Multi-spoke-ring gas and liquid separator

The technology of a gas-liquid separation device and spokes is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., and can solve the problem of low removal efficiency of the gas-liquid separation device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

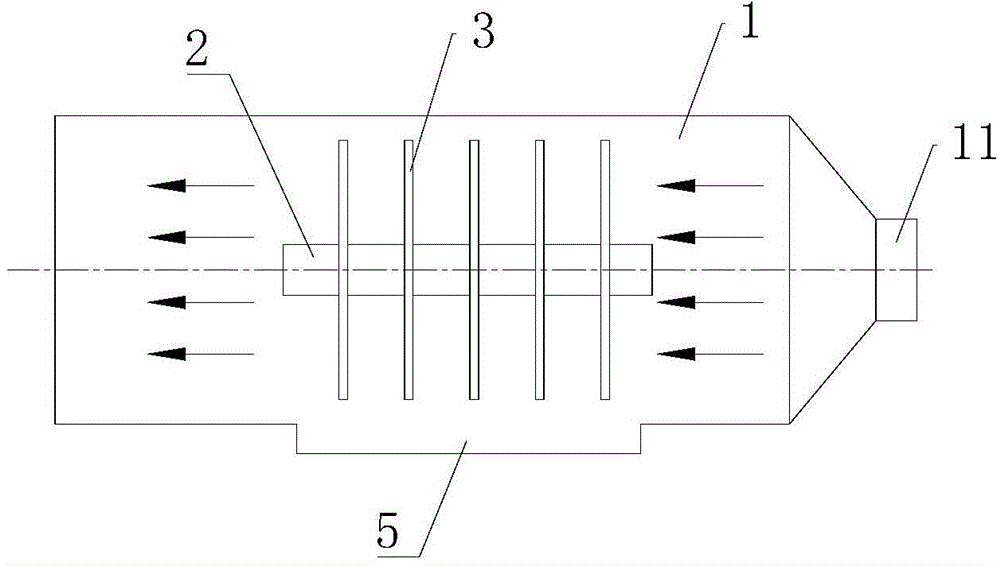

[0020] Such as figure 1 As shown, it is an embodiment of the multi-spoke gas-liquid separation device of the present invention. The multi-spoke gas-liquid separation device first includes a demist chamber 1 for water mist or oil mist to pass through, and the water mist or oil mist is removed from the demister. The mist inlet 11 on the right side of the mist chamber 1 enters, and then is discharged from the outlet on the left side, and the removal of water mist or oil mist is completed inside the demist chamber 1 .

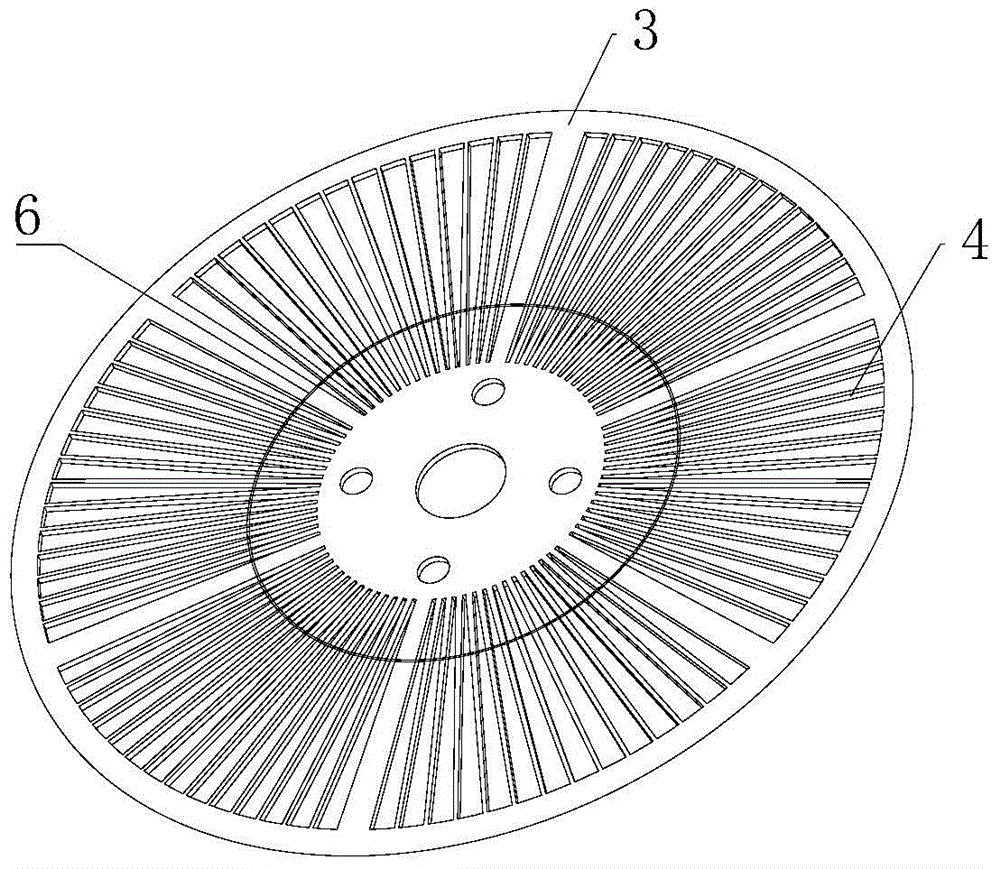

[0021] In the defogging chamber 1, a rotating shaft 2 is firstly arranged, and the rotating shaft 2 is driven by a motor (not shown in the figure) to rotate at a high speed, and multiple (five shown in the figure) are fixed side by side on the rotating shaft ) and the defogging ring 3 that rotates synchronously with it, and the plane where each defogging ring 3 is located is perpendicular to the axial direction of the rotating shaft 2. That is, the directions of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com