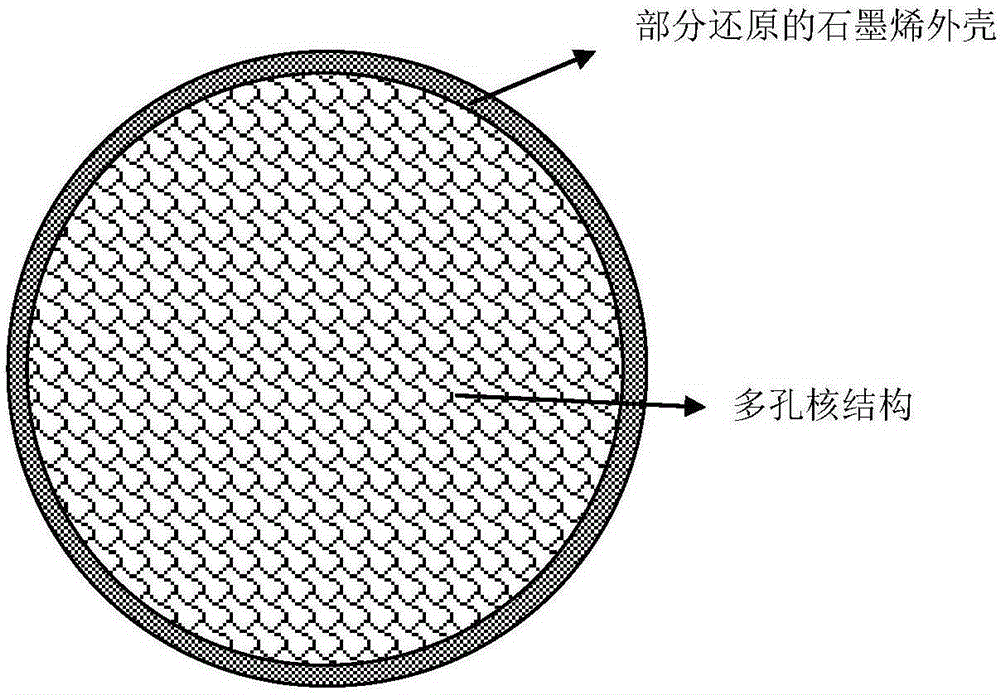

Graphene clad porous granular material and preparation method thereof

A graphene coating, graphene technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low chemical vapor deposition production efficiency, difficult to meet cheap large-scale preparation, poor lithium ion penetration ability, etc. Achieve the effect of avoiding direct contact with silicon, reducing formation, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of silicon-containing alloys

[0044] Put silicon and aluminum into a resistance furnace with a mass ratio of 20:80, heat it to 800°C to melt, and keep it warm for 30 minutes. After the alloy composition is uniform, it is poured into an alloy ingot.

[0045] (2) Preparation of alloy powder

[0046] Put the alloy ingot obtained in step (1) into the ladle at the upper end of the spray deposition powder making equipment, heat it to 800°C to melt and keep it warm for 30 minutes, then open the ladle, and use high-purity nitrogen as the cooling medium in the high-speed atomization equipment Al-Si alloy balls with a diameter of 50 microns were prepared.

