Surface machining device and method aiming at bending metal pipes of small specifications

A metal pipe and surface processing technology, which is applied in metal processing equipment, grinding drive devices, manufacturing tools, etc., can solve the problem that the diameter of metal pipes is small, the grinding mechanism cannot extend into the interior, and the inner wall of the bend of small-sized metal pipes cannot be solved. Wrinkle grinding and other problems to achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

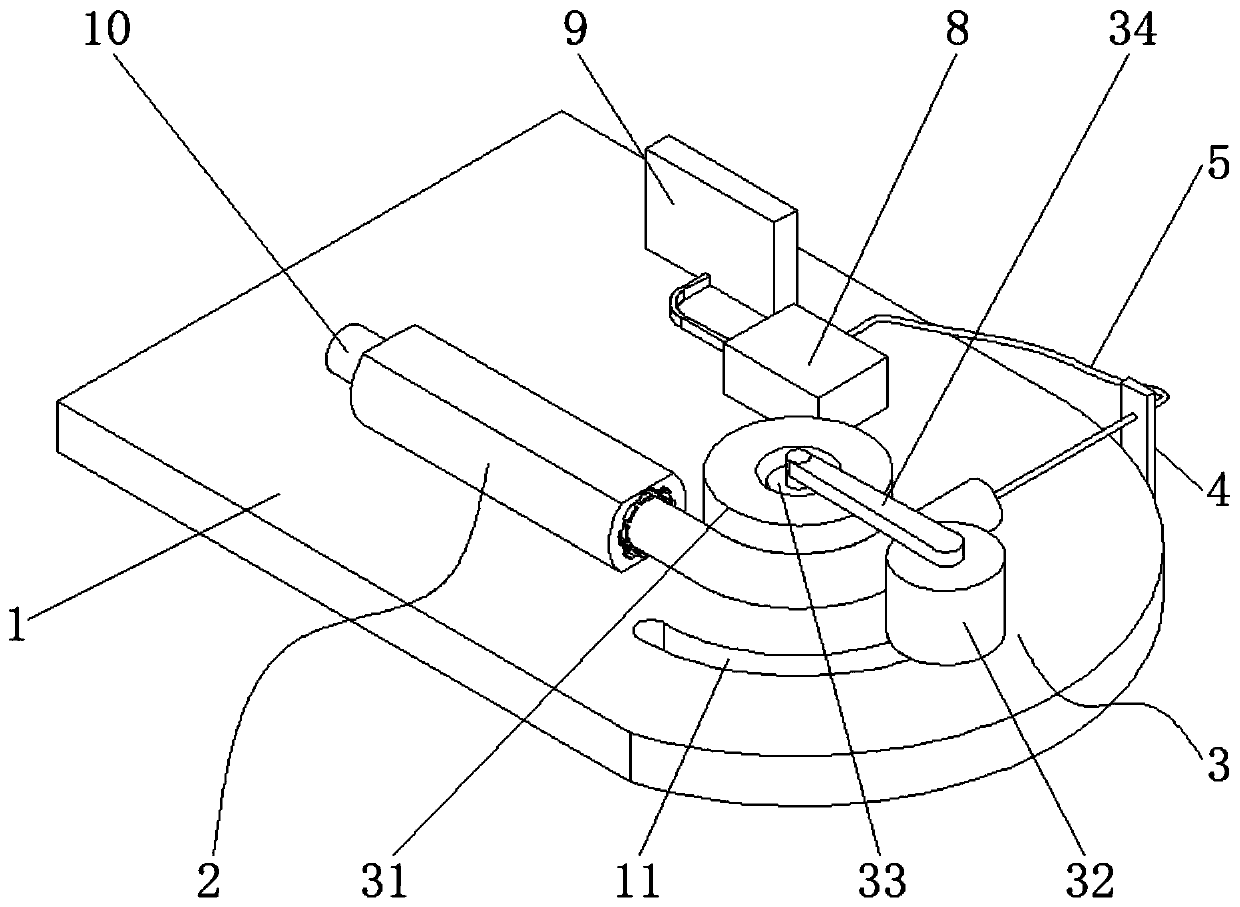

