Connecting structure for front face and back face of light midbus with body frame of light midbus

A technology for connection structures and minibuses, applied in the connection between superstructure subassemblies, superstructure, vehicle components, etc., can solve the problem of structural strength and connection accuracy that need to be improved, the accuracy of embedded steel is difficult to guarantee, and the manufacturing process Complicated problems, to achieve the effect of high connection structure strength, enhanced structural strength, and good waterproof and sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings.

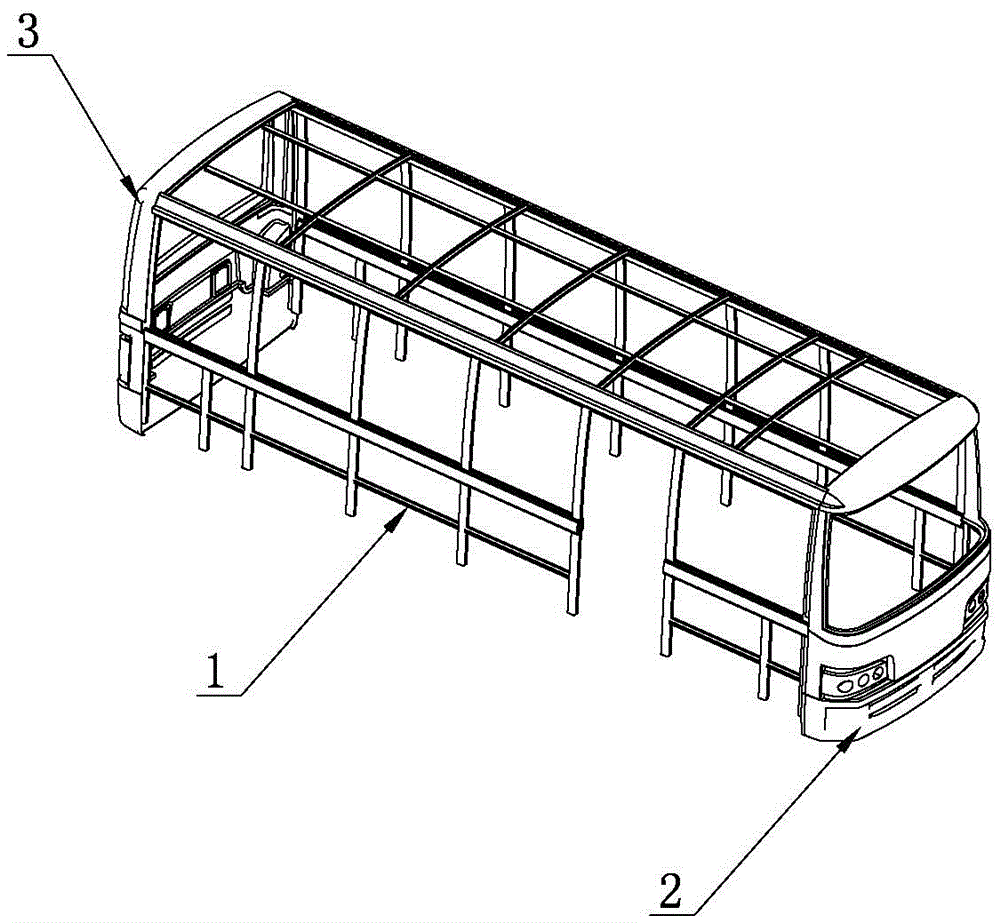

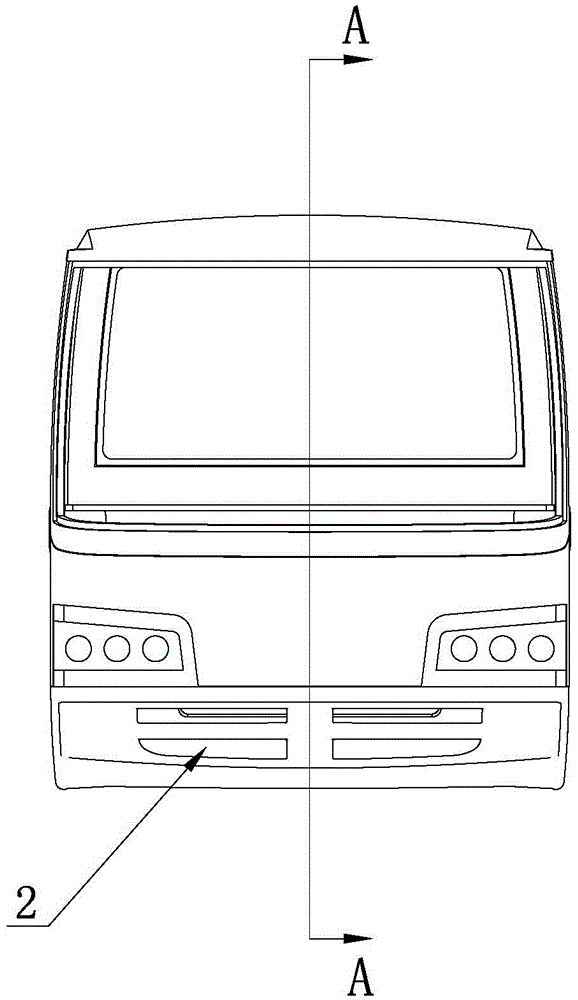

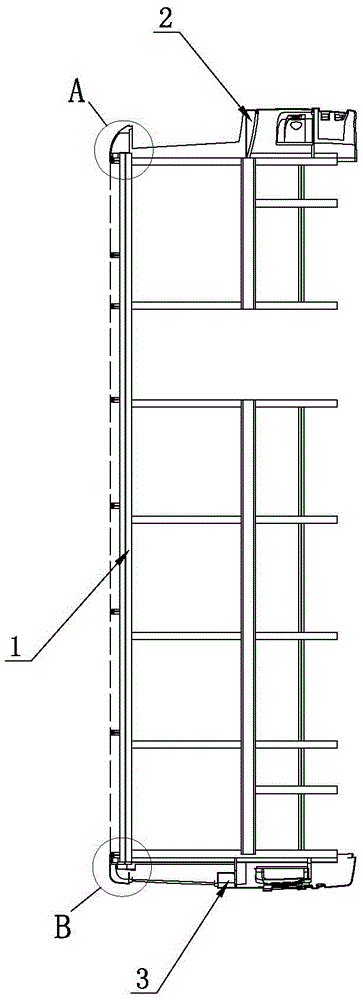

[0031] Such as Figure 1 to Figure 9 As shown, the connection structure between the front and rear faces of a light-weight minibus of the present invention and the body frame includes a car body connecting end frame 1, a car front face cover 2 and a car rear face cover 3, and the car body connecting end face frame 1 Formed by mortise and tenon joints of several sections of profile beams 5, the profile beams 5 at the front and rear ends of the body connecting end frame 1 are all provided with mounting slots 11, and the mounting slots 11 are connected with connection flashes 12. The cover part 2 and the automobile rear face cover part 3 are respectively fixedly installed on the front end and the rear end of the vehicle body connection end face frame 1 through the connection flash 12 . The connection flash 12 connected to the front and rear ends of the body connection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com