Processing technology of dreg-free hotpot condiment

A technology of hot pot bottom material and processing technology, which is applied in the field of food processing, can solve the problem of hot pot bottom material containing slag, achieve the effects of less filtration, obvious processing efficiency, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

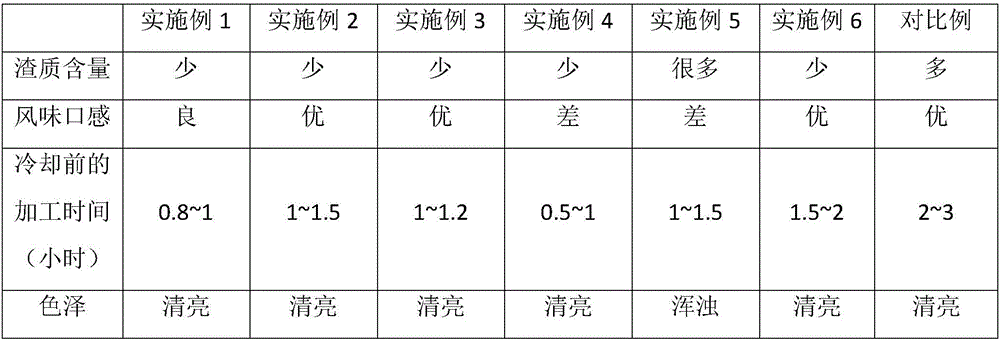

Examples

Embodiment 1

[0023] Embodiment 1: a kind of processing technology of slag-free chafing dish bottom material adopts following processing steps:

[0024] A. Take butter, chili pepper and Zanthoxylum bungeanum with a ratio of parts by mass of 10:3:2, rinse the chili pepper and Zanthoxylum bungeanum with water for 2 minutes, remove and filter dry, heat the butter to 90°C to melt, and drain the dried chili pepper Add the pepper and pepper to the butter and fry for 15 minutes. After frying, filter the pepper and pepper to get the main cooking oil;

[0025] B. Soak Kaempferia, Poria, Yam, Angelica dahurica, Tsao Guo, Luo Han Guo, Bai Kou, Gardenia, Amomum granules, and Algal ginger in water for 10 minutes, then soak in white wine for 5 minutes, filter and dry with butter and soybean oil Fry the mixed oil for 5 minutes, the frying temperature is 60°C, the mass ratio of butter and soybean oil is 2:5, then add water and cook for 30 minutes, the volume ratio of water and mixed oil is 1:1.5, filter ou...

Embodiment 2

[0031] Example 2. The difference between this example and Example 1 is that a 30-mesh cage filter 1 is used. In step A, the chili and Chinese prickly ash are fried and boiled in 100°C butter for 20 minutes; in step B, the spices are soaked in water Then soak in white wine for 8 minutes, then stir-fry with mixed oil for 10 minutes at 80°C, then add water and boil for 50 minutes; in step C, stir-fry spices for 20 minutes, stir-fry at 80°C, add water and boil for 50 minutes minute; in Step E, heat to 180°C and then keep it warm for 10 minutes; in Step F, let stand at 10°C.

Embodiment 3

[0032] Example 3. The only difference between this example and Example 1 is that a 24-mesh cage filter 1 is used. In step A, peppers and Chinese prickly ash are fried in butter at 95°C for 18 minutes; in step B, spices are soaked in water Then soak in white wine for 7 minutes, then stir-fry with mixed oil for 8 minutes at a temperature of 70°C, then add water to boil for 40 minutes; in step C, stir-fry spices for 18 minutes at a temperature of 70°C, add water to boil for 40 minutes Minutes; heat to 150°C in Step E and keep warm for 9 minutes, and stand at 8°C in Step F.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com