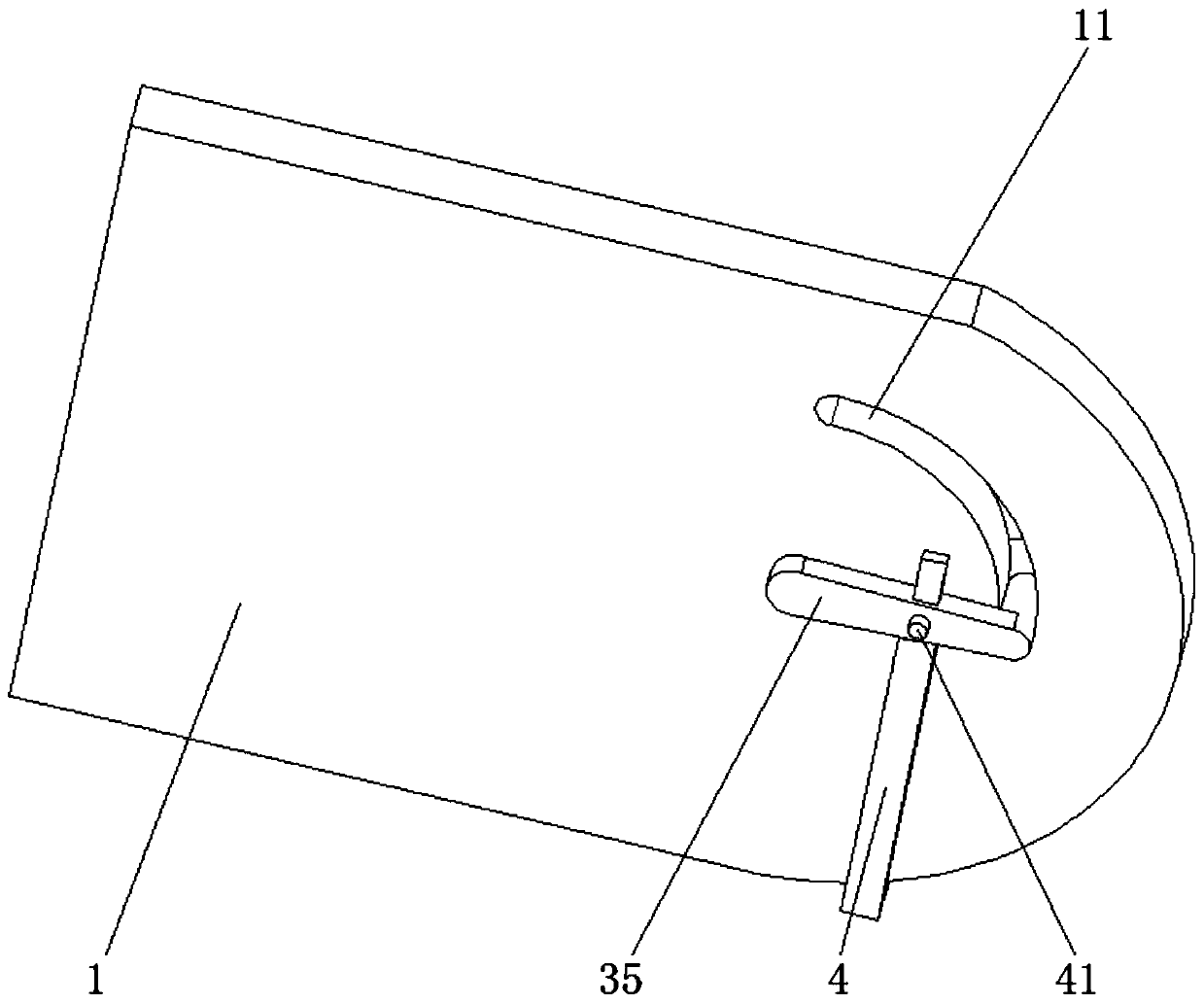

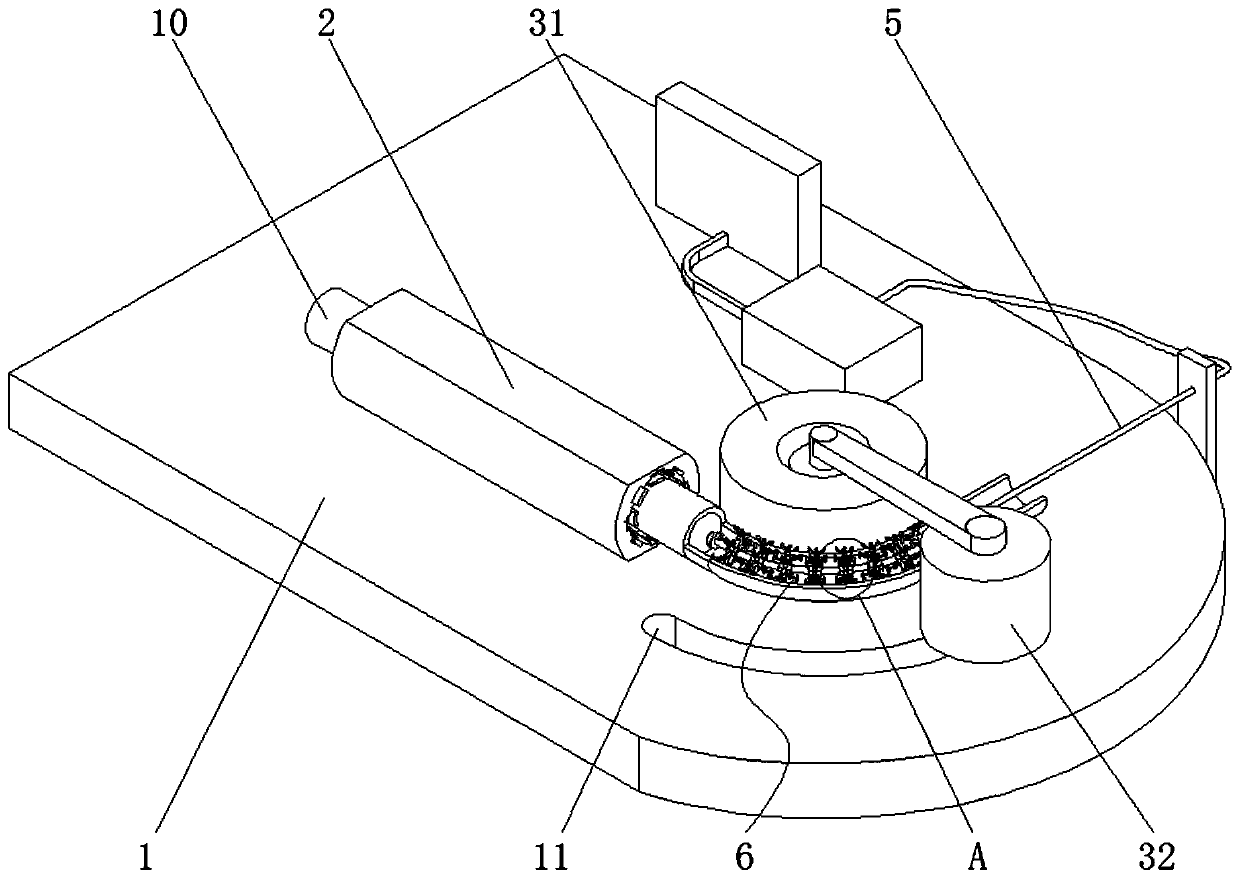

[0036] Embodiments of the present invention provide a surface processing device and method for bending small-sized metal pipes, such as Figure 1-8 As shown, it is used to bend the pipe body 10. It includes a workbench 1, a placement slot 2, a bending mechanism 3, a support rod 4, a cable 5 and a plurality of grinding mechanisms 6. The placement slot 2 is welded on the workbench 1. The bending mechanism 3 is arranged on one side of the placing groove 2 . The bending mechanism 3 is used to bend one end of the pipe body 10 . The pipe body 10 extends into the bending mechanism 3 through the placement slot 2 . The bending mechanism 3 includes a limiting column 31, a pressing roller 32 and a driving assembly. The limit post 31 is welded with the workbench 1 . The pressure roller 32 is slidingly matched with the workbench 1 through the driving assembly. combined with figure 1 , 2 As shown, one end of the pipe body 10 extends between the limiting column 31 and the pressure ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com