Material rapid crushing device

A crushing device and fast technology, applied in the direction of grain processing, etc., can solve problems such as indigestion, poor taste of feed, unfavorable mixing of materials, etc., and achieve the effect of reasonable design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

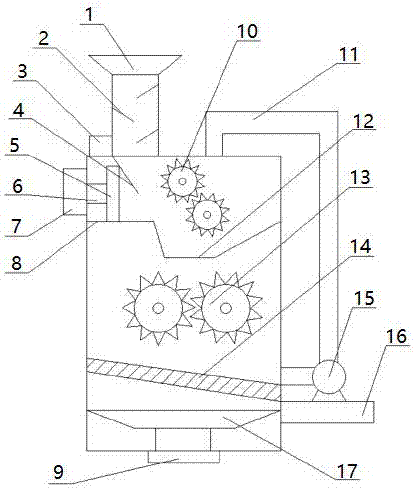

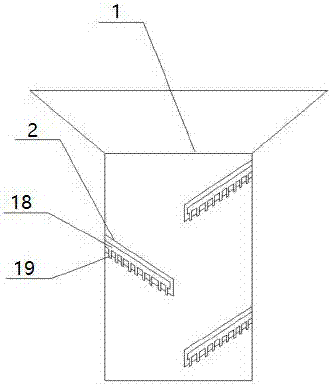

[0016] Such as Figure 1-2 As shown, a material rapid crushing device includes a crushing shell, a crushing group 13 and a small crushing roller 10 are arranged inside the inner body, the small crushing roller 10 is arranged at the upper end of the casing, and a bearing is arranged on the left side of the small crushing roller 10. Material plate 8, a pusher plate 5 is placed above the material receiving plate 8, the left side of the pusher plate 5 is connected to the push rod 6, and the push rod 6 is connected to the cylinder 2 outside the shell, and the upper end of the shell is provided with a feed hopper 1, which feeds A hot air blower 3 is provided at the connection between the hopper 1 and the shell, and a guide hopper 12 is provided in the middle of the material receiving plate 8. The crushing group 13 provided in the shell is located below the guide hopper 12, and an inclined vibration is provided below the crushing group 13. A sieve plate 14, a receiving funnel 17 is p...

Embodiment 2

[0021] Such as figure 1 , 2 As shown, when a material rapid crushing device of the present invention is actually used, the material is put in from the feed hopper 1, dried, and the material is buffered by the material guide plate 2 to prevent the accumulation of the material. After the material enters the housing, , falls on the material receiving plate 8, and then the pushing plate 5 starts to move to the right, so that the blocking plate 4 closes the feeding port, and pushes the material down to the right, and the material is crushed by the small crushing roller 10, and the crushed The material enters the crushing group 13 through the guide hopper 12 for secondary crushing. After the crushed material is screened by the vibrating sieve plate 14, the qualified material falls out from the discharge port 17, and the unqualified material is transported to the small group by the hoist 15. The right side of the crushing roller 10 performs circulating crushing.

[0022] The conven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com