An h∞ Robust Control Method for Mode Switching in Hybrid Power-split Hybrid Powertrain

A hybrid power system and composite power splitting technology, applied in hybrid vehicles, control devices, motor vehicles, etc., to reduce sliding friction work, ensure startability, and suppress errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

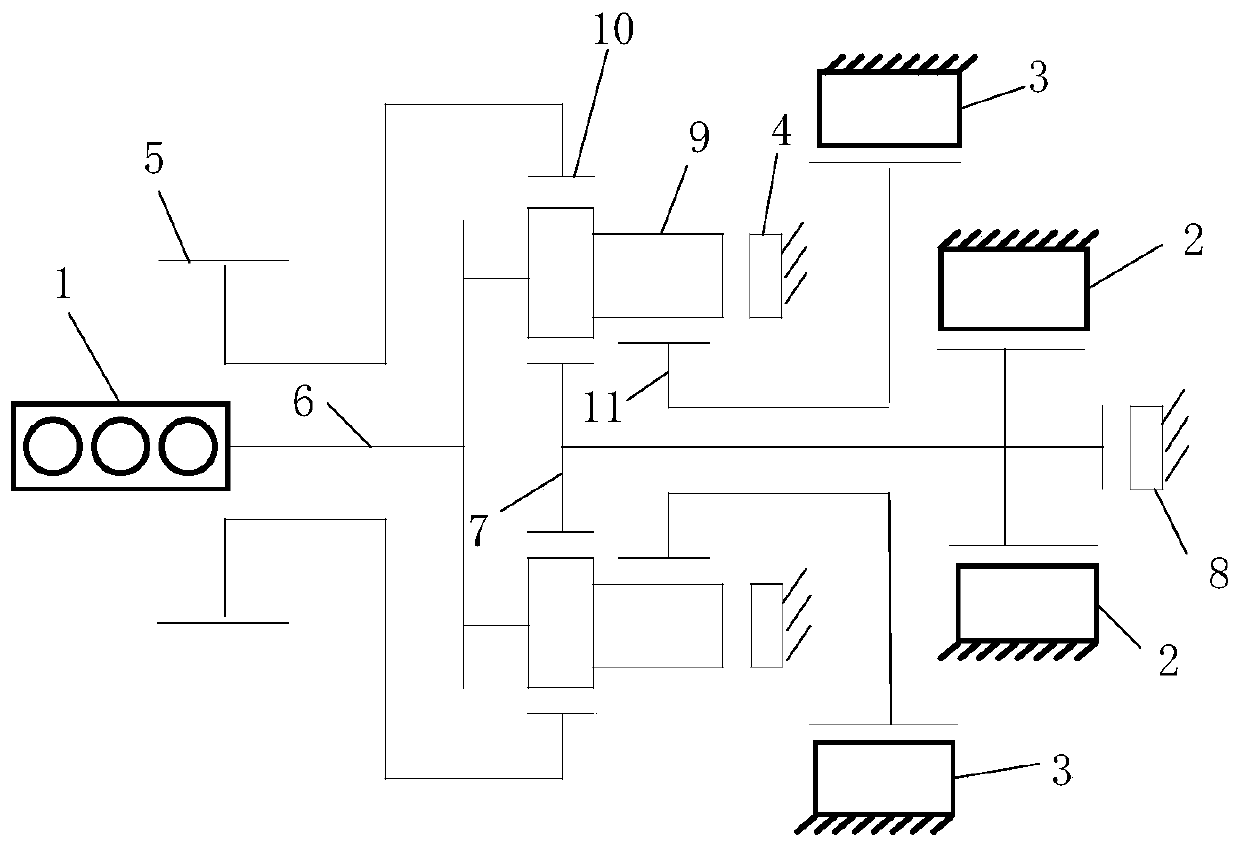

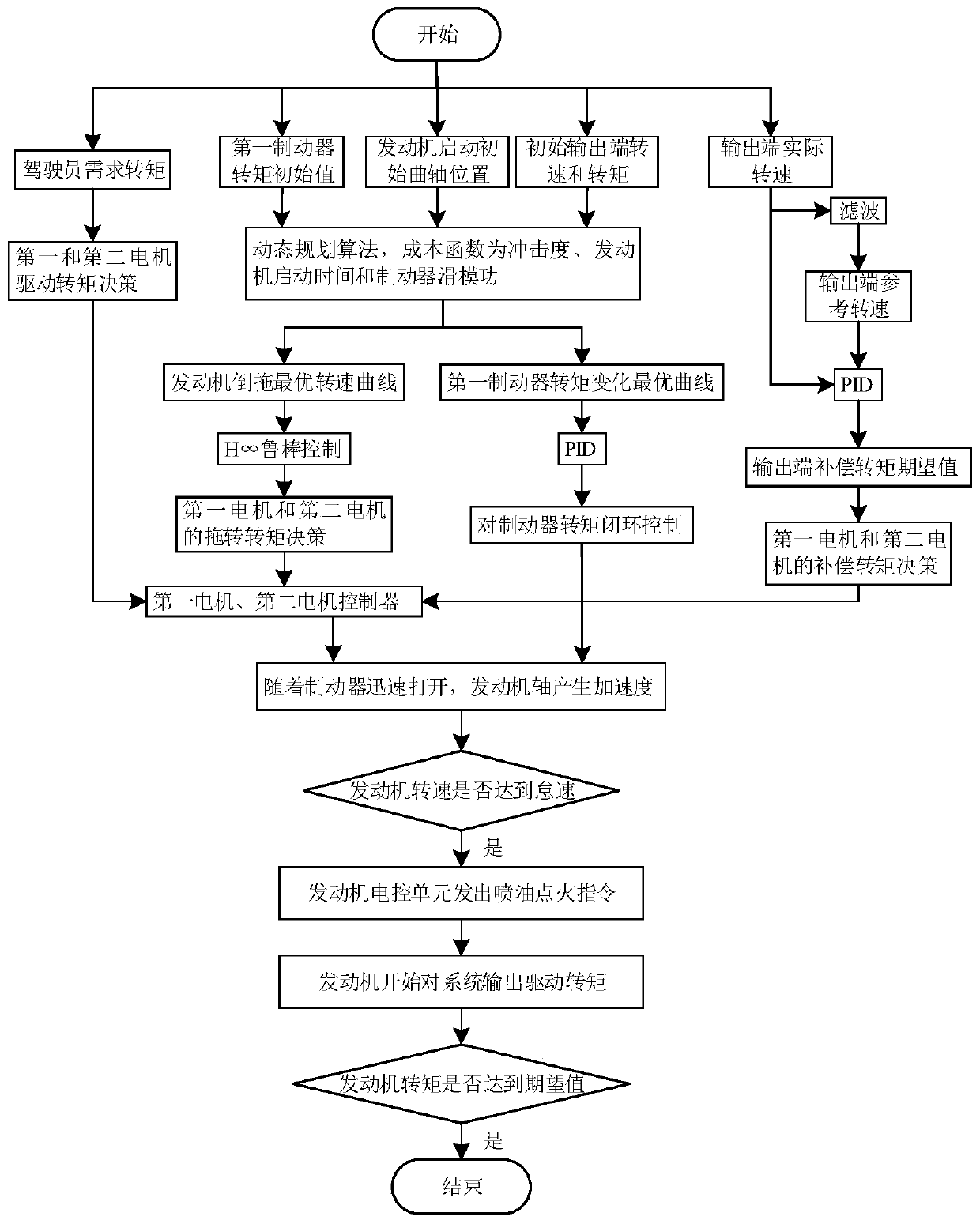

[0036] This application proposes an H∞ robust control method for mode switching of a compound power-split hybrid power system. Such as figure 1 As shown, the compound power-split hybrid power system includes a dual-planetary power coupling device, a motor controller, a first motor 2, a second motor 3, an engine 1, a first brake 4 and a second brake 8, and the first brake 4 and the second brake The two brakes are respectively connected to the planet carrier 6 and the front sun gear 7, and the first motor 2 and the second motor 3 are respectively connected to the front sun gear 7 and the rear sun gear 11. The function of the second brake is to lock the first motor 2 at a higher speed to prevent electric power from flowing back. The system can realize multiple modes such as pure electric mode driven by the second electric motor 3 alone, power split hybrid mode, and the like.

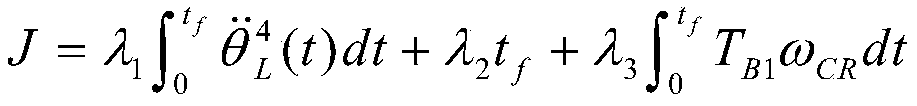

[0037] This method is aimed at the switching process from the pure electric mode driven by the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com