A light-weight gondola car for ore transportation

A lightweight, ore technology, applied in the fields of railway transportation equipment and mechanical design and manufacturing, it can solve the problems of unsatisfactory stress state of the overall structure of the vehicle, inability to fully utilize railway transportation equipment, and different application conditions of railway freight cars, etc. The number of main joints, the realization of lightweight design, the effect of improving the strength reserve

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. However, it should not be construed that the scope of the above-mentioned subject matter of the present invention is limited to the following examples.

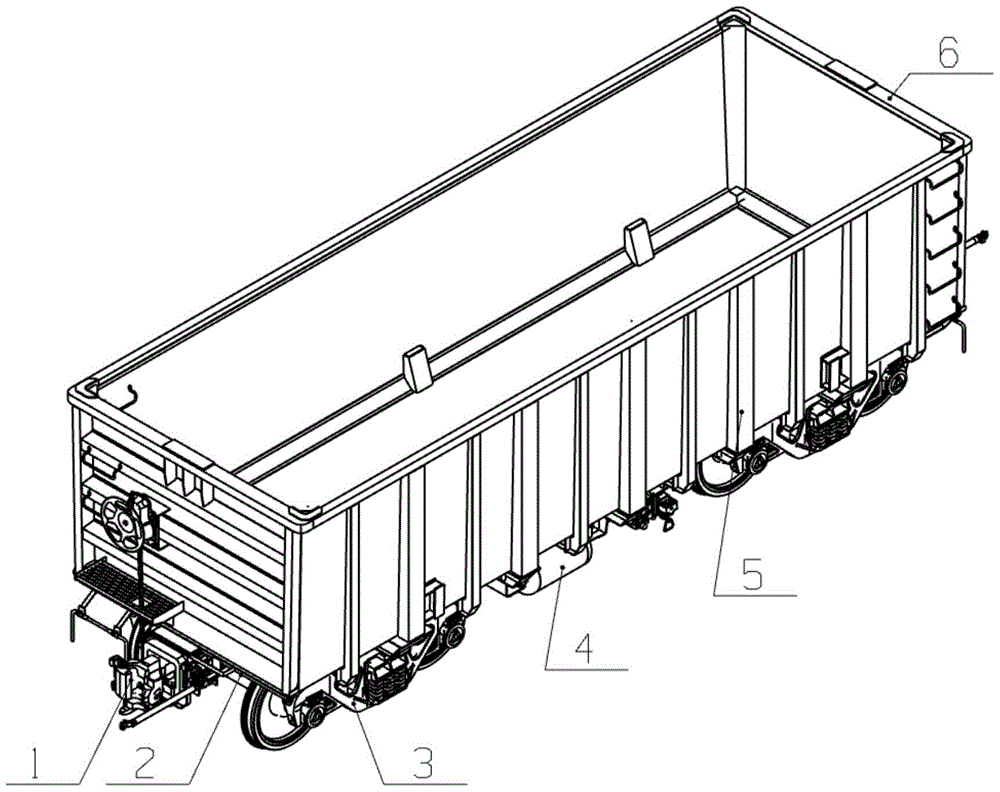

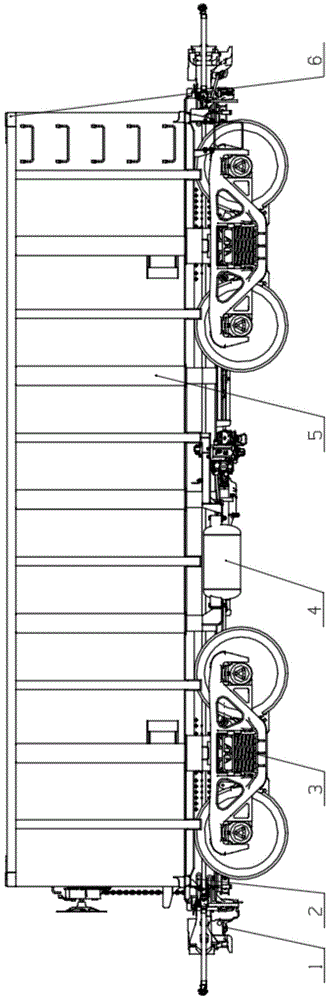

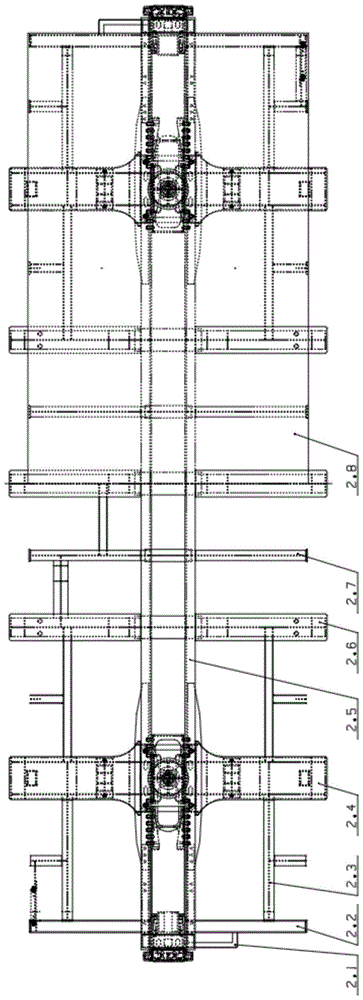

[0036] combine Figure 1 to Figure 13 , the present invention provides a lightweight gondola car for ore transportation, which includes a car body steel structure, a coupler buffer device 1, a bogie 3 and a braking device 4, and the car body steel structure includes an underframe 2, side walls 5 and The end wall 6 and the side wall 5 are vertically arranged on both sides of the underframe 2, and the end wall 6 is vertically arranged at the head and tail ends of the underframe 2. The front and rear ends of the special gondola car body are equipped with a coupler buffer device 1 and the end wall 6 Corner column 6.2 and corner anti-slag board 6.7 are provided at the connection with side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com