Turbine cooling cascade with vortex structure

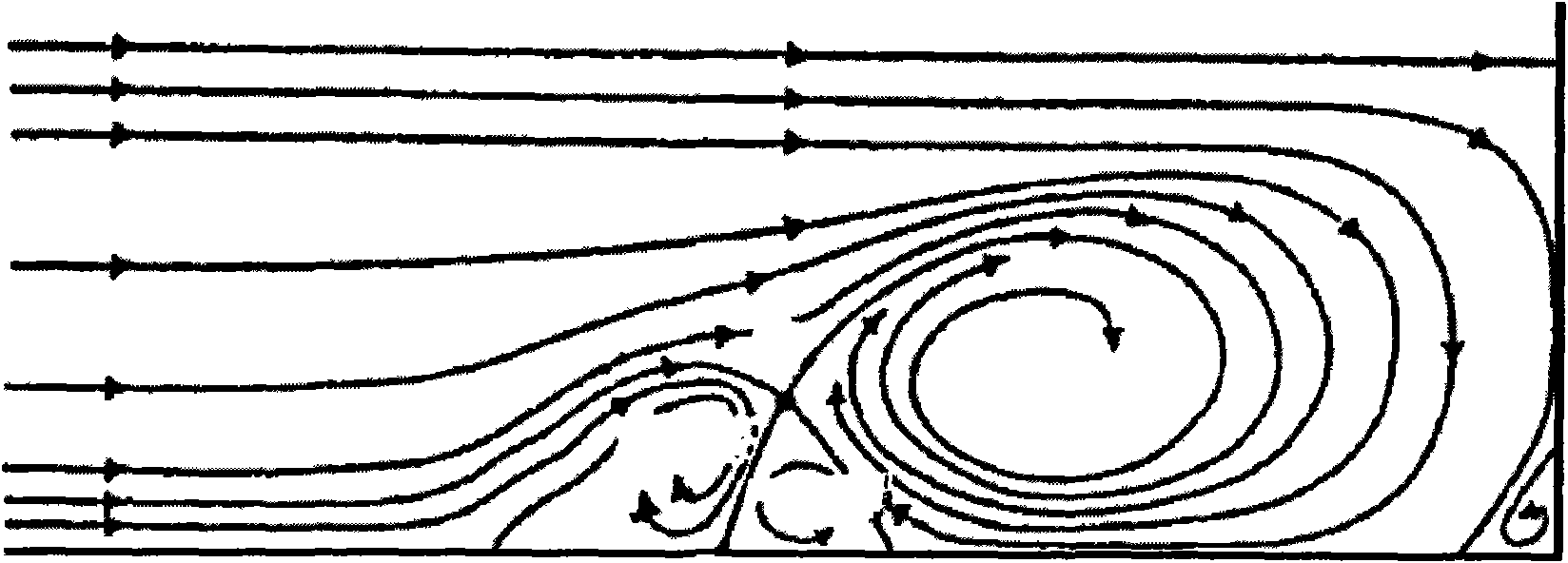

A turbine cooling and trapped vortex technology, applied in the combustion method, combustion chamber, combustion equipment, etc., can solve the problems of easy burnout of the leading edge end wall of the blade, affecting the performance of the blade cascade, and significant heat transfer characteristics, reducing cold air. The effect of utilization, reduction of mixing loss, and improvement of air-conditioning utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