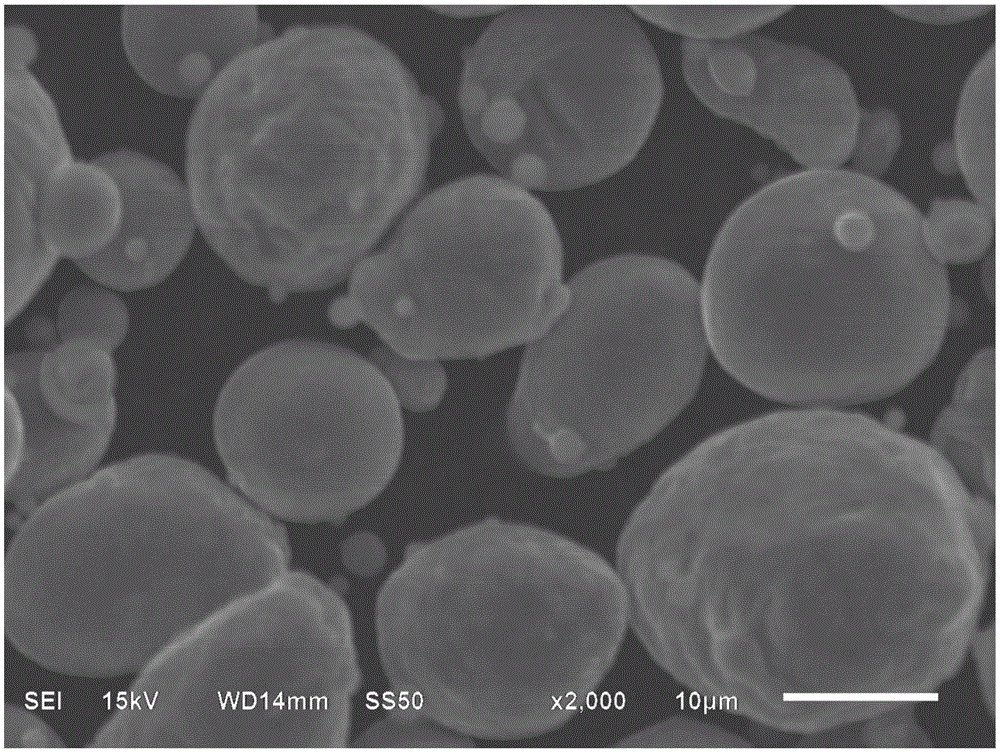

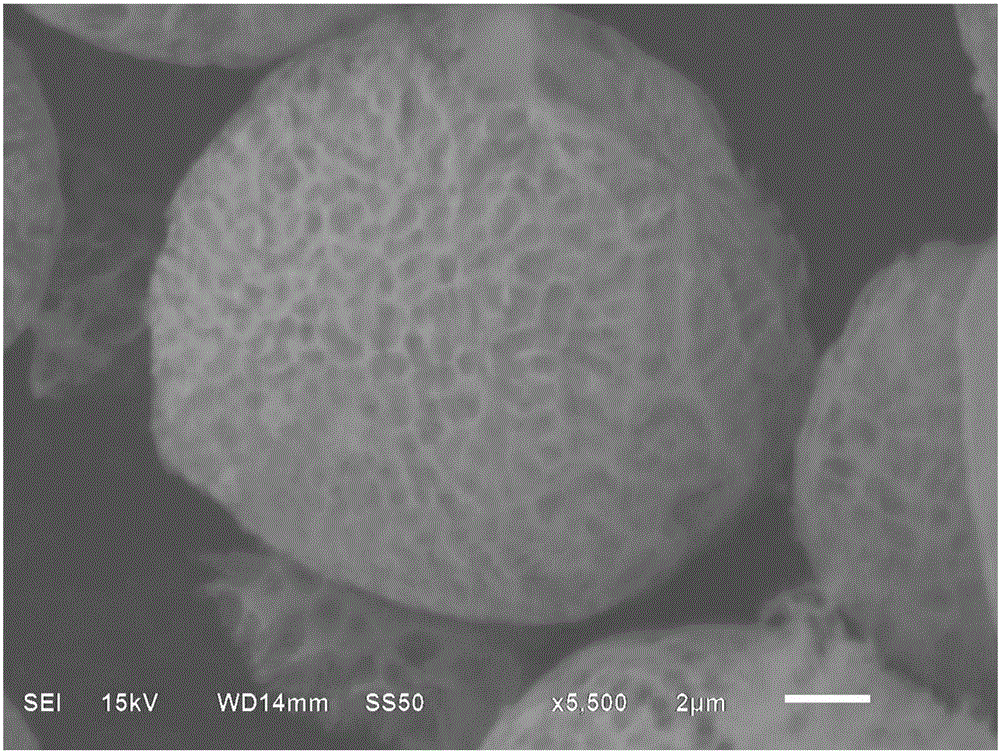

[0047] (3) Preparation of graphene-coated porous silicon composites

[0048] Put the silicon alloy balls obtained in step (2) into the graphene oxide aqueous solution with a concentration of 2 mg / mL, and after stirring by magnetic force for 24 hours, add sulfuric acid with a concentration of 1 mole per liter...

Embodiment 2

[0050] (1) Preparation of silicon-containing alloys

[0051] Put silicon and zinc metal into a resistance furnace with a mass ratio of 10:90, heat to 600°C to melt, and keep it warm for 30 minutes. After the alloy composition is uniform, it is poured into an alloy ingot.

[0052] (2) Preparation of alloy powder

[0053] Put the alloy ingot obtained in step (1) into the ladle at the upper end of the spray deposition powder making equipment, heat it to 600°C to melt and keep it warm for 30 minutes, then open the ladle, and use high-purity nitrogen as the cooling medium in the high-speed atomization equipment Al-Si alloy balls with a diameter of 20 microns were prepared.

[0054] (3) Preparation of graphene / silicon composite materials

[0055] Put the silicon alloy balls obtained in step (2) into an aqueous solution of graphene oxide with a concentration of 5 mg / mL, stir magnetically for 24 hours, add sulfuric acid with a concentration of 2 moles per liter, react for 24 hours, ...

Embodiment 3

[0057] The rate discharge performance test of graphene-coated porous silicon was carried out according to routine tests. The result is as Figure 7 shown. The performance of the graphene-coated porous silicon material did not change after 20 cycles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com