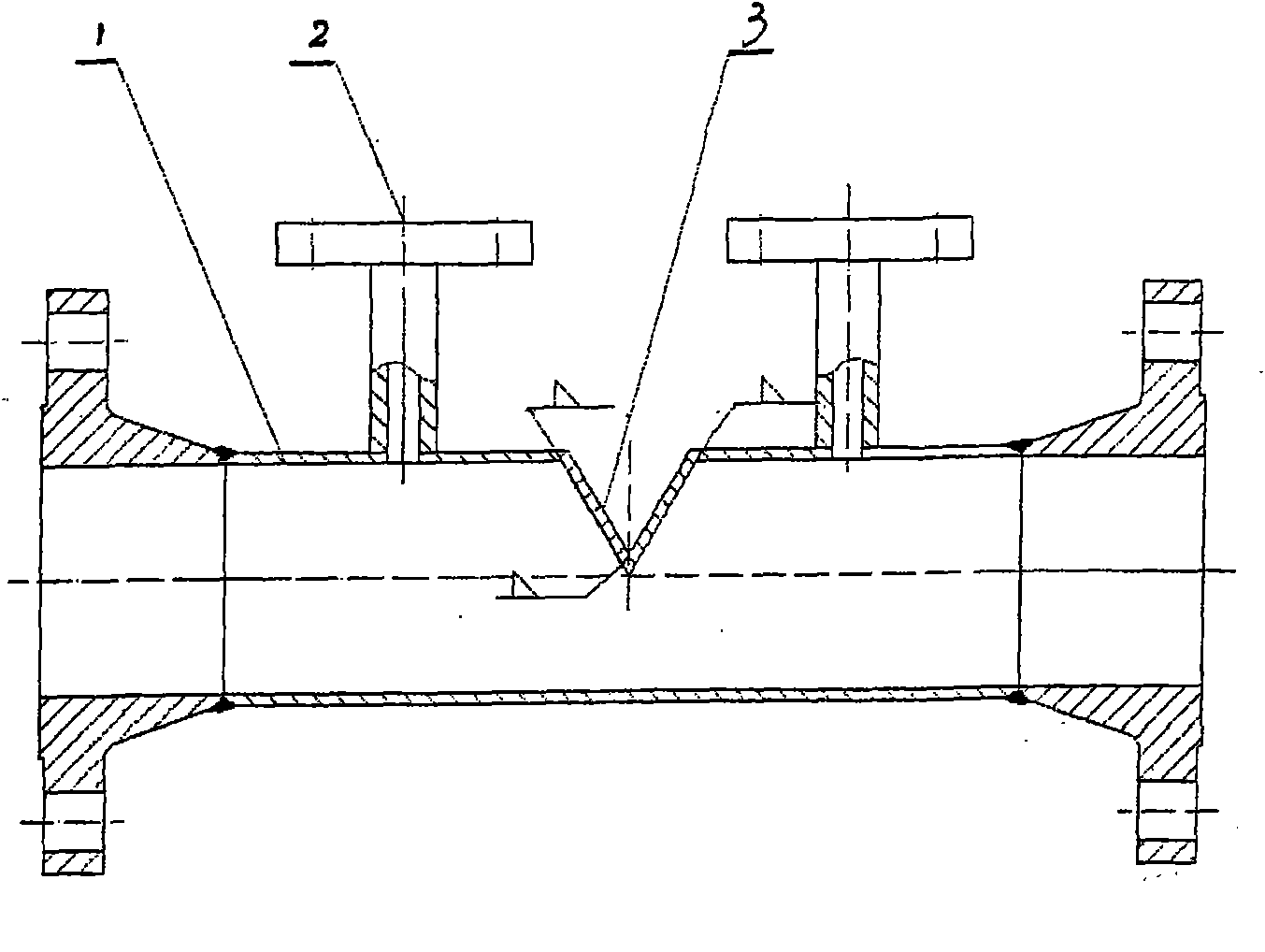

[0026] A wedge-shaped orifice flow measuring device made of integral tungsten carbide is composed of a measuring tube 1 , a pressure-taking component 2 and a wedge-shaped orifice 5 . Wherein: the shape of the wedge-shaped orifice plate is a wedge-shaped block with a triangular cross-section and a smooth top corner facing downward. The wedge-shaped orifice plate is formed by grinding after integral sintering of tungsten carbide material; the tube wall of the measuring tube is sprayed with tungsten carbide layer 6, and a wedge opening 7 matching the shape of the wedge-shaped orifice plate is opened on the measuring tube. Tightening bolt 4 compresses the wedge-shaped orifice plate in the wedge mouth. A sleeve 3 is sleeved on the wedge-shaped orifice plate, and the sleeve is used to assist the fixing and sealing of the wedge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com