Bottom stop assembly of zipper fast to take off

A technology for stoppers and zippers, applied in the field of bottom stop components of quick-release zippers, which can solve the problems that the pivoting part 12 has a relatively large force, is easy to break, and is easy to break, and achieves the effects of convenient exit, reliable positioning, and short stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

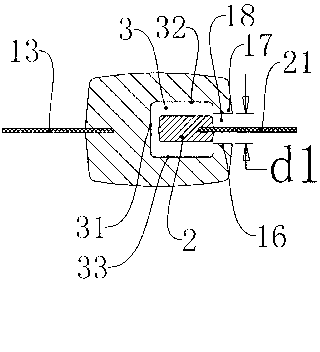

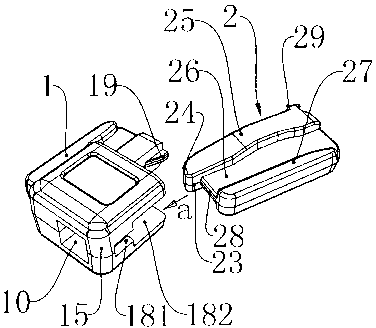

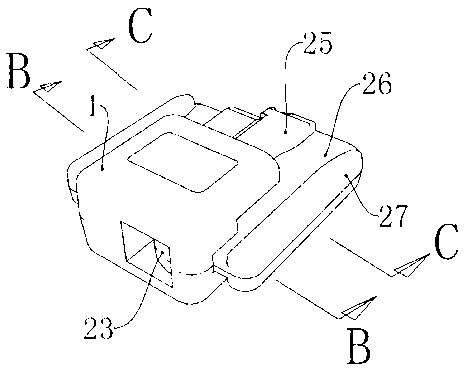

[0030] Such as figure 1 , figure 2As shown, a bottom stop assembly of a zipper includes a left stop 2 and a right stop 1, and the outer sides of the left stop 2 and the right stop 1 are respectively connected with a left zipper tape 21 and a right zipper tape 13, between which Connected by injection molding. The inner sides of the left zipper tape 21 and the right zipper tape 13 are respectively connected by injection molding to a left fastener element 22 and a right fastener element 12 which can be fastened to each other. When locking the zipper, first place the slider (not shown in the figure) on the tail end of the right stop 1, and then insert the left stop 2 into the right stop 1 after passing through the slider , then pull the slider to lock the left chain element 22 and the right chain tooth 12 together. It should be noted that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com