A three-way multi-stage energy-absorbing device for rail vehicles

A rail vehicle and energy-absorbing device technology, which is applied in the direction of railway vehicle wheel guards/buffers, transportation and packaging, railway car body parts, etc., can solve problems such as small energy absorption capacity, deformation instability, and reduced resistance , to achieve the effect of large energy absorption capacity, compact structure and small impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

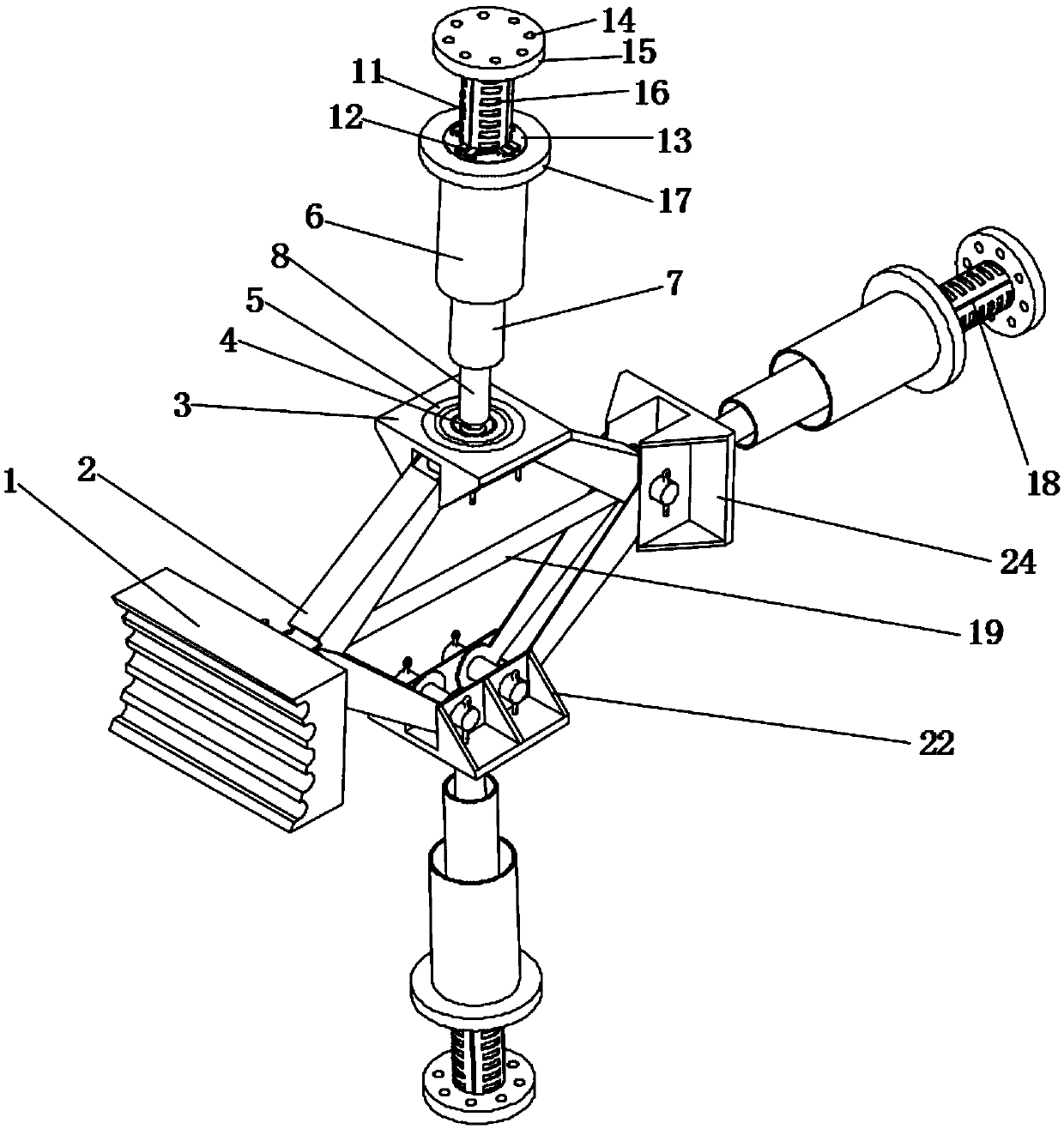

