Power battery module of electric vehicle and electric vehicle

A technology for electric vehicles and power batteries, applied in the field of electric vehicle power battery modules and electric vehicles, can solve the problems of large size and small installation space, improve energy density and capacity, occupy small space, and improve vibration resistance and resistance. impactful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

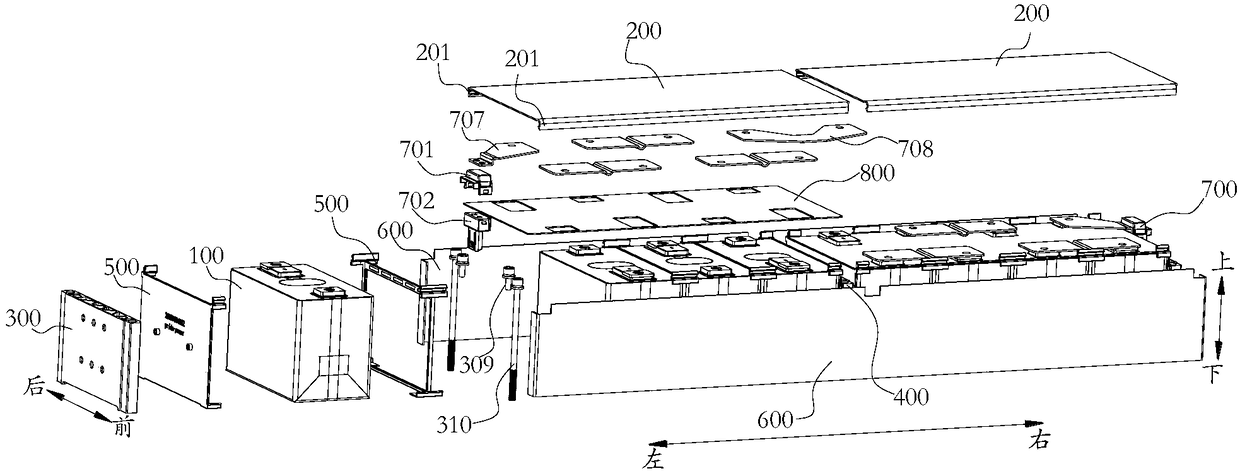

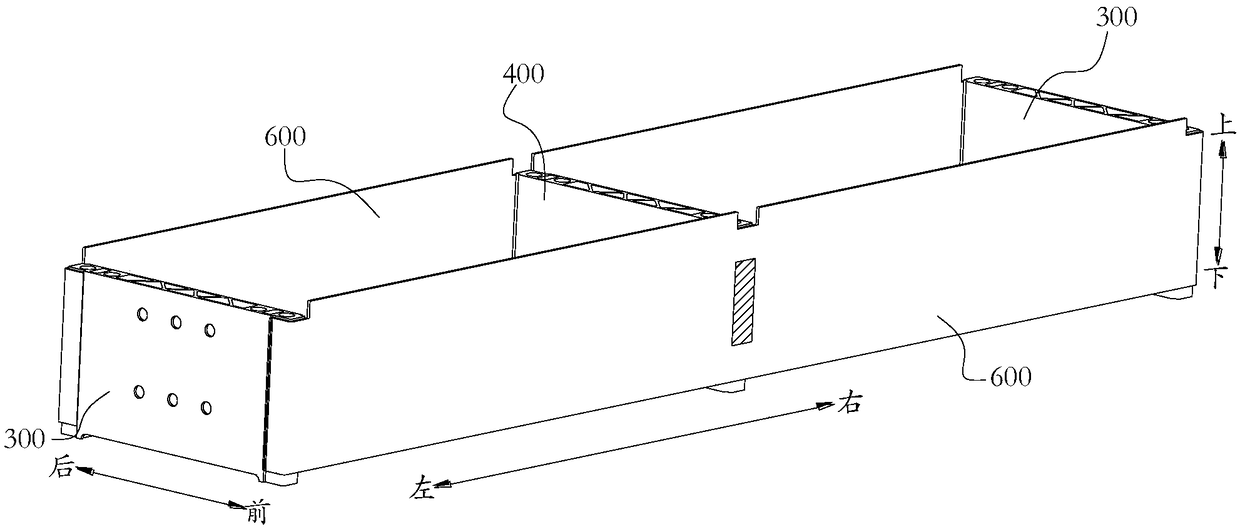

[0060] Such as Figure 1-Figure 11 As shown, an electric vehicle power battery module in this embodiment includes a battery cell 100, an upper cover 200, at least one middle end plate 400, two opposite end plates 300 and two opposite side plates 600, The two end plates 300 are respectively welded to the two side plates 600 to form a shell that is open up and down, and at least one of the middle end plates 400 is welded to the two side plates 600 respectively and the The inner space of the housing is divided into at least two installation cavities, each of which has several battery cells 100 installed therein, and the upper cover 200 is installed on the upper end of the housing. Wherein, the structure of the end plate 300 and the middle end plate 400 is the same, and the middle end plate 400 and the end plate 300 are arranged in parallel. In fact, the side plates of this embodiment are welded to the end plates and the middle end plates respectively by laser galvanometer weldin...

