Mineral mining crusher for mine

A crusher and mineral technology, applied in grain processing and other directions, can solve the problems that affect the efficient use of impact crushers, the hammer head and impact plate are easy to stick to sticky materials, and stick to the plate hammer, etc., to increase rigidity, The effect of preventing excessive smoke and increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

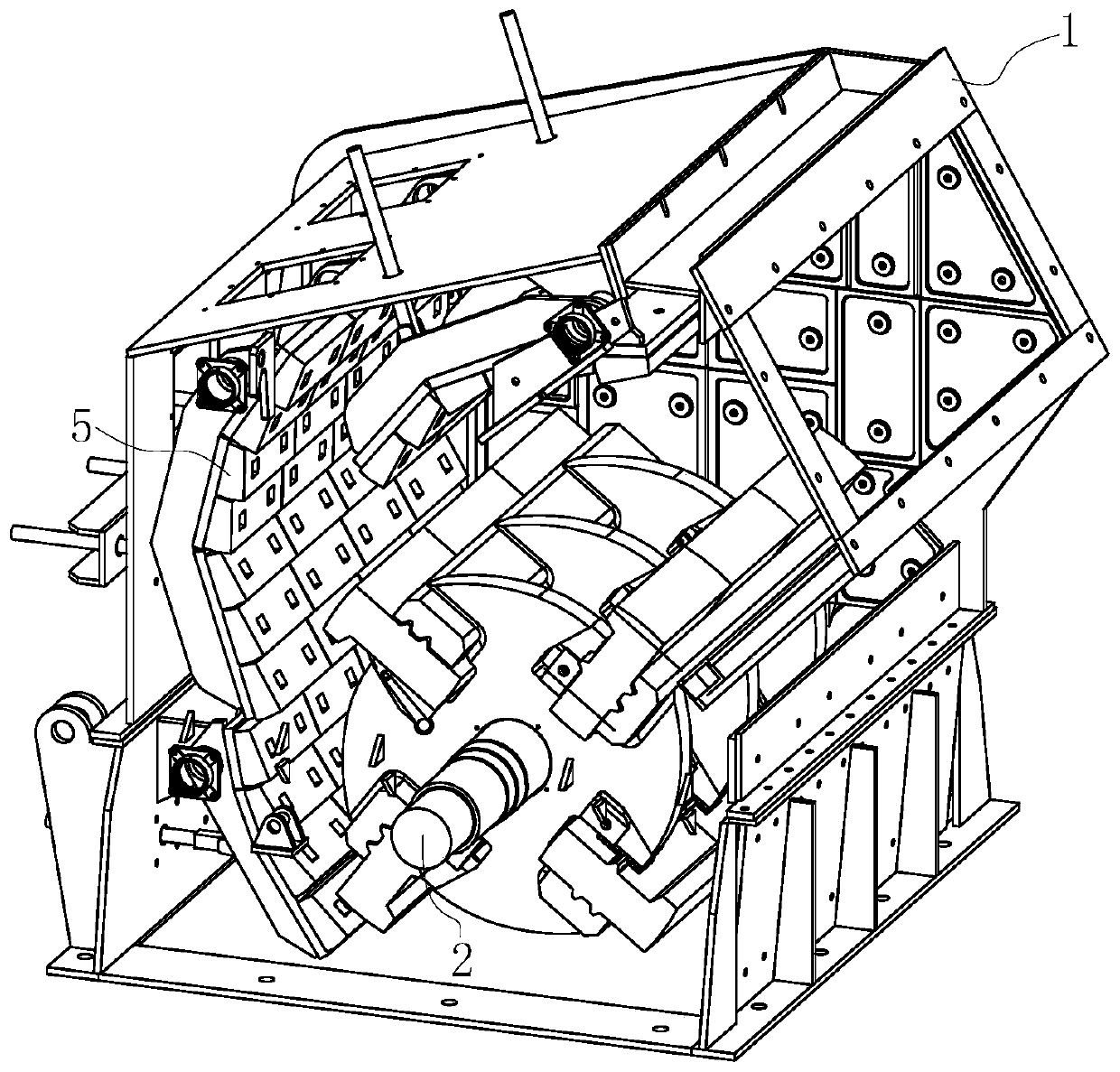

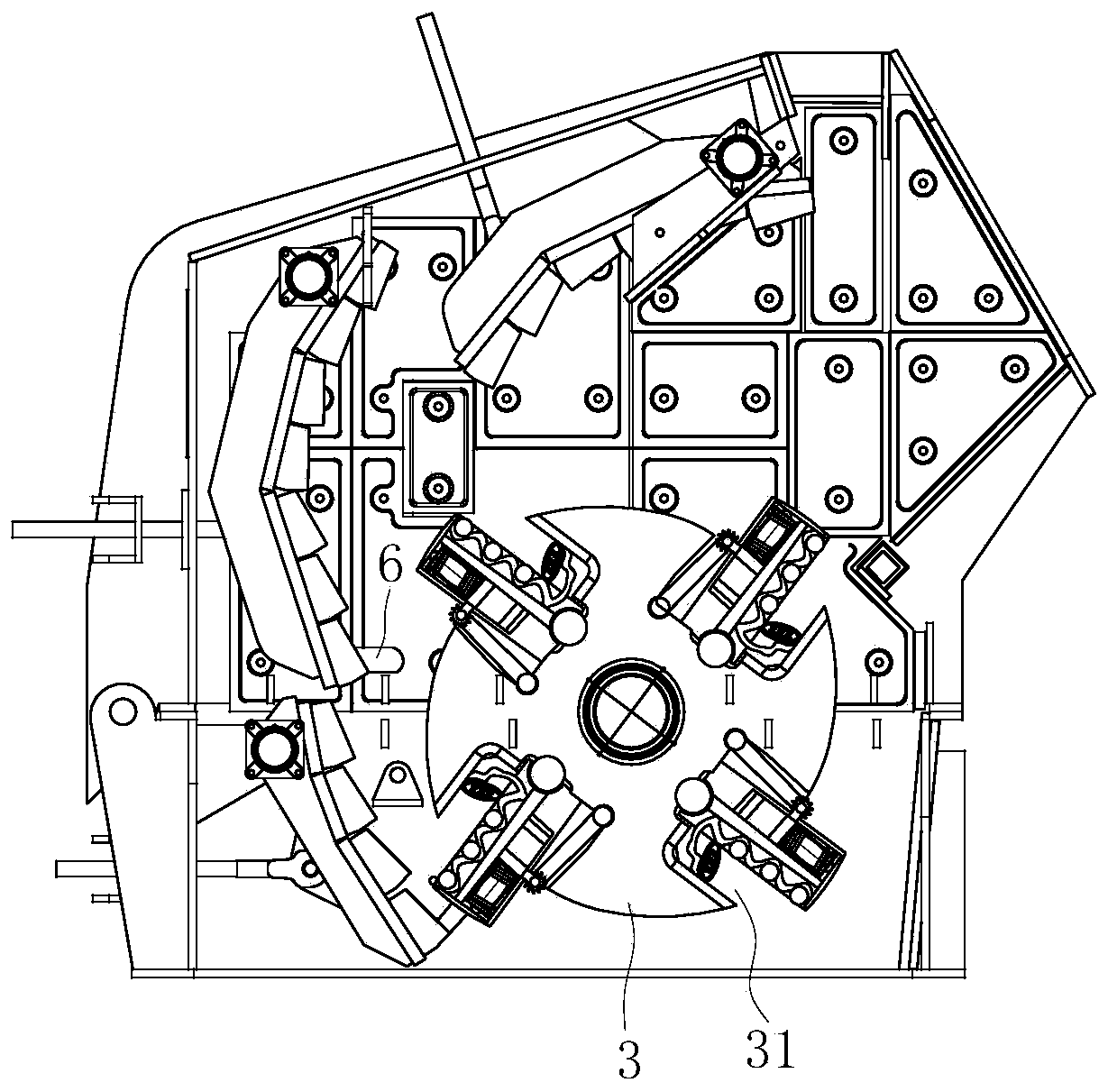

