Railway vehicle and end wall thereof

An end wall and door technology, applied in the field of rail transit, can solve the problems of low commercialization, inability to effectively suppress the vibration of the side pull door, weak connection strength between the end wall and the roof, etc., to enhance the end sealing performance and cushion the longitudinal direction Vibration, reducing the effect of lateral channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0030] Without loss of generality, in this embodiment, the end wall shown in the figure is used as the main body of description, and the improvement scheme for the end wall is described in detail. It should be understood that the size ratio relationship of the end wall is not the core invention point of the application, and does not constitute a substantial limitation on the technical solution claimed in the application.

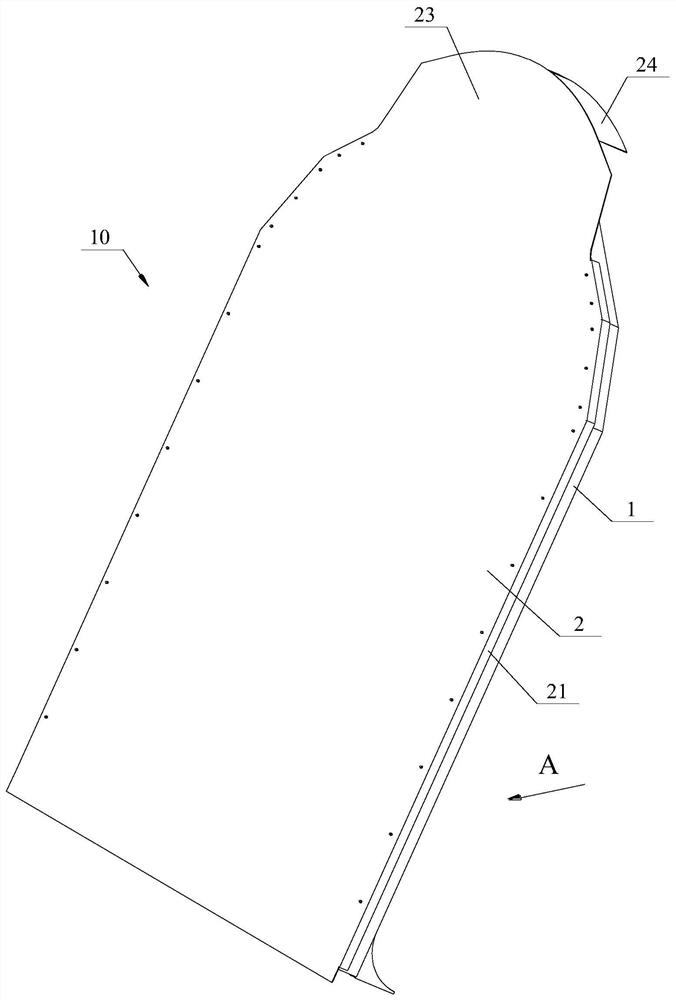

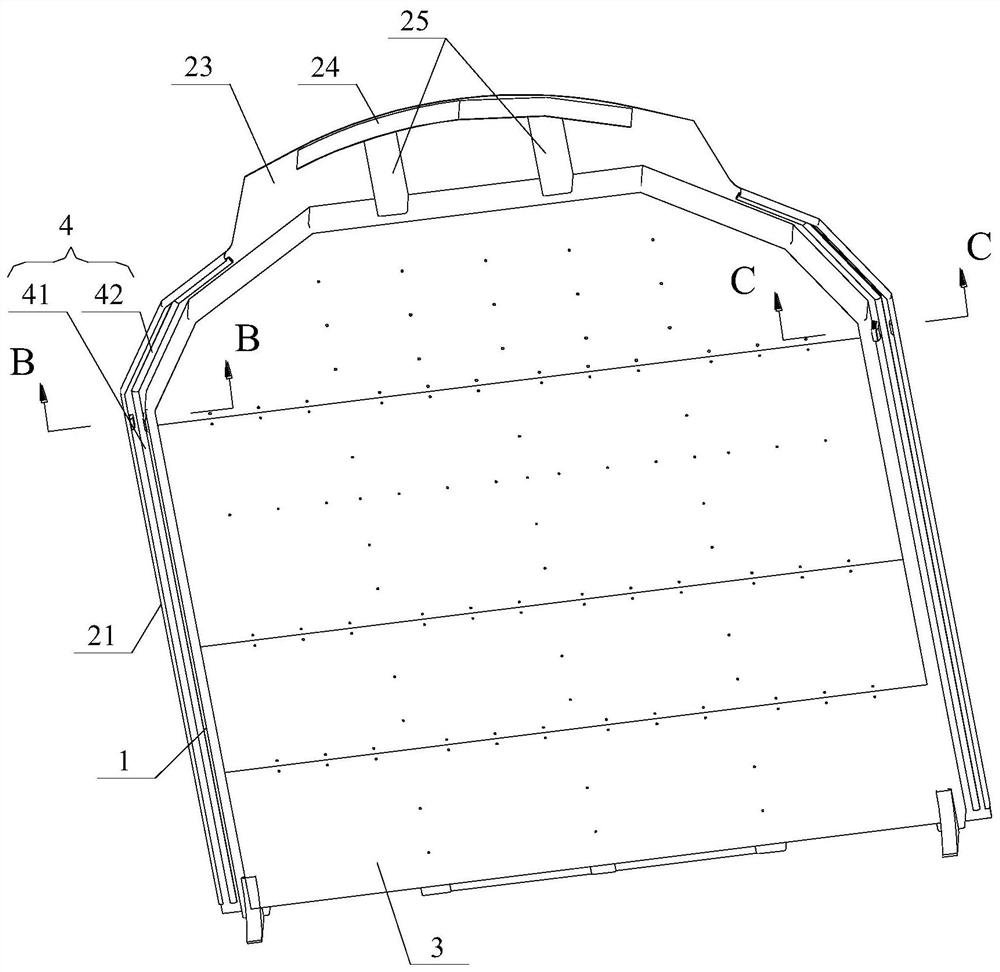

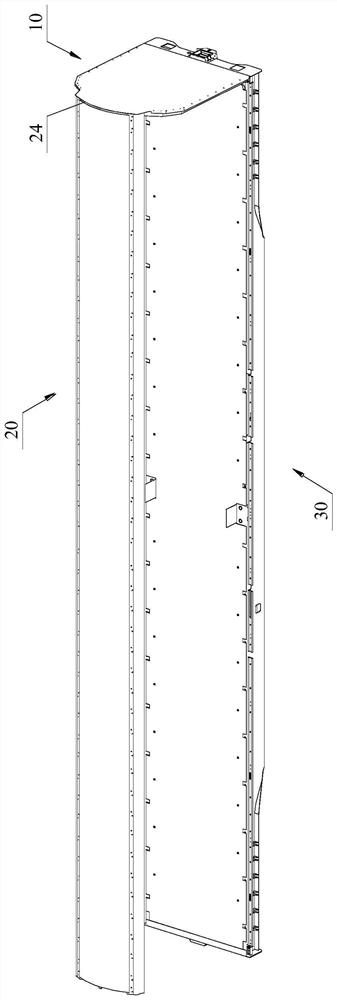

[0031] See figure 1 and figure 2 The schematic diagram of the overall structure of the end wall in this embodiment is shown, wherein, figure 1 Shown is from the exterior of the vehicle body; figure 2 shown by figure 1 It is formed from the perspective inside the car body shown in A.

[0032] This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com