One-kiln multi-line float glass production method and device

A float glass and production method technology, which is applied in the field of float glass production, can solve the problems of excessive glass liquid, lower yield, large melting volume, etc., and achieve the effects of reducing the amount of glass liquid, reducing production costs, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

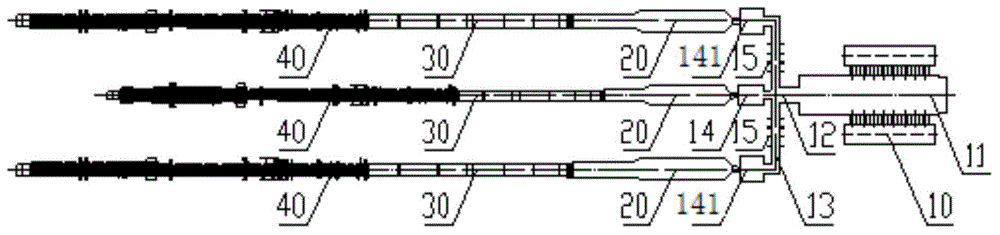

[0022] Example 1. One kiln multi-line float glass production device, the composition is as follows figure 1 As shown, it includes a large-tonnage melting furnace 10, the melting portion 11 of the large-tonnage melting furnace 10 is connected with a neck 12, and the neck 12 is connected with the main cooling portion 14 and two large passages 13 respectively; the neck 12 The cross-sectional area is enlarged (compared with the neck cross-sectional area of the same conventional float glass production line), and the amplification factor is 1.05-1.25, which is equivalent to 1.05-1.25 times of the conventional neck width; the main cooling part 14 and branch The area of the cooling section 141 is reduced (compared with that of the same conventional float glass production line), and the reduction factor is 0.6-0.95. The two sides of the large passage 13 are respectively provided with temperature and pressure regulators 15 . Both the ultra-thin glass production line and the float ...

Embodiment 2

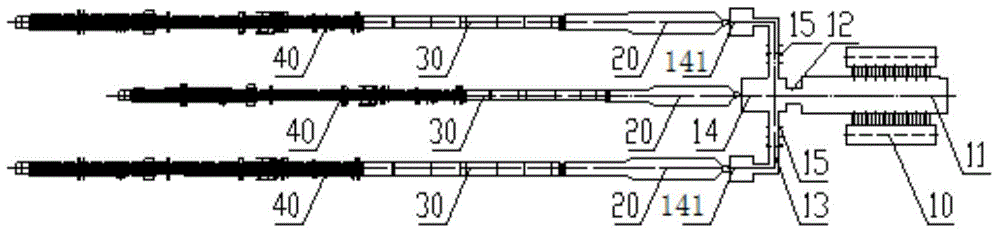

[0023] Example 2. One kiln multi-line float glass production device, the composition is as follows figure 2 As shown, it includes a large-tonnage melting furnace 10 , the melting part 11 of the large-tonnage melting furnace 10 is connected with clamping necks 12 , the clamping necks 12 are respectively connected with the main cooling part 14 , and the main cooling part 14 is connected with two large passages 13 . The two sides of the large passage 13 are respectively provided with temperature and pressure regulators 15 . Both the ultra-thin glass production line and the float glass production line include a float bath 20 for a forming section, a float annealing kiln 30 for an annealing section, and a float cold end 40 . The float process tin bath 20, the float process annealing kiln 30, and the float process cold end 40 may be the same or different.

Embodiment 3

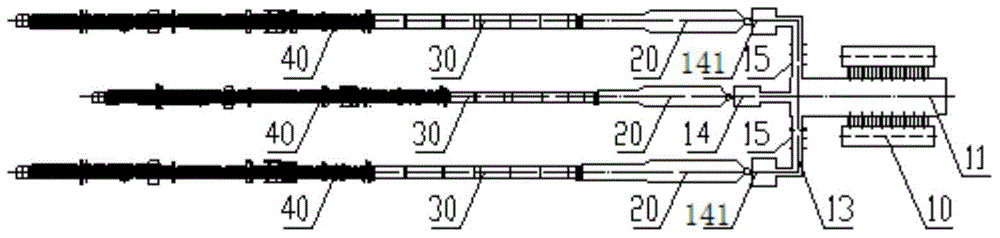

[0024] Example 3. One kiln multi-line float glass production device, the composition is as follows image 3 As shown, a large tonnage melting furnace 10 is included, and the melting part 11 of the large tonnage melting furnace 10 is connected to the main cooling part 14 and two large passages 13 respectively. The two sides of the large passage 13 are respectively provided with temperature and pressure regulators 15 . Both the ultra-thin glass production line and the float glass production line include a float bath 20 for a forming section, a float annealing kiln 30 for an annealing section, and a float cold end 40 . The float process tin bath 20, the float process annealing kiln 30, and the float process cold end 40 may be the same or different.

[0025] The large-tonnage melting furnace 10 described in Embodiments 1, 2 and 3 is a melting furnace of more than 500 T / D.

[0026] Compared with one kiln and one line, the present invention reduces the direct impact on the coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com