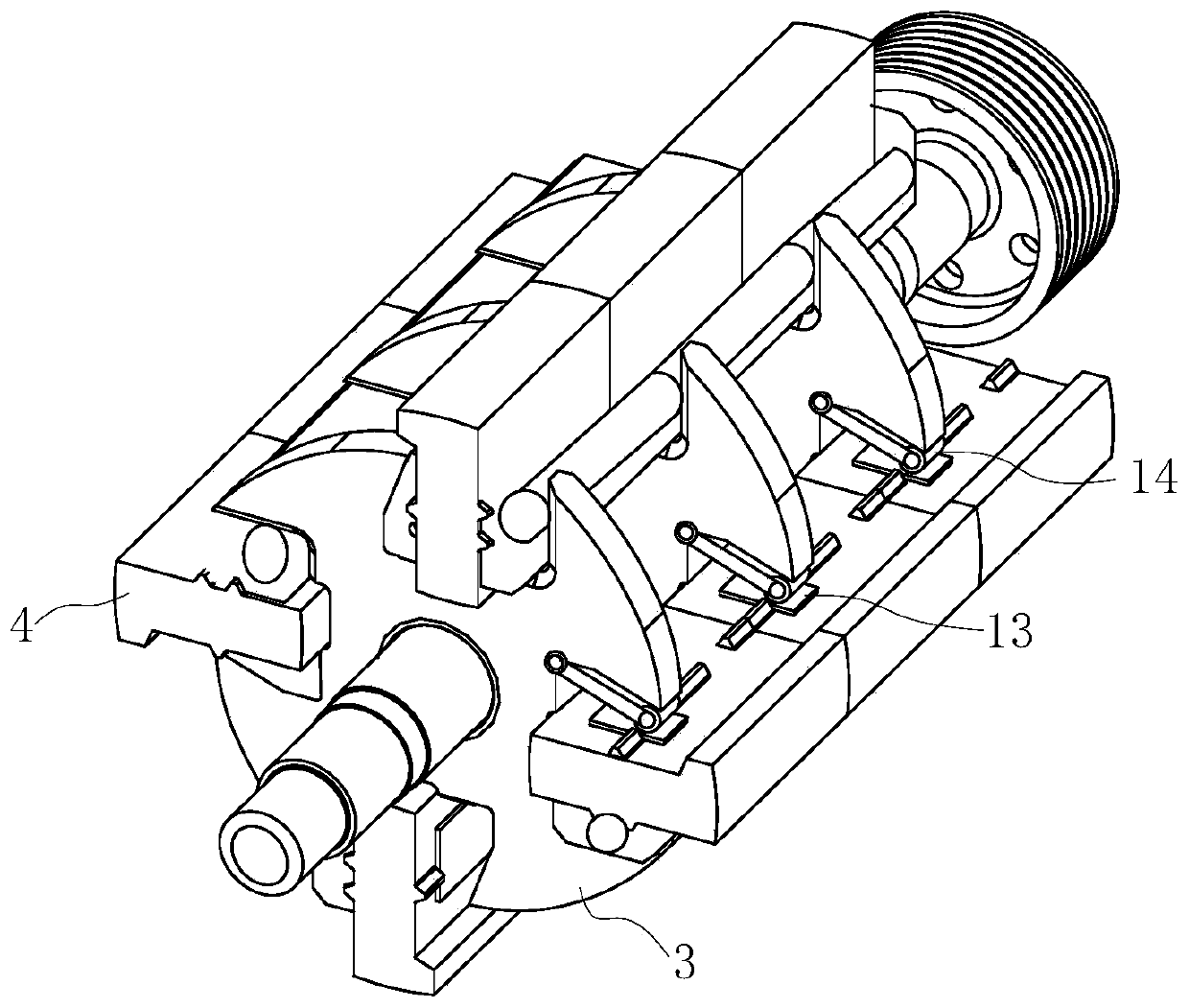

[0023] use Figure 1-Figure 5 A mineral extraction crusher for mines according to an embodiment of the present invention will be described below.

[0024] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, a mining crusher for mines according to the present invention includes a frame 1, a rotor 2, a shaft frame 3, a blow bar 4 and an impact plate 5; the rotor 2 is arranged in the frame 1, and the rotor 2 is evenly sleeved with a rotating shaft frame 3, and the rotating shaft frame 3 is provided with a blow bar 4; above the rotor 2, there are a plurality of counterattack plates 5, and the counterattack plates 5 are connected to the frame 1 through the counterattack frame; The bottom end of the impact plate 5 is evenly provided with elastic wear-resistant blocks 6 in the horizontal direction; the shaft frame 3 is evenly provided with a mounting groove 31, and a blow bar 4 is hinged in the mounting groove 31 through a hinge column; the blow bar 4 One side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com