Non-woven fabric with stable structure and preparation method thereof

A non-woven fabric and fixed-form technology, applied in the field of structurally stable non-woven fabric and its preparation, can solve the problems of low structural strength and stability, achieve structural stability, increase bonding area, and improve structural strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

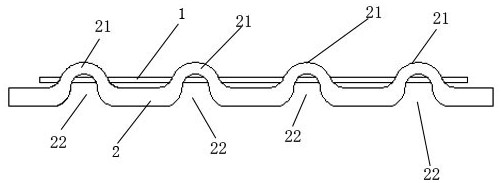

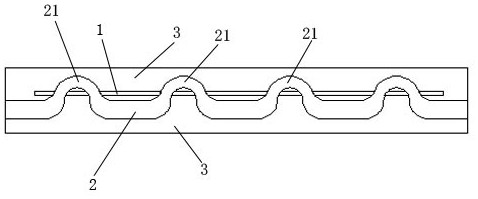

[0024] Such as figure 1 with 2 As shown, a structurally stable nonwoven fabric includes a nonwoven fabric core layer 2, a skeleton twisted fiber filament 1, and a surface coating 3; Protruding strips 21; the plurality of connecting raised strips 21 are evenly distributed from left to right; the plurality of connecting raised strips 21 are arranged in parallel; the lower sides of the connecting raised strips 21 are respectively provided with a corresponding connecting strip shaped groove 22; the plurality of connecting raised strips 21 and the plurality of connecting bar-shaped grooves 22 are pierced through a plurality of skeleton twisted fiber filaments 1; the non-woven fabric core layer 2 and the skeleton twisted fiber filaments The upper and lower sides of 1 are provided with a surface coating 3; the components and parts by weight of the surface coating 3 are as follows: 100 parts of polypropylene powder, 5 parts of silica gel, 10 parts of polytetrafluoroethylene powder, 5...

Embodiment 2

[0032] Such as figure 1 with 2 As shown, a structurally stable nonwoven fabric includes a nonwoven fabric core layer 2, a skeleton twisted fiber filament 1, and a surface coating 3; Protruding strips 21; the plurality of connecting raised strips 21 are evenly distributed from left to right; the plurality of connecting raised strips 21 are arranged in parallel; the lower sides of the connecting raised strips 21 are respectively provided with a corresponding connecting strip shaped groove 22; the plurality of connecting raised strips 21 and the plurality of connecting bar-shaped grooves 22 are pierced through a plurality of skeleton twisted fiber filaments 1; the non-woven fabric core layer 2 and the skeleton twisted fiber filaments The upper and lower sides of 1 are provided with a surface coating 3; the components and parts by weight of the surface coating are as follows: 100 parts of polypropylene powder, 7 parts of silica gel, 13 parts of polytetrafluoroethylene powder, and...

Embodiment 3

[0040] Such as figure 1 with 2 As shown, a structurally stable nonwoven fabric includes a nonwoven fabric core layer 2, a skeleton twisted fiber filament 1, and a surface coating 3; Protruding strips 21; the plurality of connecting raised strips 21 are evenly distributed from left to right; the plurality of connecting raised strips 21 are arranged in parallel; the lower sides of the connecting raised strips 21 are respectively provided with a corresponding connecting strip shaped groove 22; the plurality of connecting raised strips 21 and the plurality of connecting bar-shaped grooves 22 are pierced through a plurality of skeleton twisted fiber filaments 1; the non-woven fabric core layer 2 and the skeleton twisted fiber filaments The upper and lower sides of 1 are provided with a surface coating 3; the components and parts by weight of the surface coating 3 are as follows: 100 parts of polypropylene powder, 10 parts of silica gel, 15 parts of polytetrafluoroethylene powder, 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com