A light steel structure rectangular tube beam-column connection node

A light steel structure and connection node technology, applied in the field of steel structure manufacturing, can solve the problems of high labor intensity, low construction efficiency, troublesome installation, etc., achieve high structural connection strength, convenient installation and disassembly, and reduce welding work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, a detailed description will be given below in conjunction with the drawings and specific embodiments.

[0048] The present invention aims at the technical problems that the beam-column connections of the light steel structure rectangular pipes in the prior art are all welded and installed on-site, with high cost, troublesome installation, low construction efficiency, high labor intensity of workers and environmental protection, and provides a light steel structure rectangular pipe The beam-column connection node.

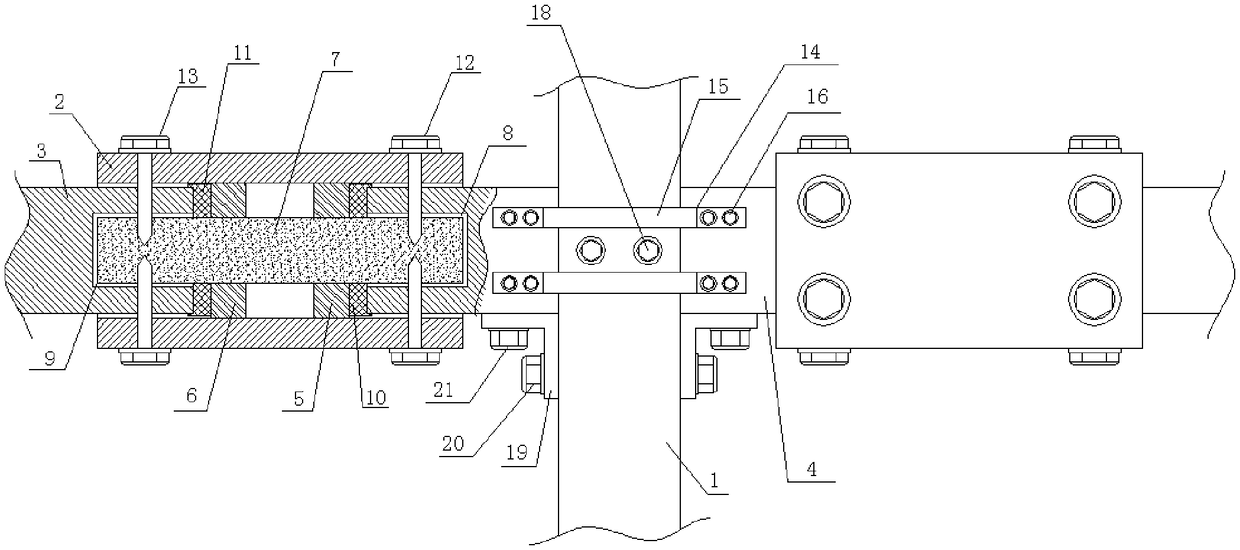

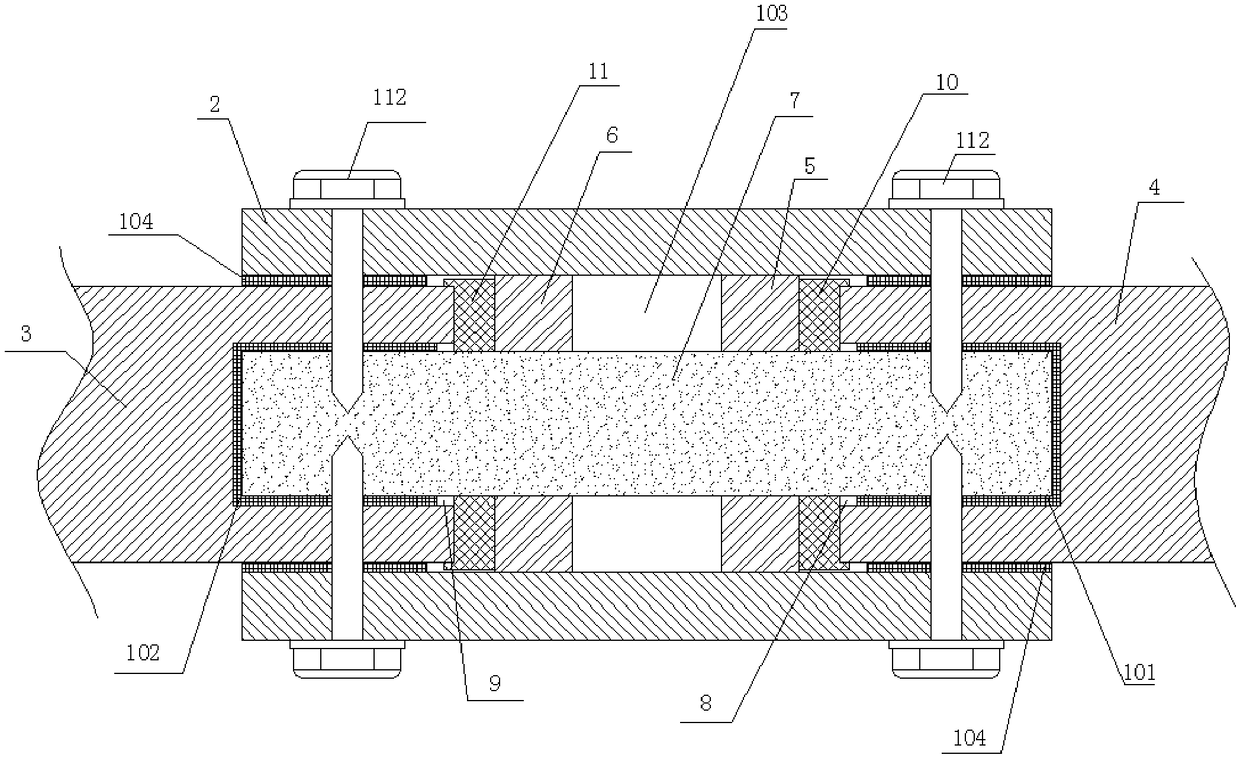

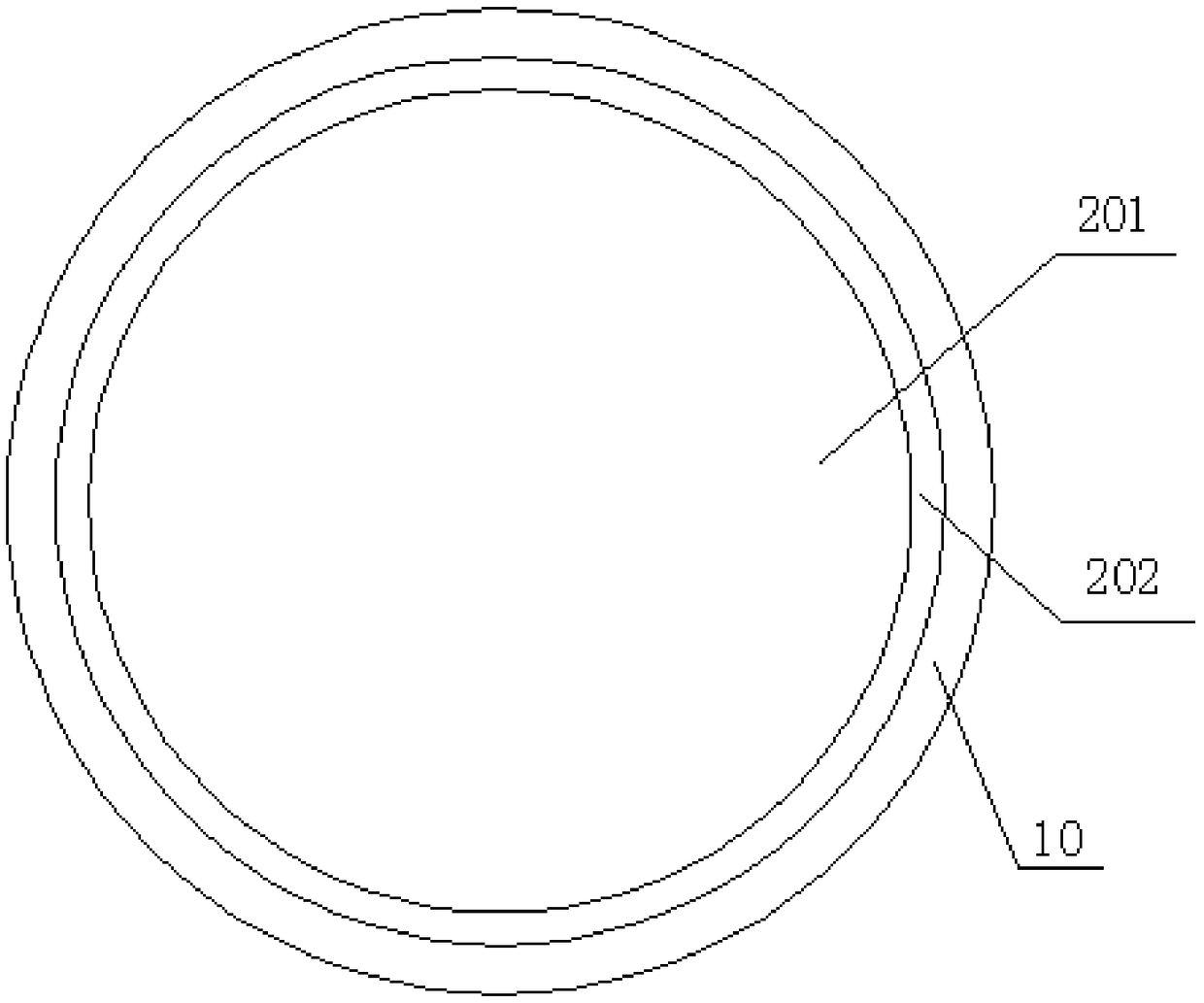

[0049] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides a light steel structure rectangular tube beam-column connection node, including a square tube column 1, two mounting sleeves 2 and two rectangular tube main beams 3, the square tube column 1 penetrates A rectangular tube cantilever beam 4 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com