Energy-saving environment-friendly high-temperature hot air drying stove

A hot air drying furnace, energy-saving and environment-friendly technology, applied in drying, drying machines, heating devices, etc., can solve the problems of low heat energy utilization rate, difficult installation and maintenance, unsafe use, etc., to achieve long fire sealing time, installation Simple and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

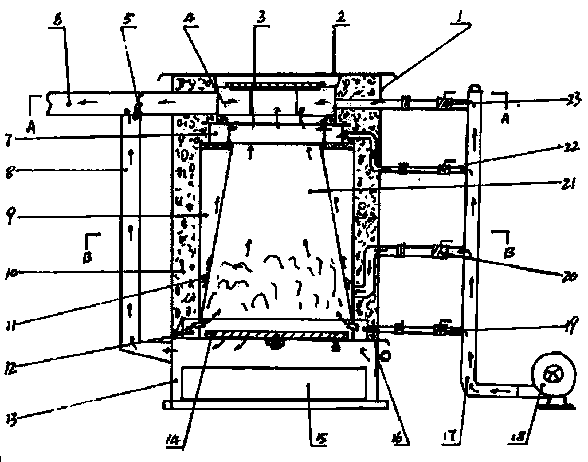

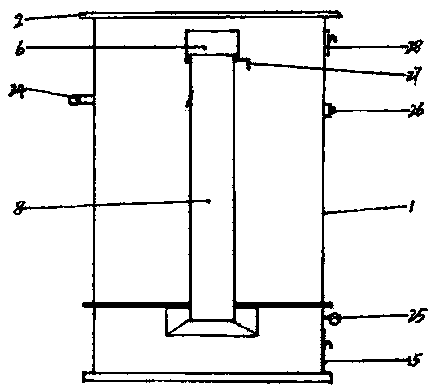

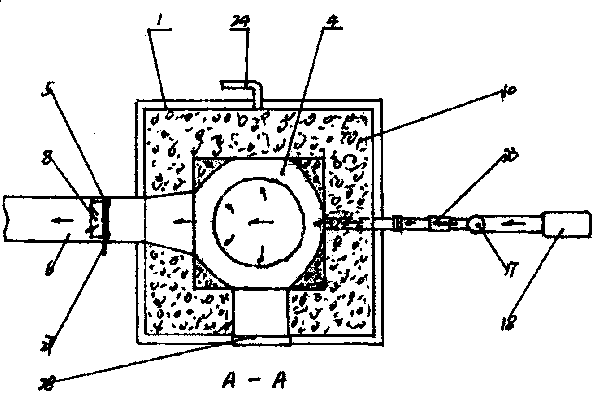

[0021] Below in conjunction with accompanying drawing, scheme of the present invention is described further:

[0022] Such as Figure 1-4 As shown, an energy-saving and environment-friendly high-temperature hot-air drying furnace mainly consists of a furnace body 1, a high-temperature hot-air cooling duct 6, an air inlet pipe 19 for a control valve of an oxygen-increasing combustion chamber at the bottom, an air inlet pipe 20 for a control valve of a high-temperature heating chamber, and a secondary Air inlet pipe 22 for control valve of oxygen-increasing oxidation chamber, air inlet pipe 23 for control valve of high-temperature energy storage chamber, outlet pipe 24 for high-temperature hot air, high-temperature energy storage chamber 4, secondary oxygen-increasing oxidation chamber 7, high-temperature heating chamber 9, bottom chamber Oxygen combustion chamber 12, furnace bottom air inlet ignition chamber 13 and medium pressure fan 18 are welded and assembled. There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com