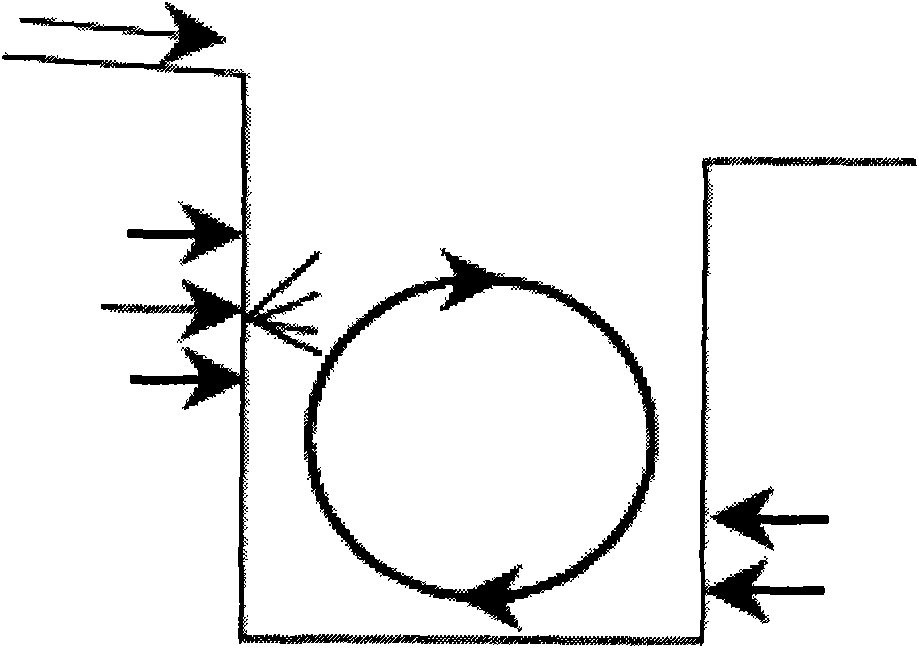

[0009] Embodiment 1: Combining Figure 4 ~ Figure 7 Describing this embodiment, the turbine cooling cascade with trapped vortex structure of this embodiment includes a wall 1 and a blade 2, the blade 2 is arranged on the wall 1, and the blade 2 is close to the pressure surface of the blade leading edge 2-1 2-2, the suction surface 2-3 of the blade 2 close to the leading edge of the blade 2-1, and the end wall 1-1 of the blade leading edge of the wall 1 are provided with a plurality of long grooves 3 arranged in rows, and the blade 2 Each long groove 3 on the pressure surface 2-2 close to the blade leading edge 2-1 and each long groove 3 on the suction surface 2-3 of the blade 2 close to the blade leading edge 2-1 are along the height direction of the blade 2 Open, each long groove 3 on the blade leading edge end wall 1-1 of the wall 1 is opened along the width direction of the wall 1, and one side wall of each long groove 3 is opened along the length direction of the long groo...

specific Embodiment approach 2

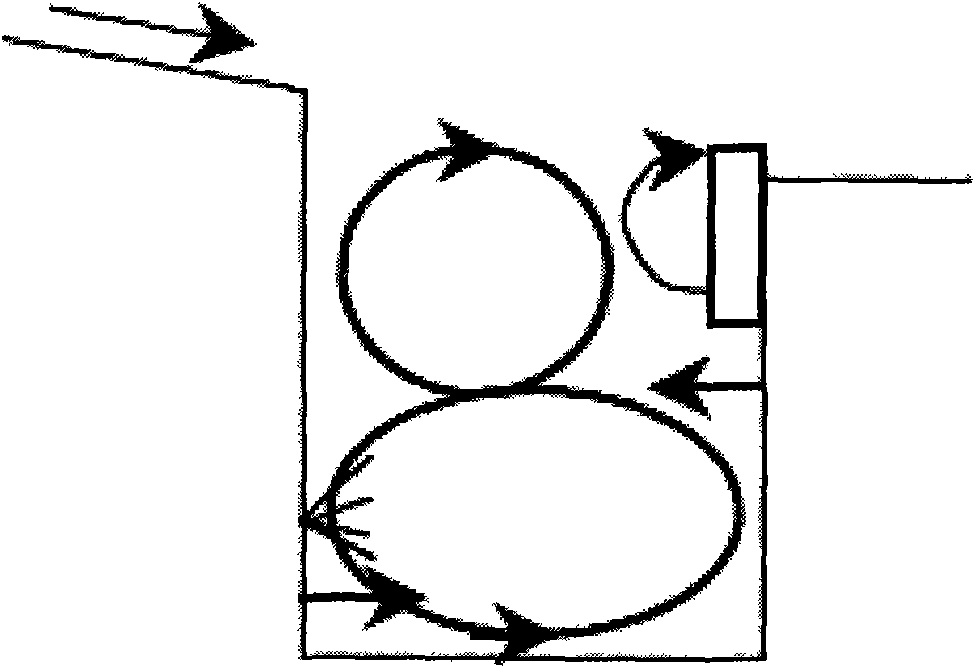

[0010] Specific implementation mode 2: Combining Figure 4 ~ Figure 7 Illustrating this embodiment, in this embodiment, the pressure surface 2-2 of the blade 2 close to the trailing edge 2-4 of the blade and the suction surface 2-3 of the blade 2 close to the trailing edge 2-4 of the blade are both opened in rows. Each long groove 3 on the pressure surface 2-2 of the blade 2 close to the trailing edge 2-4 of the blade and each long groove 3 on the suction surface 2-3 of the blade 2 close to the trailing edge 2-4 of the blade All are opened along the height direction of the blade 2 . This arrangement effectively avoids the burnout of the pressure surface, the suction surface and the high temperature area of the trailing edge, and effectively improves the overall performance of the blade. Other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation three: combination Figure 4 ~ Figure 7 Illustrating this embodiment, the cross section of the long groove 3 in this embodiment is a square, a trapezoid or a semicircle. In this way, the blade as a whole has diversity, and the strength of the standing vortex and the covering effect of the thin-layered gas film are better. Other compositions and connection relationships are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com