Fusing method of laser welding with filler wires using double TIG welding torches

A technology of laser wire filling and welding torch, which is applied in the direction of laser welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of large deformation of welding joints, high precision requirements in welding wire, and poor mechanical properties of welds, so as to reduce heat loss. Effect of input, reduction of weld porosity, and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

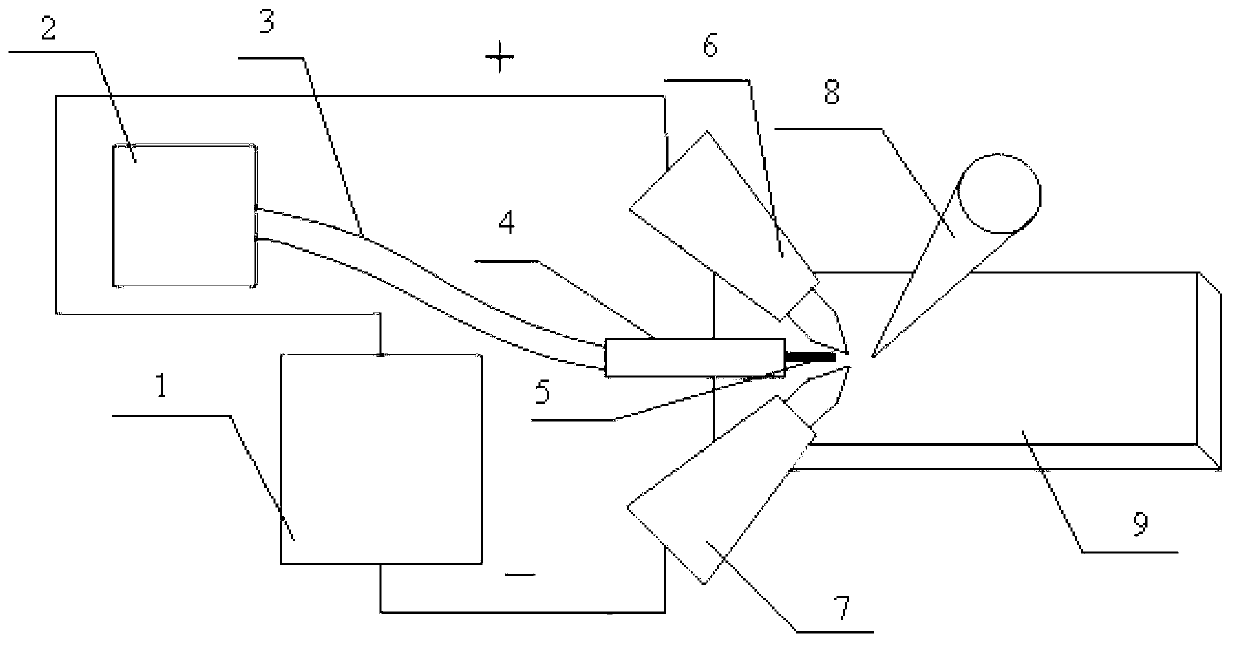

[0024] Specific embodiment one: a kind of fuse method that adopts the laser filler wire welding of double TIG welding torch in the present embodiment is carried out according to the following steps:

[0025] 1. When the base material is magnesium, aluminum and its alloys, connect two TIG welding guns to the positive and negative poles of the TIG power supply respectively, and connect the negative pole of the TIG power supply to the base metal, and the TIG power supply adopts a DC output form;

[0026] 2. Start the laser to make the laser form a molten pool on the base material. The output type of the laser adopts continuous output or pulse output, and the laser power is 500W~5000W;

[0027] 3. Turn on the shielding gas so that the shielding gas is ejected from the coaxial wire feeding gas nozzle, and then connect the TIG power supply to start the arc between the two TIG welding torches, start the wire feeding system so that the welding wire is continuously sent out, and adjust ...

