Injection molding technology of composite panel

An injection molding process and composite panel technology, applied in the direction of flat products, household appliances, and other household appliances, can solve the problems of less color, monotony, etc., and achieve the effects of improving quality, reducing production steps, and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] As described in the accompanying drawings, the present invention adopts the injection molding process of the composite panel, which comprises the following steps:

[0033] ①Select the film;

[0034] ②Print patterns on the film; adopt color screen printing; the screen used can use a screen with a diameter of about 34μ to make the pattern more beautiful. Under the ink properties will not change. ;

[0035] ③ Printing adhesive ink on the film; the adhesive ink used, its composition includes at least the following: synthetic resin, 3-methoxy-3-methylbutyl acetate, aromatic hydrocarbons, 1, 3, 5 three Toluene, isophorone;

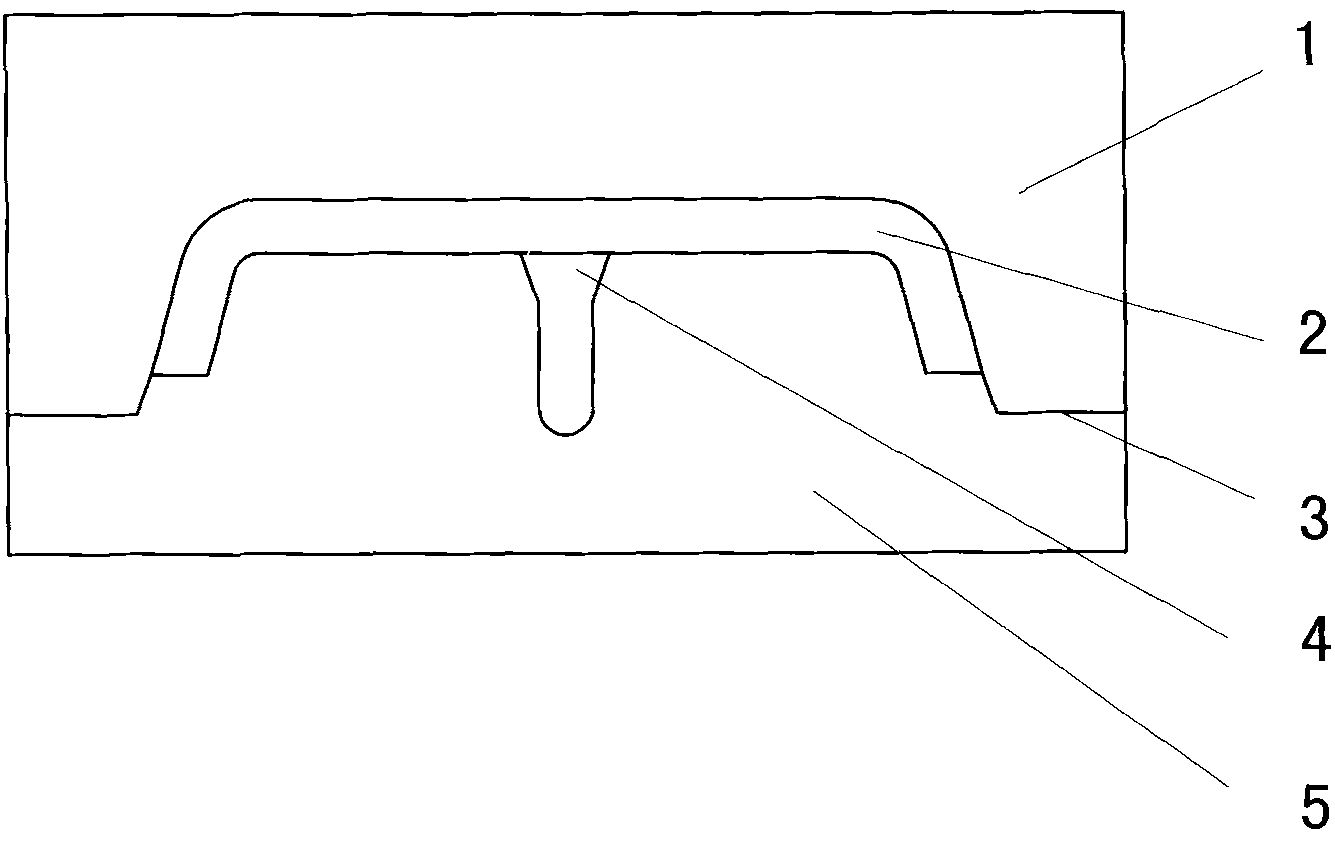

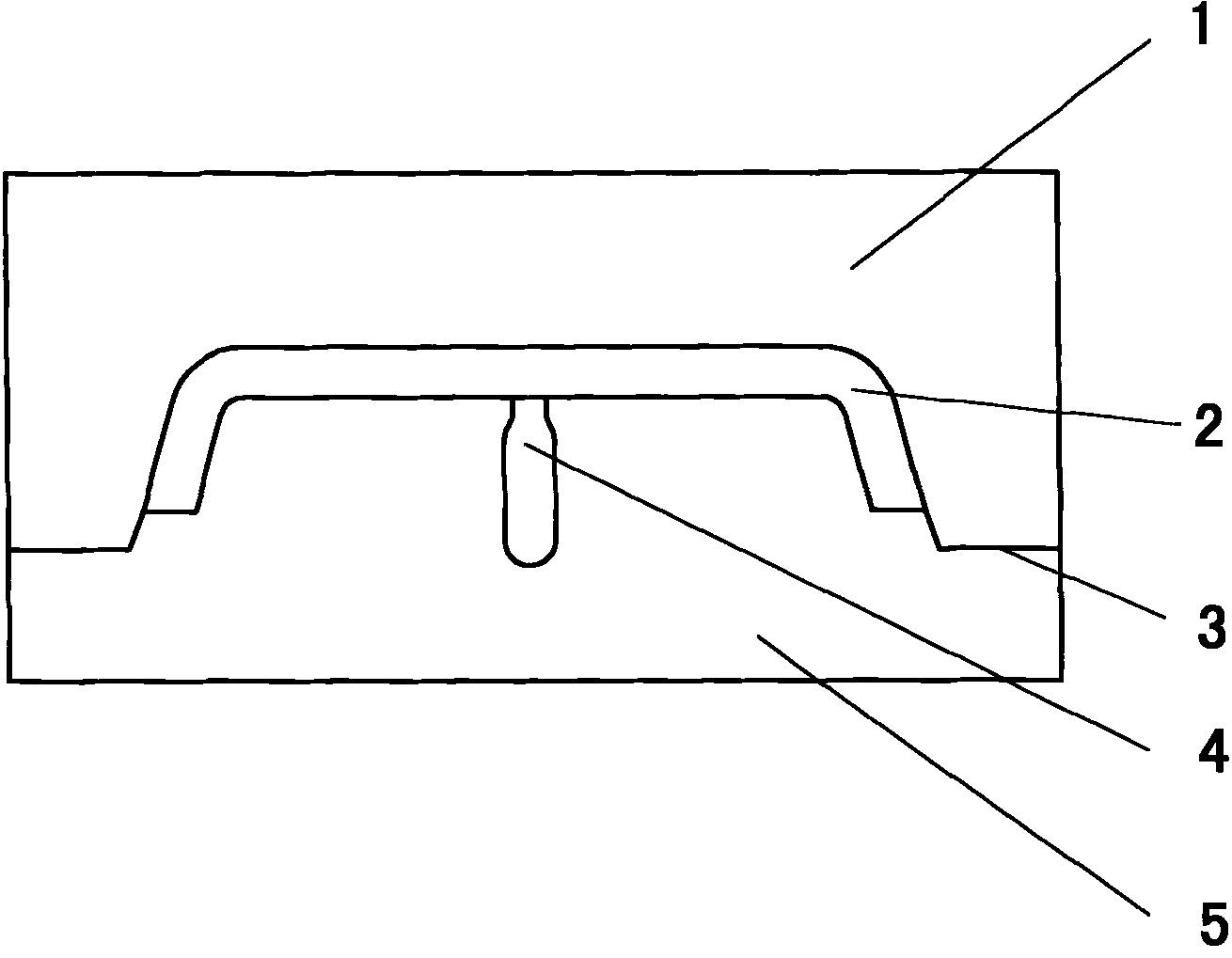

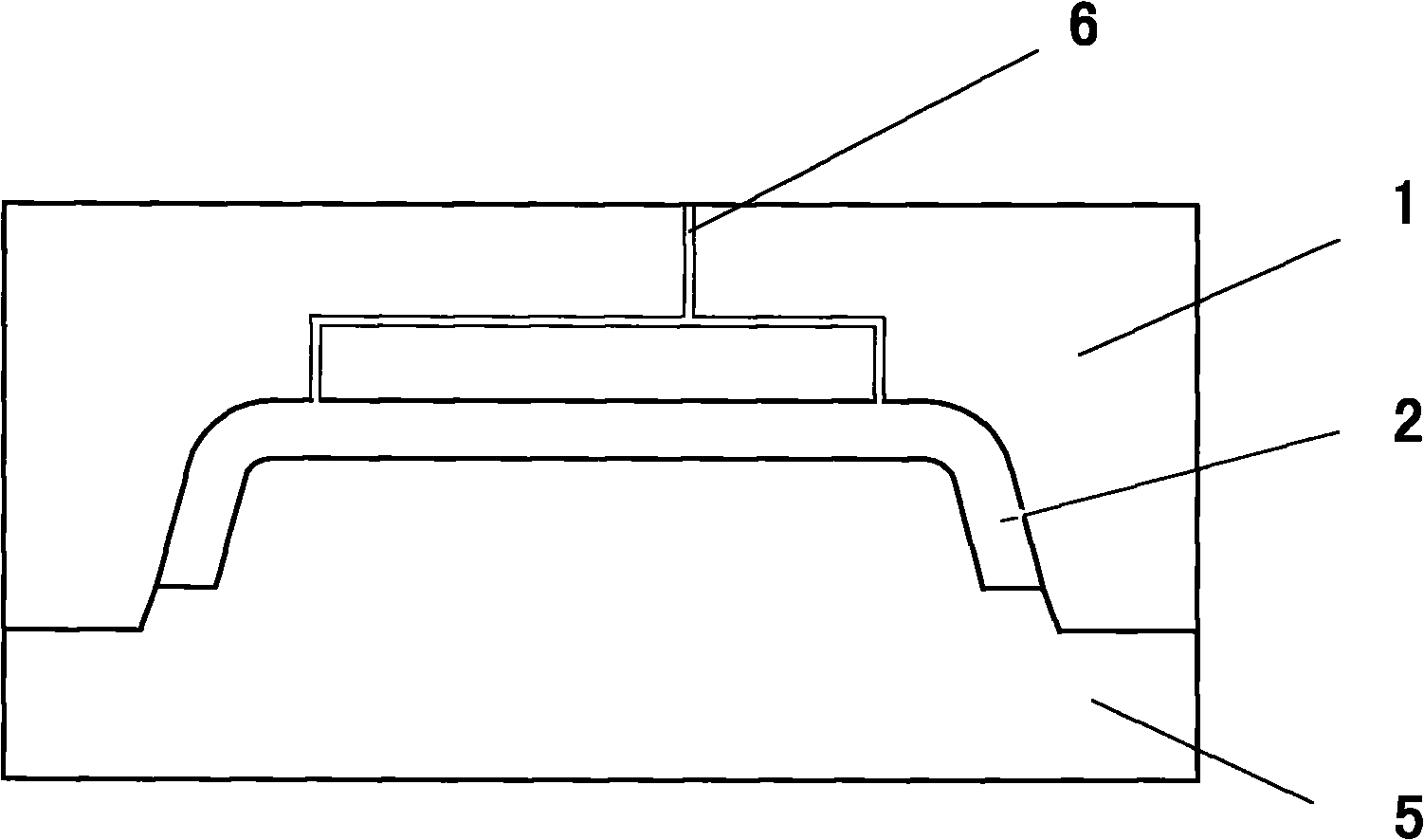

[0036] ④ Die-cut the film; directly die-cut the film to a size consistent with the size of the panel; for a panel with a curved surface, the film is also formed into a curved shape that is basically consistent with the curved panel during heating and forming; the heating forming mold , the upper mold is a metal mold, the lower mold for placing the fil...

Embodiment 2

[0041] The difference between this embodiment and Example 1 is that it adopts the way of horn diving into the glue, the plastic pouring channel is horn-shaped 401, and the thimble is 77. When the mold is released, the thimble 77 will cool the horn-shaped plastic material head 402 Eject forward, because horn becomes lever shape in mold, easily comes off with composite panel 22. In this way, processing efficiency is improved.

[0042] Since the injection molding temperature is as high as 200°C-300°C, the temperature resistance of the ink is required to be high. Conventional inks are prone to ink flushing, discoloration, and delamination after being subjected to high-temperature injection molding. We choose different inks to make a combination, reduce the cyclohexanone and ethylene glycol components, replace them with ester solvents, and add high temperature resistant additives to the inks to cure the ink layer to meet the high temperature impact of injection molding, greatly imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com