Ammonia gas absorption treatment device of mixing mill

A processing device and kneader technology, which are applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of ineffective use of ammonia water for maintenance and difficult cleaning of ammonia pools, so as to avoid damage to the human body, save resources, The effect of avoiding pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

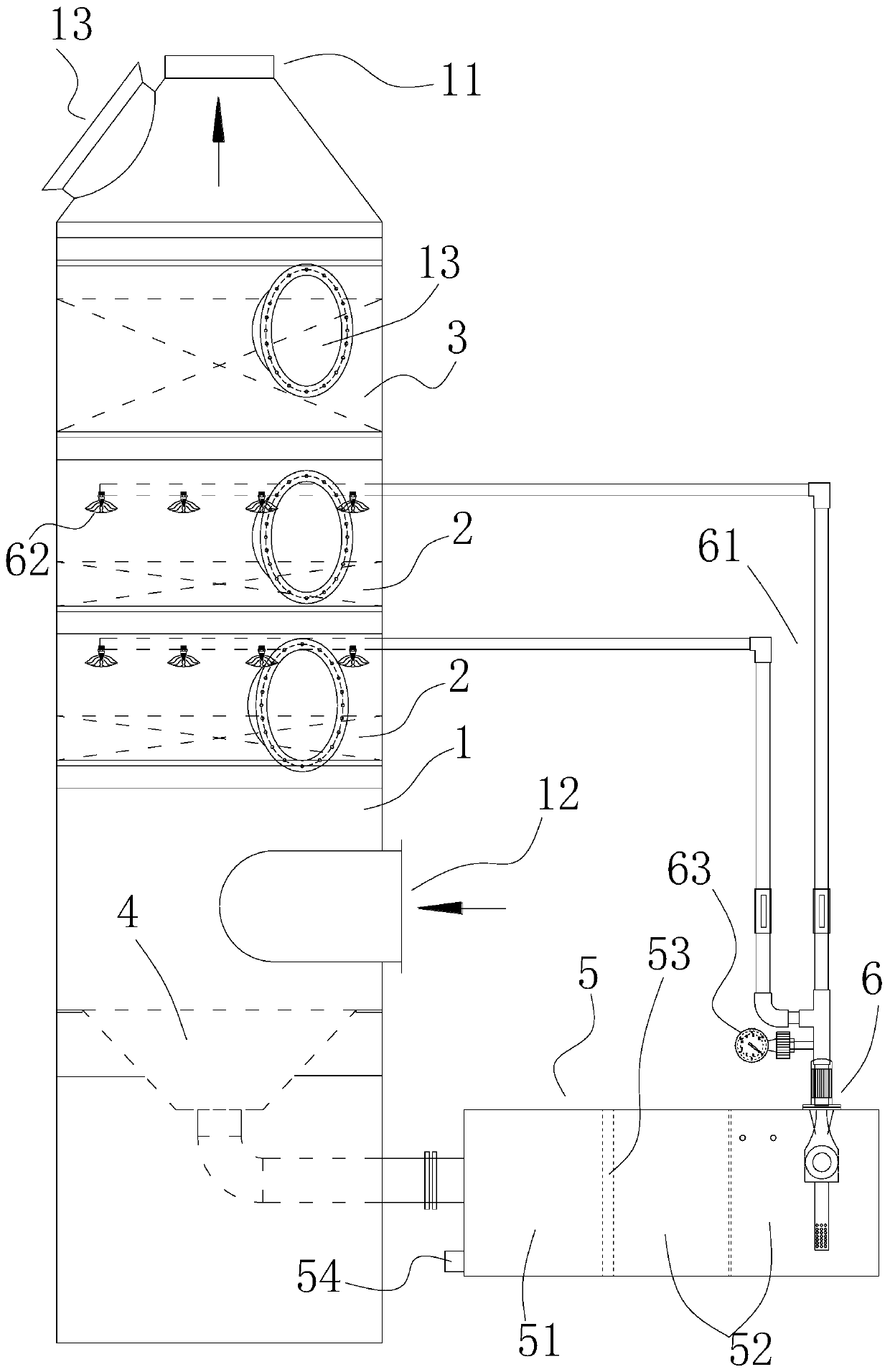

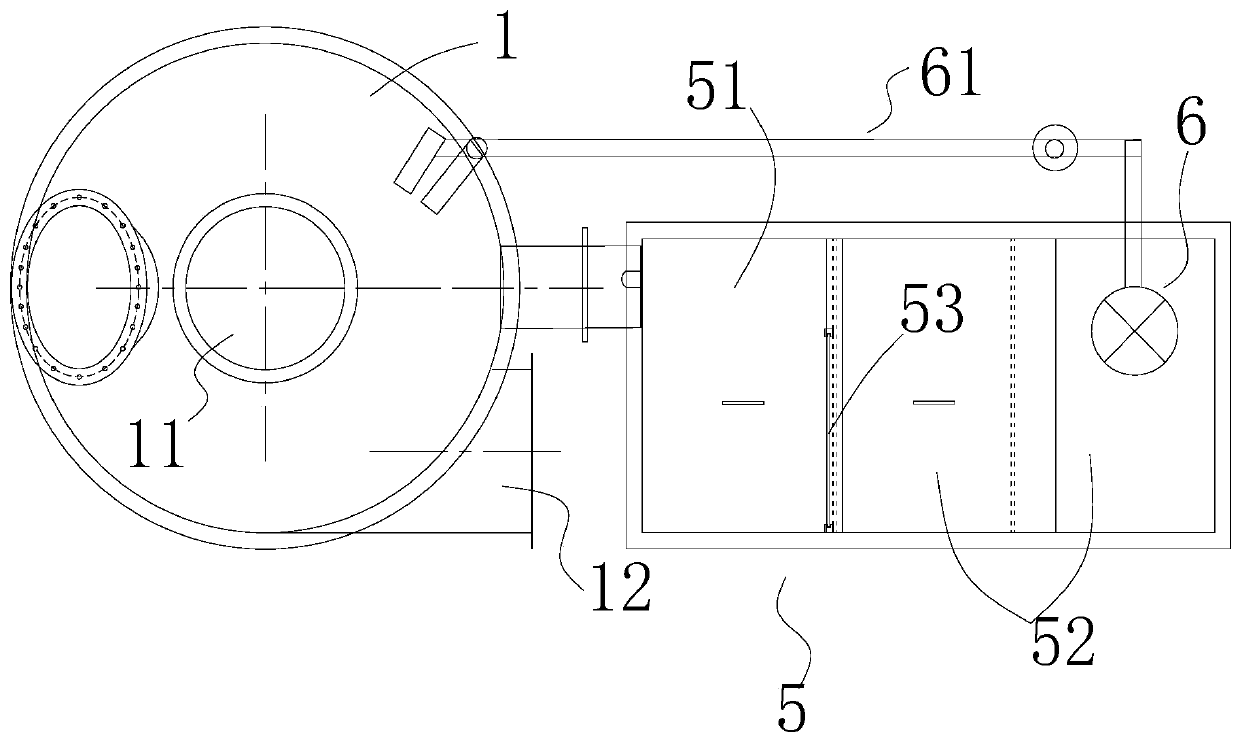

[0045] Such as figure 1 As shown, a kneader ammonia absorption treatment device includes a treatment tower 1, a first packing 2, a second packing 3, a cone bucket 4, a water tank 5, a first water pump 6, and a control unit.

[0046] Such as figure 1 As shown, the processing tower 1 is in the shape of a cylinder as a whole, and its top is provided with small and large heads, and the small ends of the large and small heads face upward.

[0047] Such as figure 1 As shown, the first packing 2 is set in the processing tower 1, the first packing 2 adopts Raschig ring or Pall ring, the second packing 3 is arranged above the first packing 2, the second packing 3 adopts multi-faceted hollow spheres, and the top of the processing tower 1 Air outlet 11 is set.