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the output current of the TIG power supply in Step 1 is 10A~120A. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

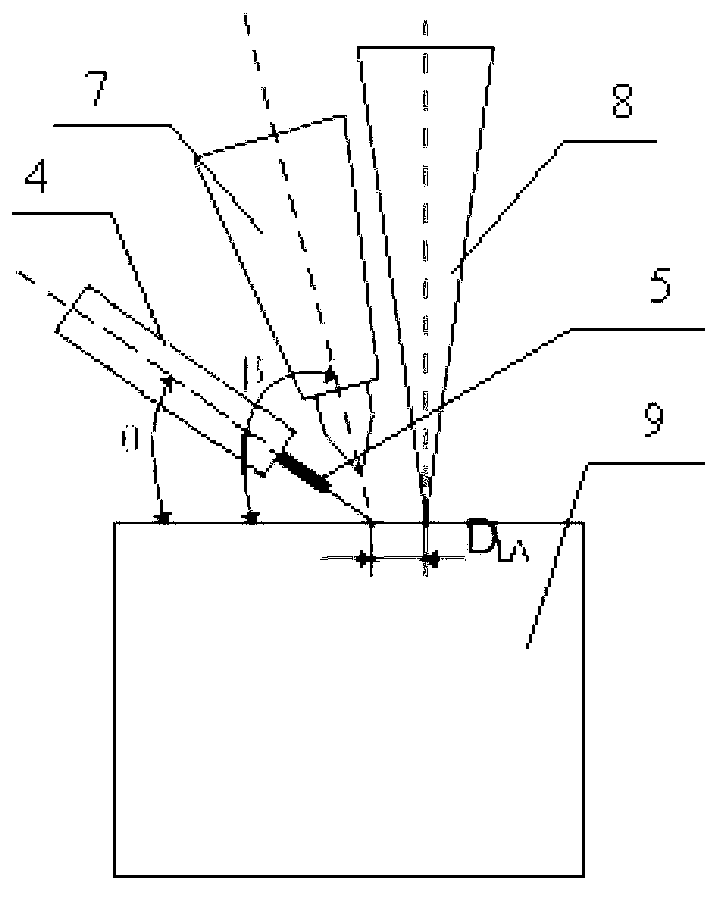

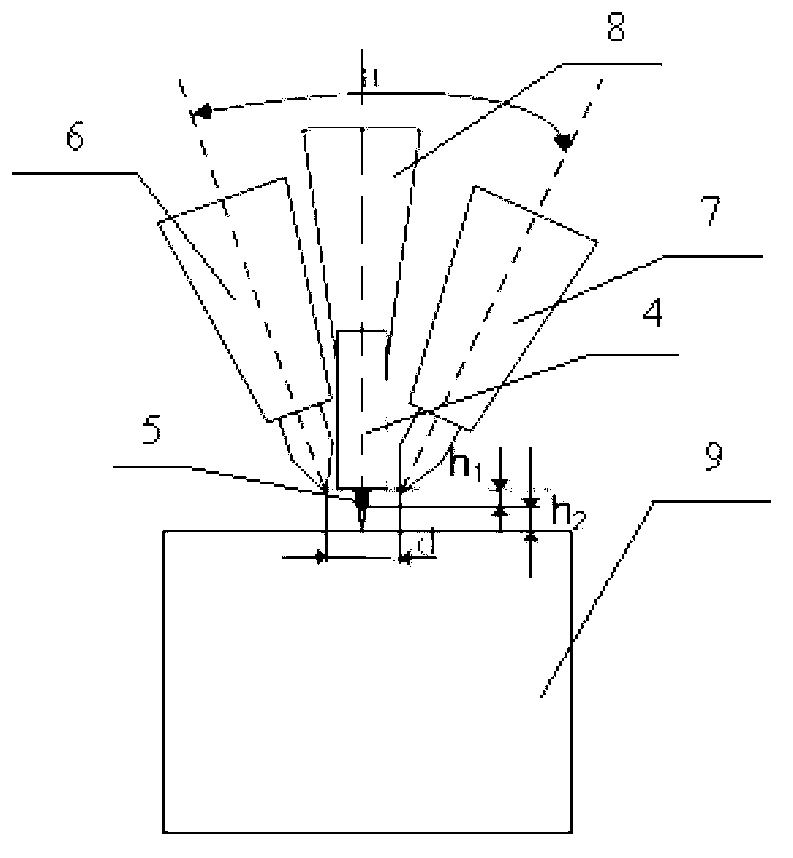

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the horizontal distance between the two TIG welding torches in step one is 0 mm ~ 8 mm, and the angle α between the two TIG welding torches is 10 ° ~ 160 °, The angle β between the plane where the two TIG welding torches are located and the base metal is 30°-90°. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com