Silicon of insulator and its making technology

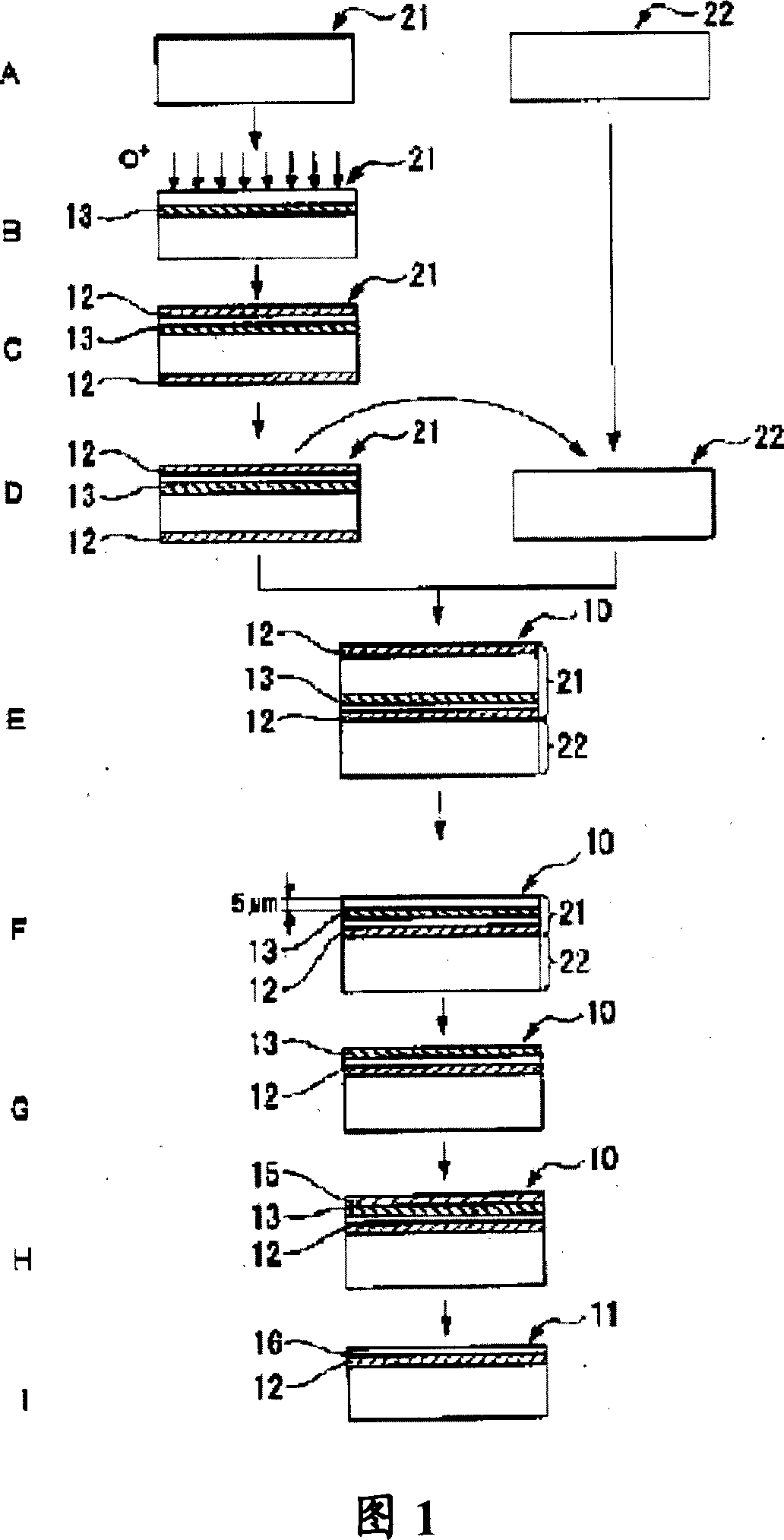

A silicon-on-insulator and preparation technology, which is applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problems of small thickness of top silicon, small thickness of buried insulating layer, poor adjustability, etc., and achieve improvement Performance, reduction of direct impact, and effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

