Multi-layer wave spring winding device and winding method

The technology of a wave spring and a winding method is applied in the production field of a multi-layer wave spring, and can solve the problems of sector deformation, the deviation of the coaxiality between the multi-layer wave spring coil and the coil, the unsatisfactory winding method of the multi-layer wave spring, etc. The effect of eliminating gaps and ensuring coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The processing technology of multi-layer wave spring is: blanking → fitter → lathe winding → preliminary processing → cold stamping mold pressing → heat treatment setting → finishing → supplementary tempering → inspection → summary inspection.

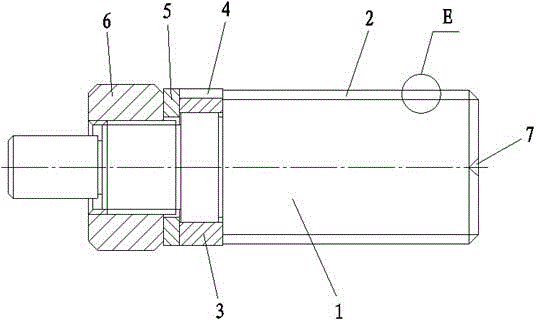

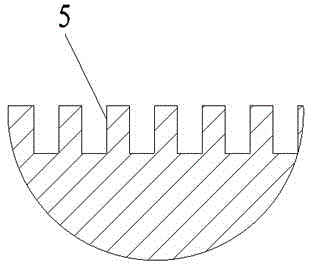

[0018] The winding device of multi-layer wave spring is as figure 1 As shown, including a mandrel 1, a rectangular spiral groove 2 is provided on the surface of one end of the mandrel 1, and a collar 3 is sleeved near the end of the rectangular spiral groove 2, and an axial through groove 4 is provided on the circumference of the collar 3, The nut 6 compresses and fixes the collar 3 on the mandrel 1 through the washer 5 , so that the through groove 4 on the collar 3 is aligned with the starting end of the rectangular spiral groove 2 . Such as figure 2 As shown, the groove width of the rectangular spiral groove 2 is 1.5 mm, and the groove depth is 2.2 mm; the groove width of the through groove 4 is 1.6 mm, and the groove de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com