Grouting device for steel shear structure assembling type building and construction method of grouting device

A grouting device and prefabricated technology, applied in the processing of building materials, construction, building components, etc., can solve the problems of reducing quality, affecting the beauty of the wall, labor and time and materials for the restoration of the wall, etc., to improve the strength and The effect of shear resistance and earthquake resistance, ensuring project quality and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail:

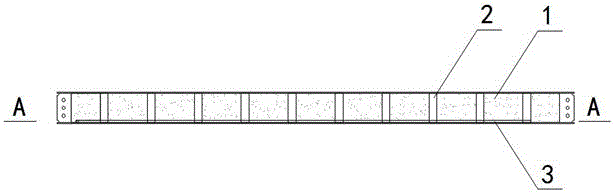

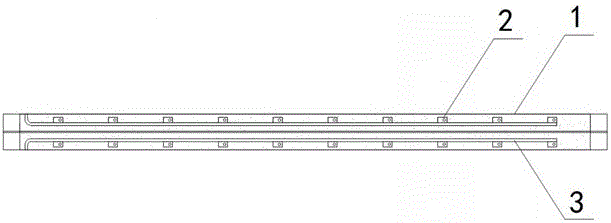

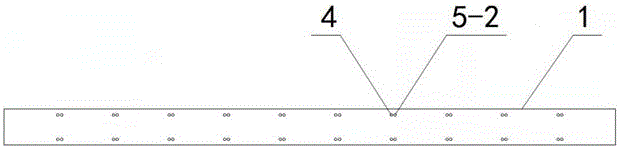

[0024] A grouting device for a prefabricated building with a steel shear structure, the structure of which is as follows Figure 1-4 As shown, it includes a grouting sleeve 2 arranged in the abdomen of the H steel beam 1, a grouting connecting pipe 3, an upper layer steel bar insertion hole 4 and a lower layer steel bar extension hole set on the upper flange of the H steel beam 1 5-2 and the lower reinforcement insertion hole 5-1 provided on the lower flange of the H steel beam 1, the upper reinforcement insertion hole 4, the lower reinforcement hole 5-2 and the lower reinforcement insertion hole 5-1 are all connected with the grouting Sleeve 2 is connected.

[0025] The grouting communication pipe 3 is fixedly arranged on the inner upper side of the lower flange plate of the H steel beam 1 , and the grouting sleeve 2 communicates with the grouting communication pipe 3 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com