Array bolt hoisting underframe

An underframe and bolt technology, which is applied in the field of array bolt hoisting underframes, can solve the problems of manpower and material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

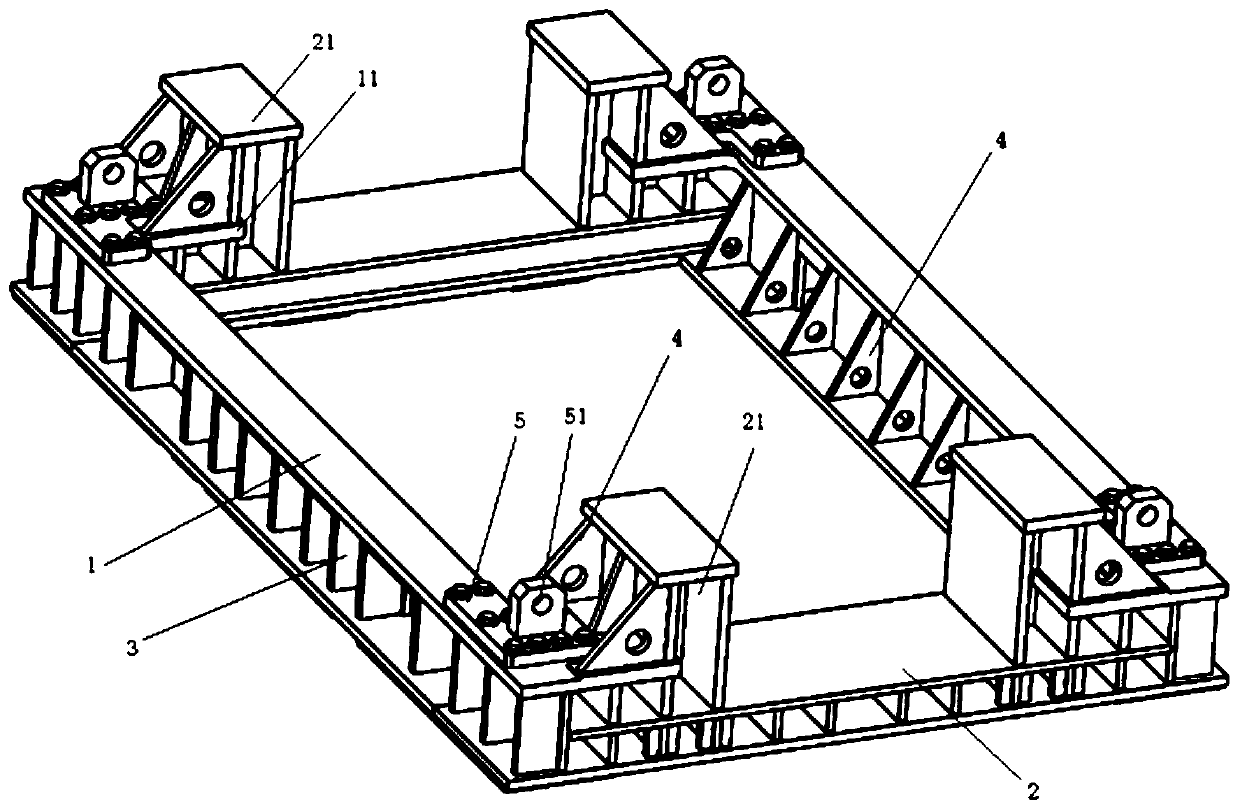

[0015] see figure 1 , an array bolt hoisting chassis of the present invention, comprising a chassis base.

[0016] The chassis base is a rectangular frame structure, which is divided into front bearing side, rear bearing side and two sides. The top plate 2, the bearing top plate 1 and the side top plate 2 are supported on the bottom plate through the support plate 3, the height of the bearing top plate 1 is higher than that of the side top plate 2, and the contact parts of the two are tailor-welded. The inner side of the bearing top plate 1 is provided with triangular support ribs 4 for supporting the bearing top plate 1 on the bottom plate. The bearing top plate 1 is provided with a support platform knot 11 bent toward the side top plate, and the support platform 11 is supported on the side top plate 2 through the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com