A heat pump device for sludge drying

A technology of sludge drying and heat pump device, applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of unfavorable smooth operation of heat pump drying, unable to meet the requirements of sludge drying, low utilization rate of thermal efficiency, etc. To achieve the effect of compact structure, conducive to smooth operation, and improve the utilization rate of thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

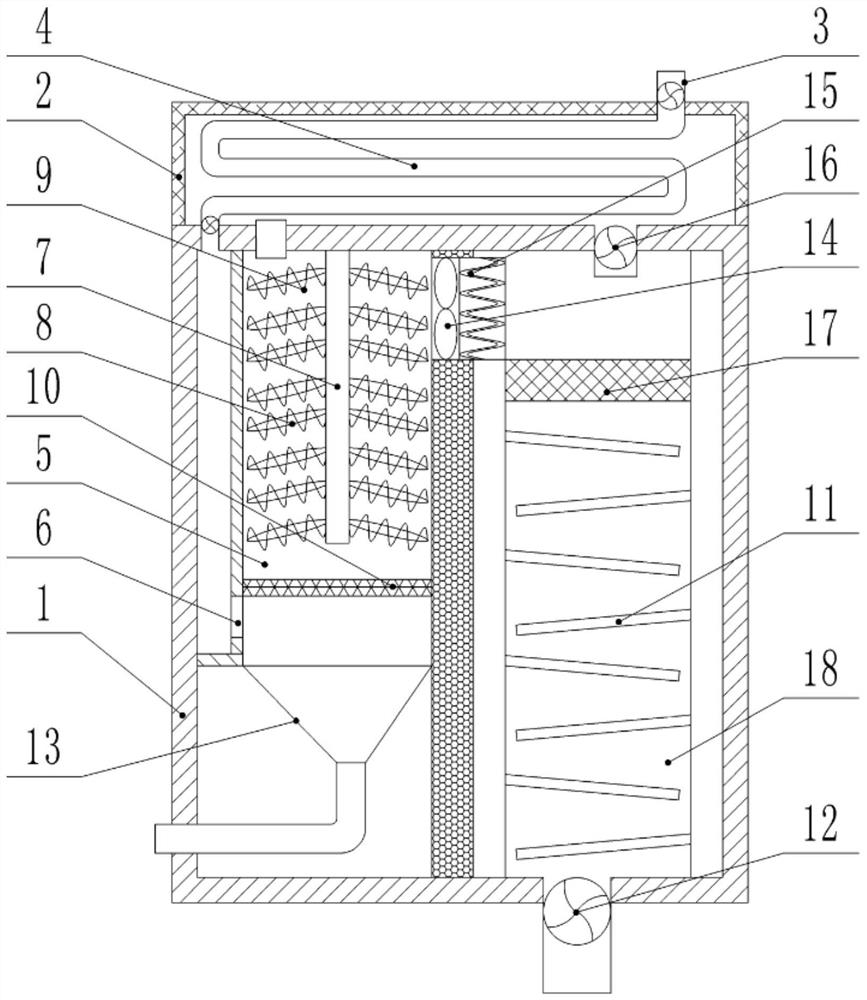

[0023]A heat pump device for sludge drying, comprising a shell 1, characterized in that a heat recovery box 2 is fixedly connected to the top of the shell 1, and an asbestos heat insulation sleeve is covered on the outer wall of the shell 1. The inner wall of the heat recovery box 2 is fitted with a thermal insulation board, and the heat recovery box 2 is arranged in a hollow cuboid structure, and the top side of the heat recovery box 2 is provided with a hot and humid air inlet pipe 3. The air outlet end of the hot and humid air inlet pipe 3 runs through the top of the heat recovery box 2 and is connected with a heat recovery pipe 4. The heat recovery pipe 4 is located inside the heat recovery box 2 and is arranged in a serpentine structure from top to bottom. The air outlet end of the heat recovery pipe 4 runs through the top of the housing 1 and communicates with the inside of the housing 1, and the hot and humid air inlet pipe 3 and the air outlet end of the heat recovery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com