Ceiling wrapping corner and ceiling framework assembly

A roof and corner-wrapping technology, which is applied in the sub-assembly of the upper structure, transportation and packaging, and the upper structure, can solve the problems of weak overall load-bearing capacity and short life of the bus frame, and improve the strength and stability of the connection structure. The effect of improving the carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

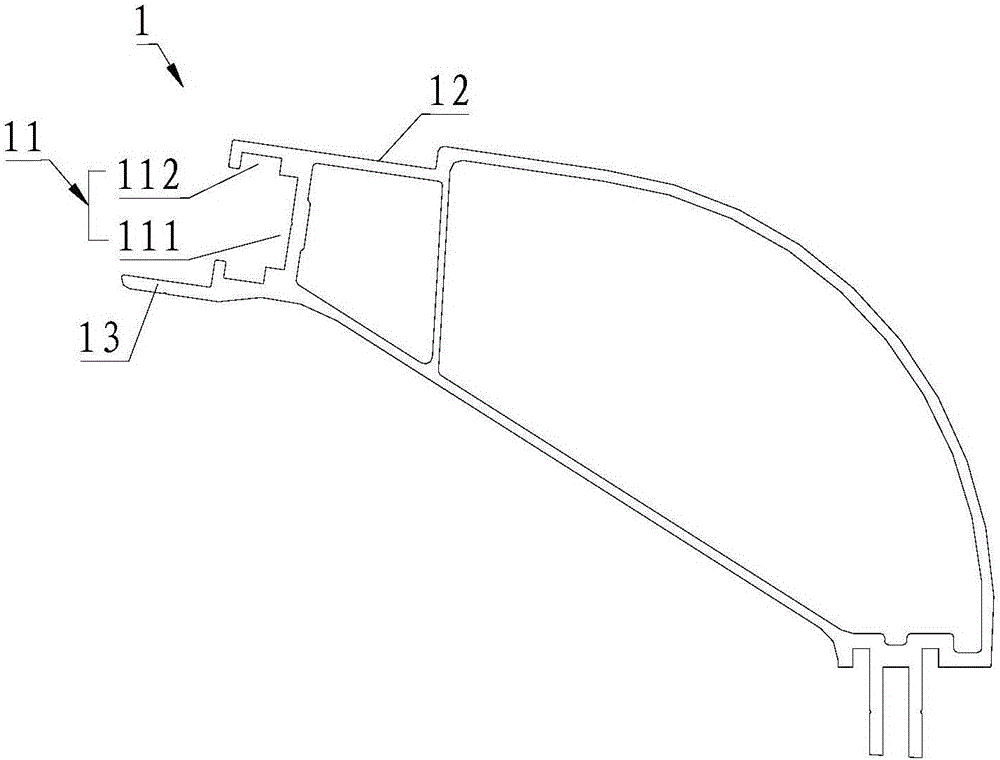

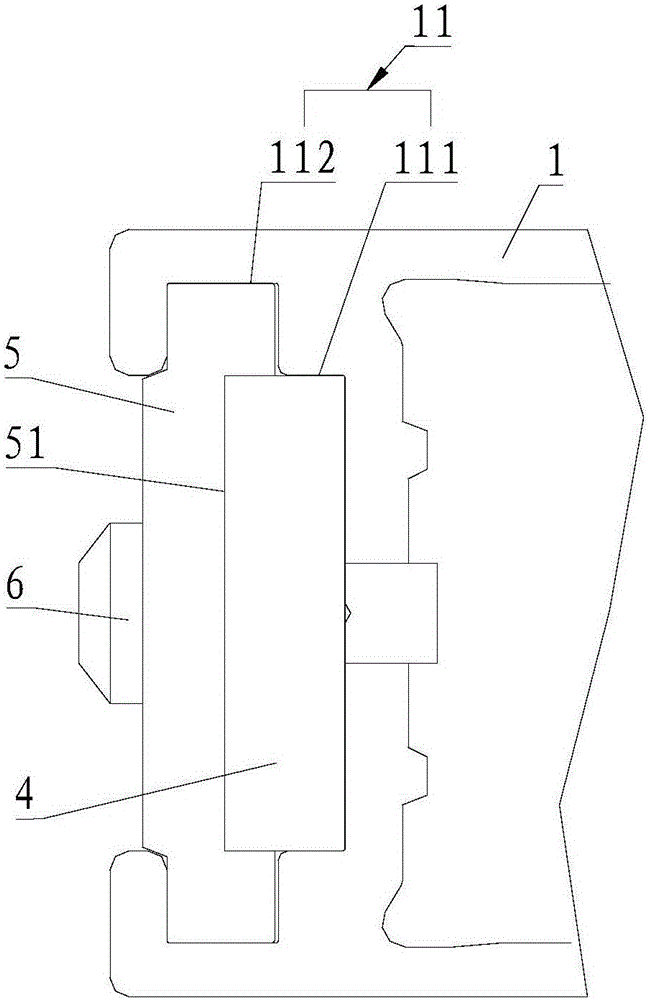

[0030] Please refer to Figure 1 to Figure 3 , Embodiment 1 of the present invention is:

[0031] A ceiling wrapping corner, comprising a ceiling wrapping corner 1, a riveting accommodation cavity 11 is provided on the inner surface of the upper end of the ceiling wrapping corner 1, and the riveting accommodation cavity 11 includes a first groove 111 and a second groove 112 , the second groove 112 is located on the two opposite inner side walls of the first groove 111, the first groove 111 is adapted to the shape of the external connecting piece 4, and the second groove 112 Adapt to the shape of the pressing block 5 of the peripheral; the connecting piece 4 and the pressing block 5 of the peripheral are connected to the ceiling wrapping corner 1 through a rivet 6; a ladder is provided on the outer surface of the upper end of the ceiling wrapping corner 1 Surface 12; a support plate 13 extending outward from the bottom of the upper inner end surface of the ceiling wrap angle 1...