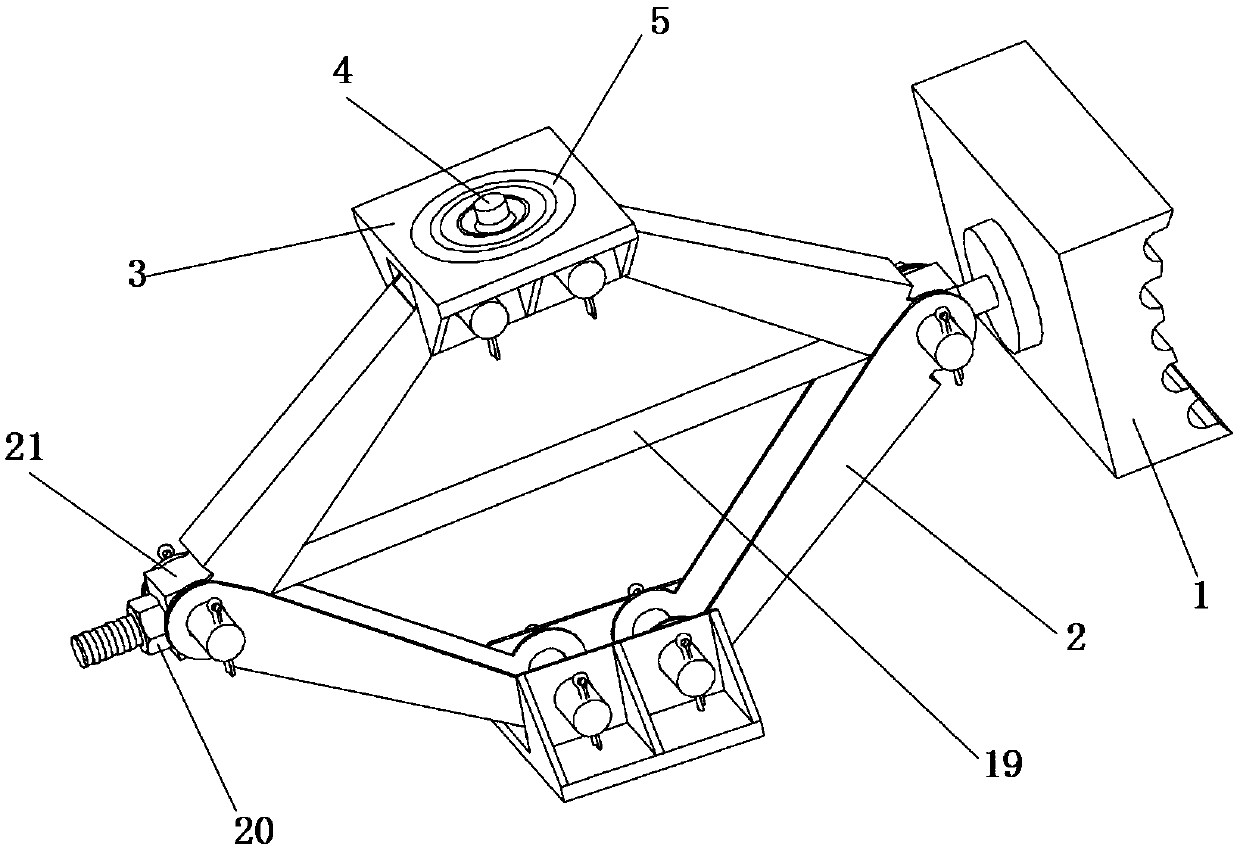

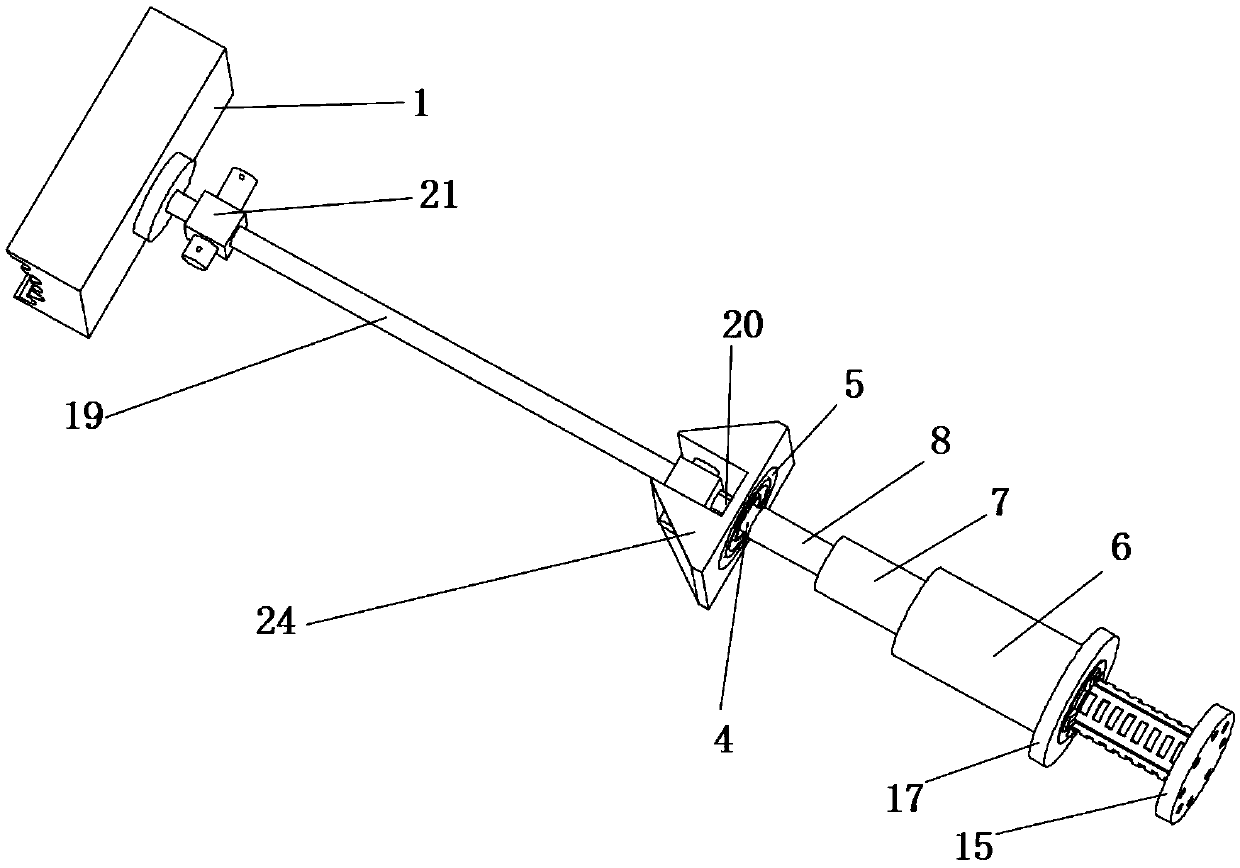

[0029] Such as figure 1 As shown, a three-way multi-stage energy-absorbing device for a rail vehicle includes an anti-climber 1, a bracket 2, an energy-absorbing pipe 8 and a cutting shaft 9; the anti-climber 1 is connected to one end of a screw 19; the other end of the screw 19 passes through The hole and the induction ring 23 of the boss 21 in the single-hole top block 24 are limited by the nut 20; the bracket 2 is hinged by a bolt to form a parallelogram structure; the double-hole top block 3 or the single-hole top block 24 is connected to the bracket 2 and the first energy-absorbing tube 8, the two sides of the top block are provided with reinforcing ribs 22, the back end of the double-hole top block 3 is provided with a rolling groove 5 and the induction platform 4, and the back end of the single-hole top block 24 is provided with an induction ring 23; the energy-absorbing tube One end of 8 is interference fit with the induction table 4; one end of the energy-absorbing tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com