Multi-station hanging tool for automatic machining sand blasting equipment

A sandblasting equipment and machining technology, used in metal processing equipment, used abrasive treatment devices, manufacturing tools, etc., can solve problems such as poor workpiece fixing and clamping effect, workpiece falling off, and slow workpiece sandblasting treatment efficiency. , to achieve the effect of improving sandblasting processing efficiency, ensuring processing quality and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

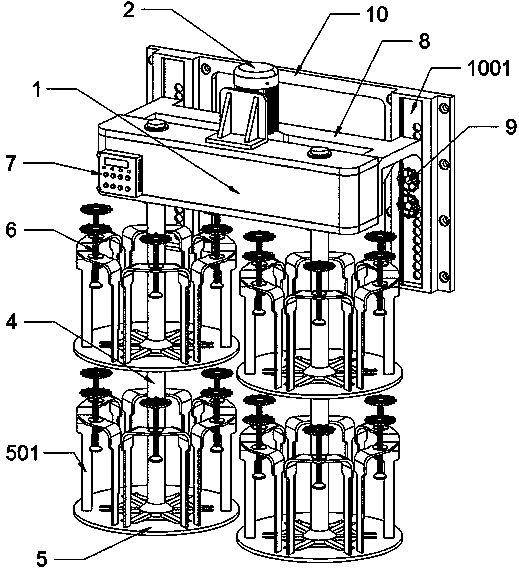

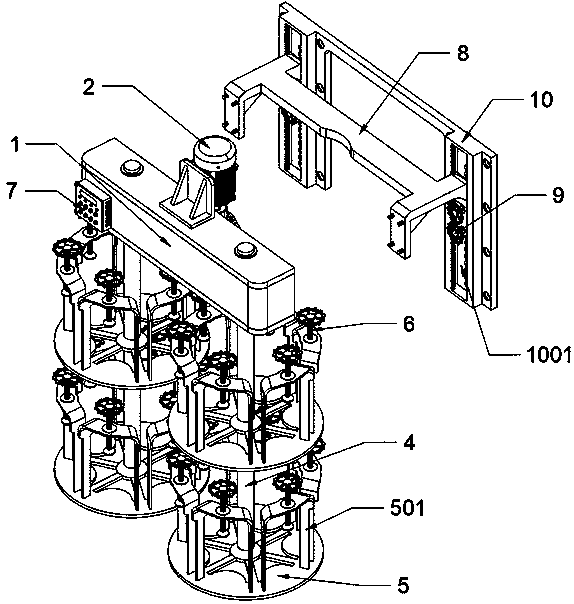

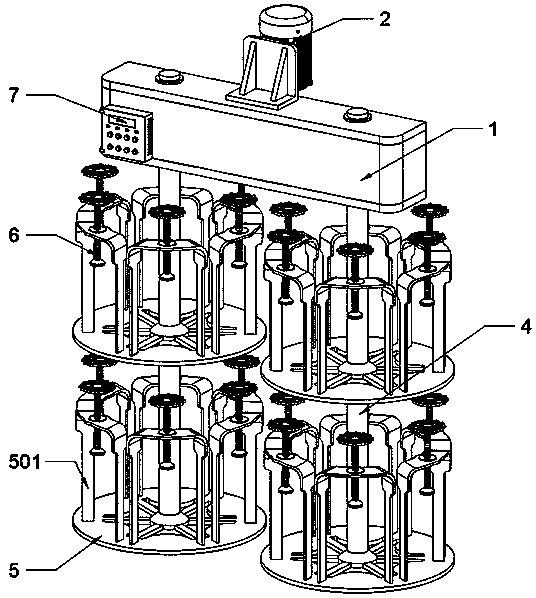

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a multi-station suspension tool for automatic mechanical processing sandblasting equipment, including a main body 1, a driving motor 2, a driving pulley 201, a synchronous belt 3, a suspension rotating rod 4, a driven pulley 401, and a station Ring plate 5, N-type limit frame 501, fixed screw rod 6, control electric box 7, support frame 8, limit bolt 9, connecting seat 10 and adjustment chute 1001; the inside of the main body 1 is hollow, and the main body 1 The support frame 8 is installed on the front end of the connecting seat 10; the driving motor 2 is installed on the top of the rear side of the main body 1 in an inverted shape, and the driving motor 2 is connected to the control electric box 7 through a power line; the rotating shaft at the bottom of the driving motor 2 passes through the bearing Rotationally connected to the outside of the rear side of the main body 1, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com