Embodiment 2

[0043] Please refer to Figure 1 to Figure 6 , the second embodiment of the present invention is:

[0044] A ceiling frame assembly, comprising two ceiling corners 1 penetrating front and back, at least two beams 2 between the two ceiling corners 1, and at least two longitudinal beams 3 between adjacent beams 2 , the connecting piece 4 and the pressing block 5, the upper inner end surface of the ceiling wrap angle 1 is provided with a riveting accommodation cavity 11, and the riveting accommodation cavity 11 includes a first groove 111 and a second groove 112, the The second groove 112 is located on the two opposite inner sidewalls of the first groove 111, the first groove 111 is fit to the shape of the connector 4, the second groove 112 is compatible with the The shape of the compression block 5 is adapted; the riveting accommodation cavity 11 is also provided on the beam 2 and the longitudinal beam 3, and the compression block 5 and the connecting piece 4 are wrapped with t...

Embodiment 3

[0046] Please refer to Figure 1 to Figure 5 , Figure 7 , Embodiment three of the present invention is:

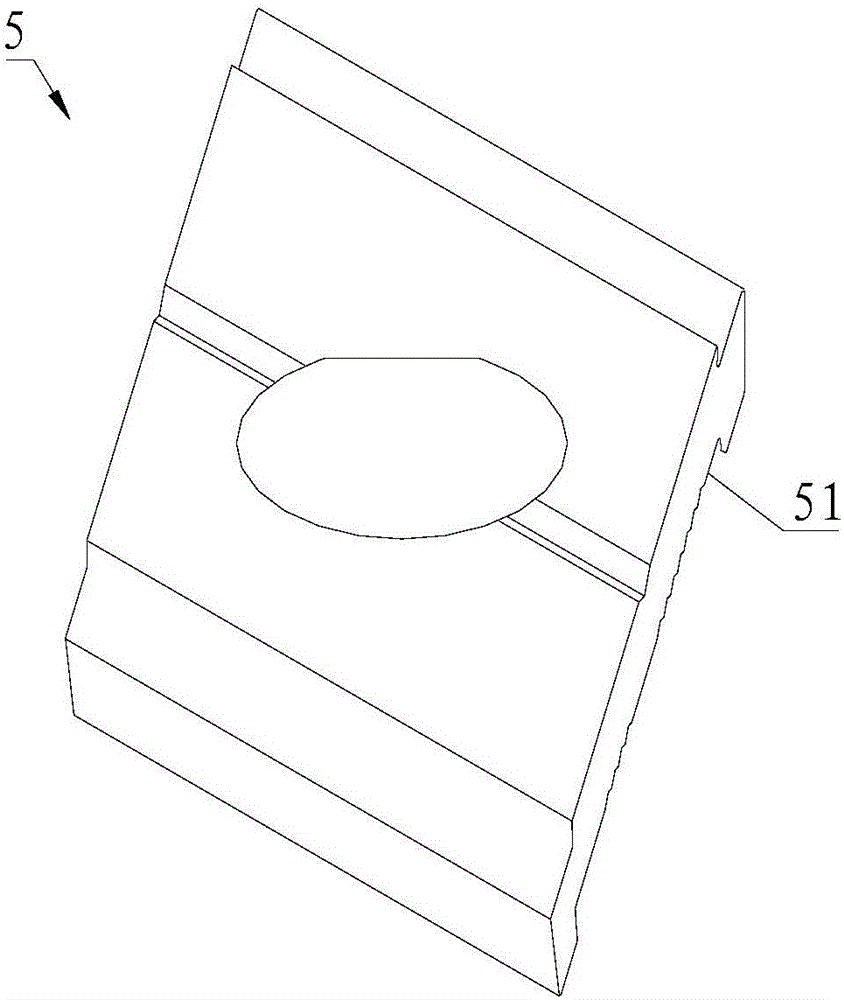

[0047] A ceiling frame assembly, which differs from Embodiment 2 in that: the cross-sectional shape of the connecting piece 4 is π-shaped, and the ceiling wrap angle 1 is connected to the beam 2 through a connecting piece 4, and the beam 2 It is connected with the longitudinal beam 3 through a connecting piece 4; the bottom of the pressing block 5 is provided with a third groove 51, and the width of the third groove 51 is adapted to the width of the connecting piece 4 .

[0048] The ceiling angle 1, the beam 2, and the longitudinal beam 3 are all aluminum profiles, which have the advantages of convenient processing, strong anti-corrosion ability, and light weight.

[0049] To sum up, in the roof wrapping angle and ceiling frame assembly provided by the present invention, the ceiling wrapping angle 1, the beam 2, and the longitudinal beam 3 are all provided with a rivet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com