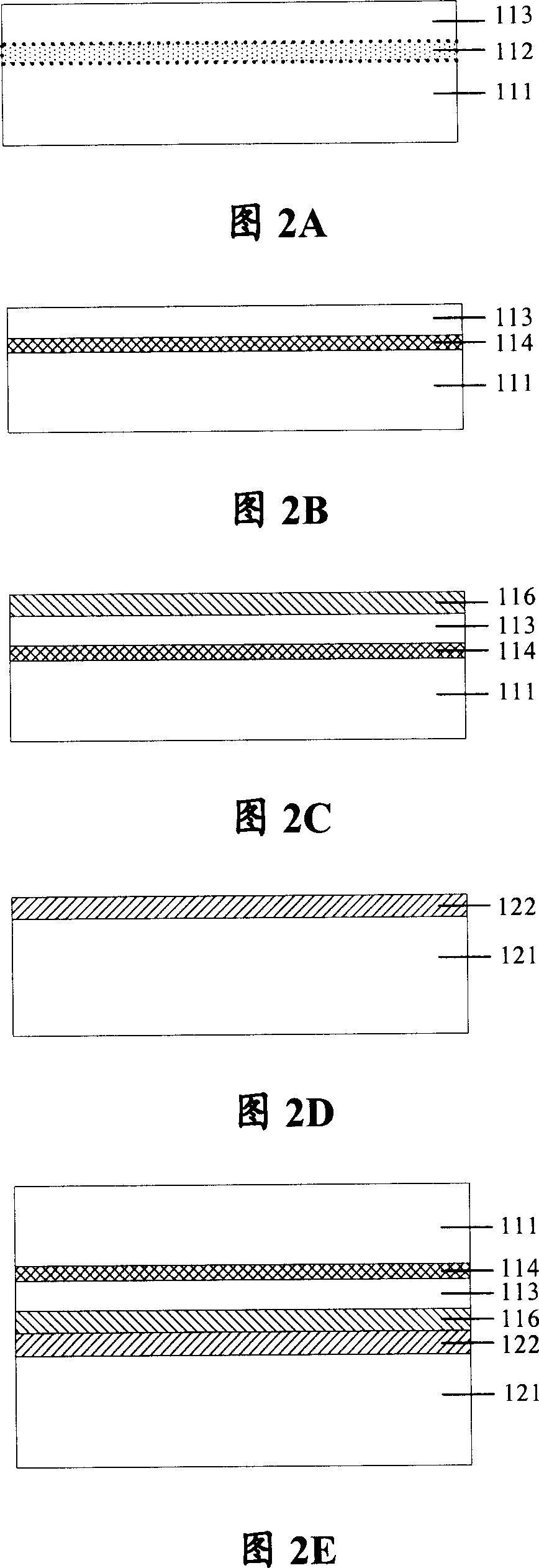

[0079] In this embodiment, the surface silicon layer is the first surface silicon layer 113 shown in FIGS. 2A to 2I , and the insulating layer is the first insulating layer 116 .

[0080] Referring to FIG. 2A, it is a schematic diagram of the cross-sectional structure of the silicon wafer after implanting ions capable of reacting with silicon to form an etching barrier material on the silicon wafer. As shown in the figure, after the ion implantation, an ion implantation layer 112 is formed in the silicon wafer. The ion implantation layer 112 divides the silicon wafer into a first surface silicon layer 113 and a substrate silicon layer 111 . The ions implanted on the silicon wafer that can react with silicon to form corrosion barrier materials are nitrogen ions or oxygen ions, or other ions such as carbon ions. Generally speaking, the basic principle for selecting implanted ions is the ions formed after ion implantation The implanted layer 112 can be used as a barrier layer for...

Embodiment 2

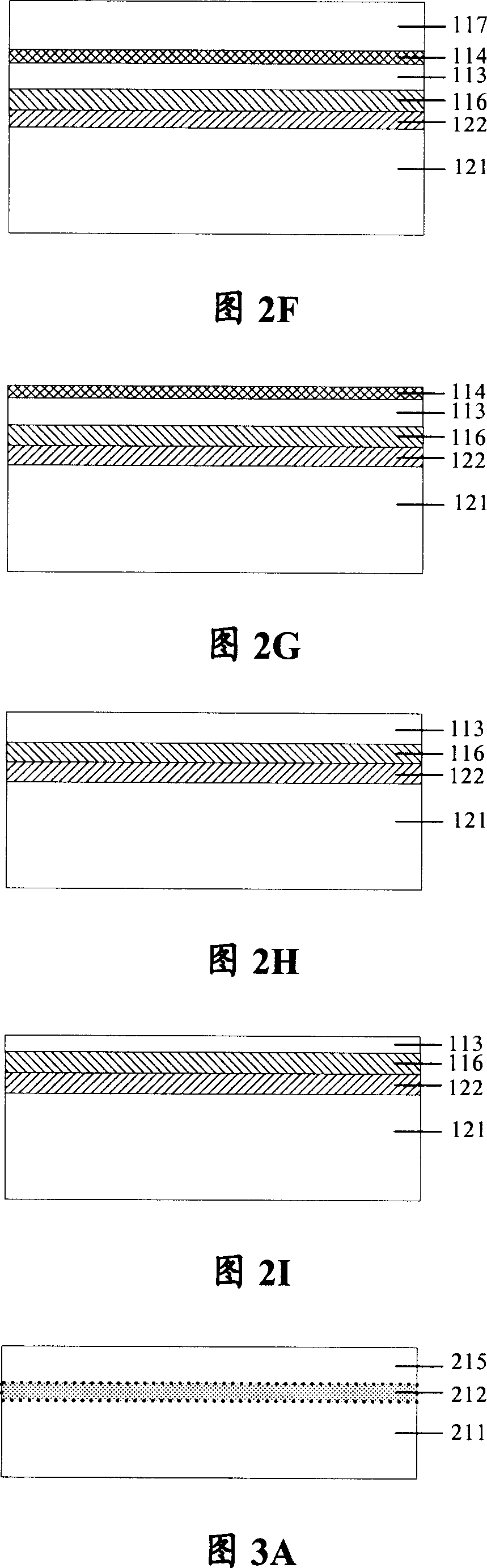

[0136] In this embodiment, the surface silicon layer is the sum of the first surface silicon layer 215 and the second surface silicon layer 217 shown in FIGS. 3A to 3J , and the insulating layer is the third insulating layer 218 .

[0137] Referring to FIG. 3A, it is a schematic diagram of the cross-sectional structure of the silicon wafer after implanting ions capable of reacting with silicon to form a corrosion barrier material on the silicon wafer. As shown in the figure, after the ion implantation, an ion implantation layer 212 is formed in the silicon wafer. The ion implantation layer 212 divides the silicon wafer into a first surface silicon layer 215 and a substrate silicon layer 211 . The ions implanted on the silicon wafer that can react with silicon to form corrosion barrier materials are nitrogen ions or oxygen ions, or other ions such as carbon ions. Generally speaking, the basic principle for selecting implanted ions is the ions formed after ion implantation The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com