Embodiment 2

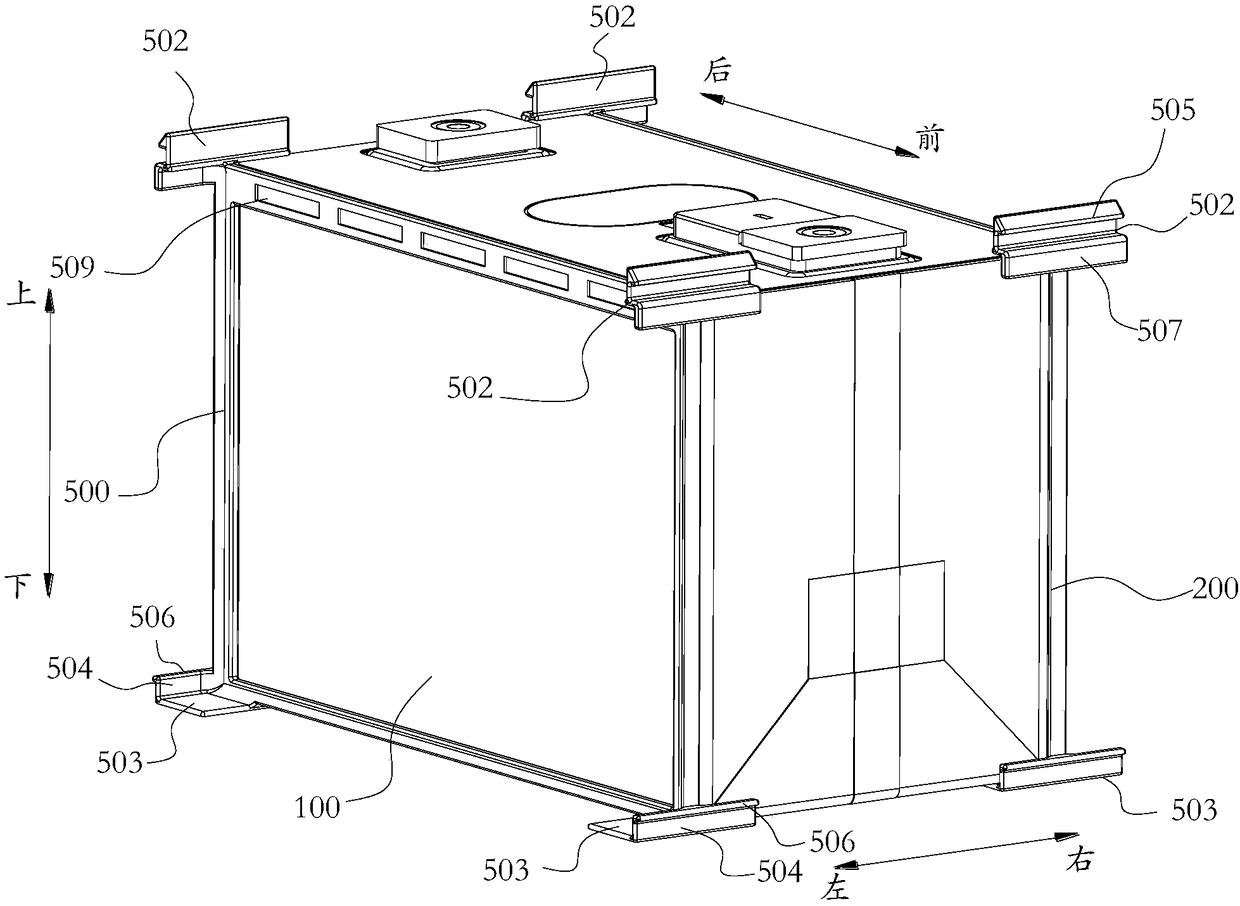

[0064] Such as figure 1 and image 3 As shown, on the basis of Embodiment 1, the battery module of this embodiment can also be between the adjacent cells 100, between the cells 100 and the end plates 300, and between the cells 100 Between the middle end plate 400 and the limit frame 500 that limits the surroundings of the battery core 100, the upper end of the limit frame 500 protrudes from the housing and is connected to the edge of the upper cover 200. Card access. In this embodiment, a limit frame is provided on one side of the battery cell, which can realize the limit of the battery cell in the up, down, left, and right directions, making the entire module structure more stable; and it is also convenient to clamp and fix the upper cover. That is to say, in this embodiment, adjacent battery cells, battery cells and end plates, and battery cells and intermediate end plates are all spaced apart, and the up, down, left, and right directions of the cells are limited to preven...

Embodiment 3

[0084] An electric vehicle includes a vehicle body and the above-mentioned battery module for powering the vehicle body.

[0085] In the electric vehicle of this embodiment, the overall installation structure of the battery module is formed by connecting the middle end plate, the end plate and the side plate, so that the number of battery cells accommodated by the battery module is increased, which is even equivalent to two or more independent modules. Compared with two or more independent modules, the present invention reduces the size in the length direction, increases the length of the module, takes up less space, improves the unity of the module, and saves battery internal space. Space, the overall structure of the module is more compact, which improves the space utilization rate, thereby increasing the energy density and capacity of the entire battery system; and the number of components used is also reduced, achieving the effect of weight reduction; in addition, the setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com