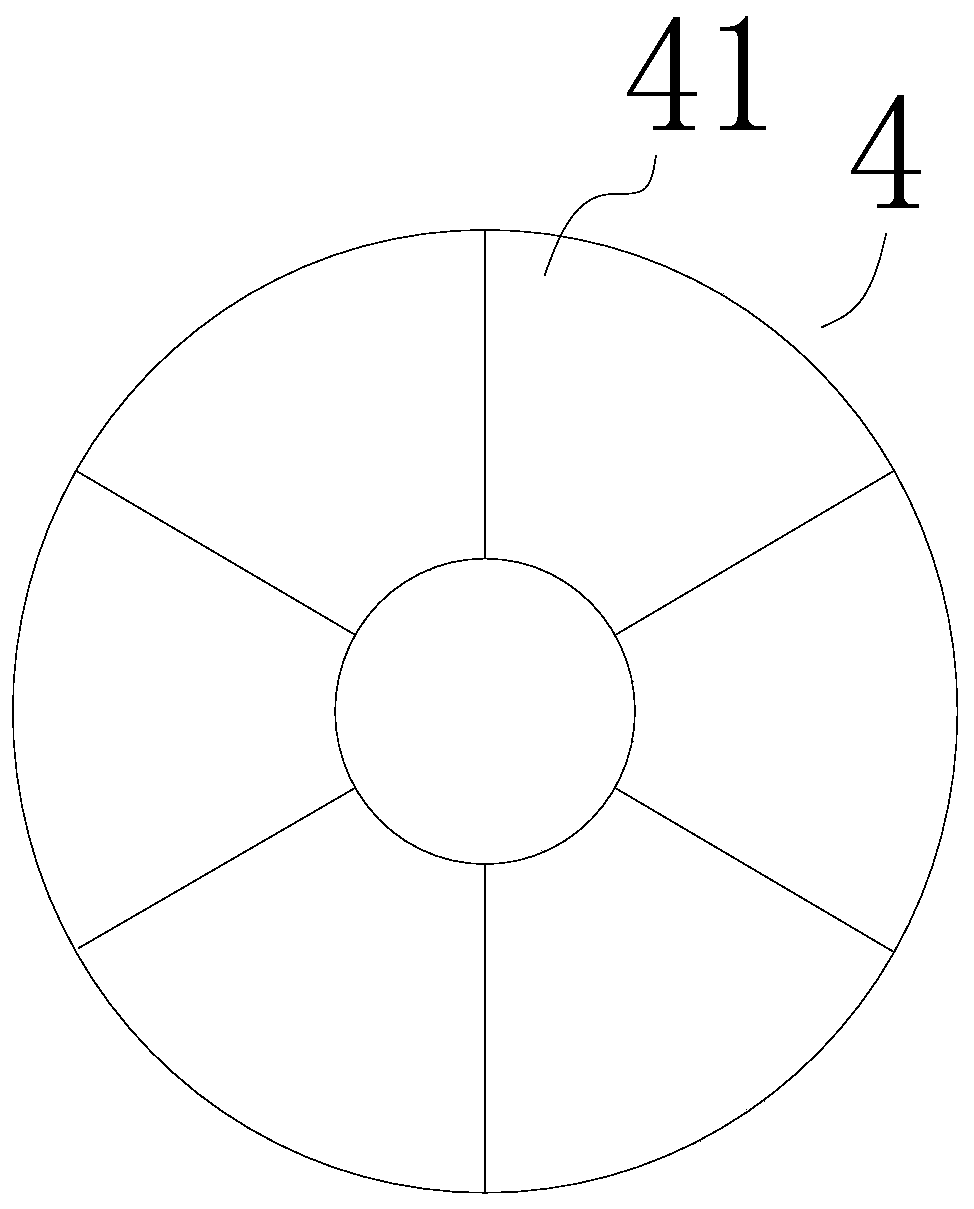

[0048] Such as figure 1 , 3 As shown, the bottom of the first packing 2 is provided with a cone bucket 4 with an upward opening, and the cone bucket 4 is large and small at the bottom. Six; all the flat plates 41 are formed...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is:

[0059] There are at least two processing towers 1. In this embodiment, there are three processing towers 1. All processing towers 1 are connected in series. With the direction of gas flow as the rear, the air outlet 11 of the previous processing tower 1 leads to the rear one. The air inlet 12 of the processing tower 1, and the air outlet 11 of the rearmost processing tower 1 are provided with an induced draft device. outlet.

[0060] working principle:

[0061] Such as figure 1 Shown, a kind of kneading machine ammonia absorption treatment device among the present invention is in practical application, and the ammonia gas from kneading machine enters in the treatment tower 1 from air inlet 12, and then ammonia gas flows upwards, and the first water pump 6 will The water pump in the water outlet area 52 is sent to the water pipe 61, and is sprayed onto the first packing 2 through the nozzle 62. The ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com