Method for preparing modified micro particles coated with graphene oxide

A graphene-coated, particle-based technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of reduced cement strength, large specific surface area, and increased water demand, to improve performance and operation Simple, even distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Add 1g of fly ash into 500ml of absolute ethanol and sonicate for 60min. Add 0.08 g of a silane coupling agent (3-aminopropyltrimethoxysilane), and heat and stir at 80° C. for 12 h. Cool to room temperature after the reaction, centrifuge the obtained suspension with a centrifuge, remove the obtained supernatant, redissolve the centrifuged solid in absolute ethanol, and centrifuge again, repeating 3-5 times. Then, the above steps are repeated using deionized water to remove the residual coupling agent to obtain the fly ash modified by the coupling agent.

[0030] (2) Add 2g of graphite oxide into 500ml of deionized water, stir for 60-120min, and sonicate for 1-2h to prepare a 4mg / ml graphene oxide solution.

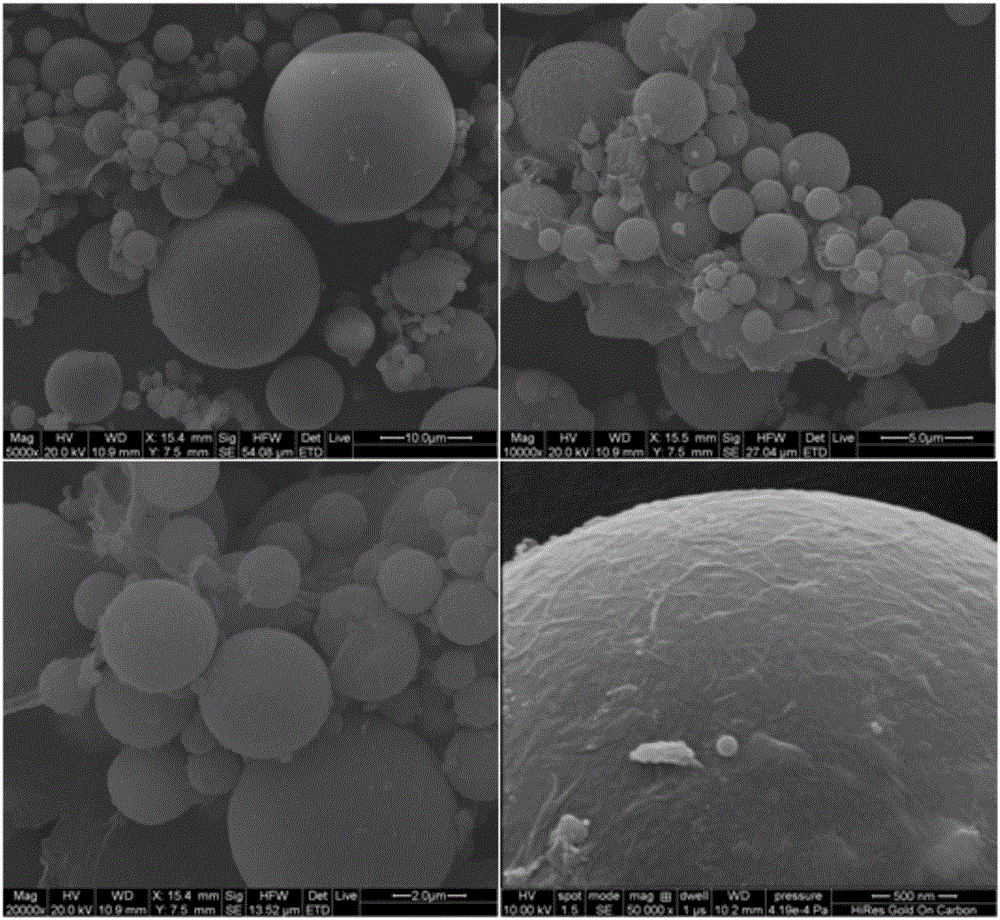

[0031] (3) 10ml of graphene oxide solution was added dropwise to the fly ash modified by the coupling agent. With the addition of graphene oxide, the modified fly ash and graphene oxide co-settled to the bottom of the solution due to electrostatic interaction. ...

Embodiment 2

[0034] (1) Add 0.5g of mineral powder into 500ml of absolute ethanol and sonicate for 60min. Add 0.01 g of a silane coupling agent (3-aminopropyltrimethoxysilane), and heat and stir at 80° C. for 12 h. Cool to room temperature after the reaction, centrifuge the obtained suspension with a centrifuge, remove the obtained supernatant, redissolve the centrifuged solid in absolute ethanol, and centrifuge again, repeating 3-5 times. Then repeat the above steps with deionized water to remove the residual coupling agent to obtain the mineral powder modified by the coupling agent.

[0035] (2) Add 2g of graphite oxide into 500ml of deionized water, stir for 60-120min, and sonicate for 1-2h to prepare a 4mg / ml graphene oxide solution.

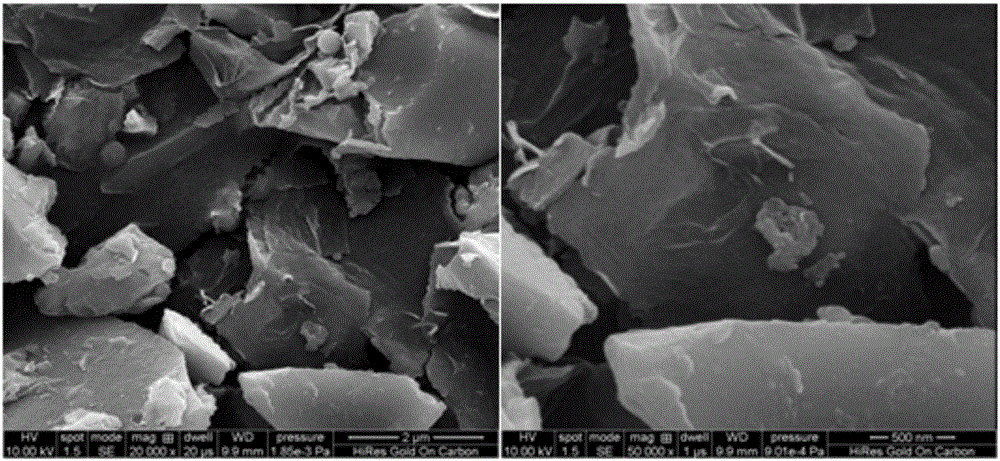

[0036] (3) 5ml of graphene oxide solution was added dropwise to the mineral powder modified by the coupling agent. With the addition of graphene oxide, the modified mineral powder and graphene oxide co-settled to the bottom of the solution due to electr...

Embodiment 3

[0039] (1) Add 0.1 g of aluminum powder into 0.01 g of silane coupling agent (3-aminopropyltrimethoxysilane), and heat and stir at 80° C. for 12 h. After the reaction, cool down to room temperature, take out the silane coupling agent and wash it repeatedly with deionized water to remove the remaining coupling agent to obtain aluminum powder modified by the coupling agent.

[0040] (2) Add 2g of graphite oxide into 500ml of deionized water, stir for 60-120min, and sonicate for 1-2h to prepare a 4mg / ml graphene oxide solution.

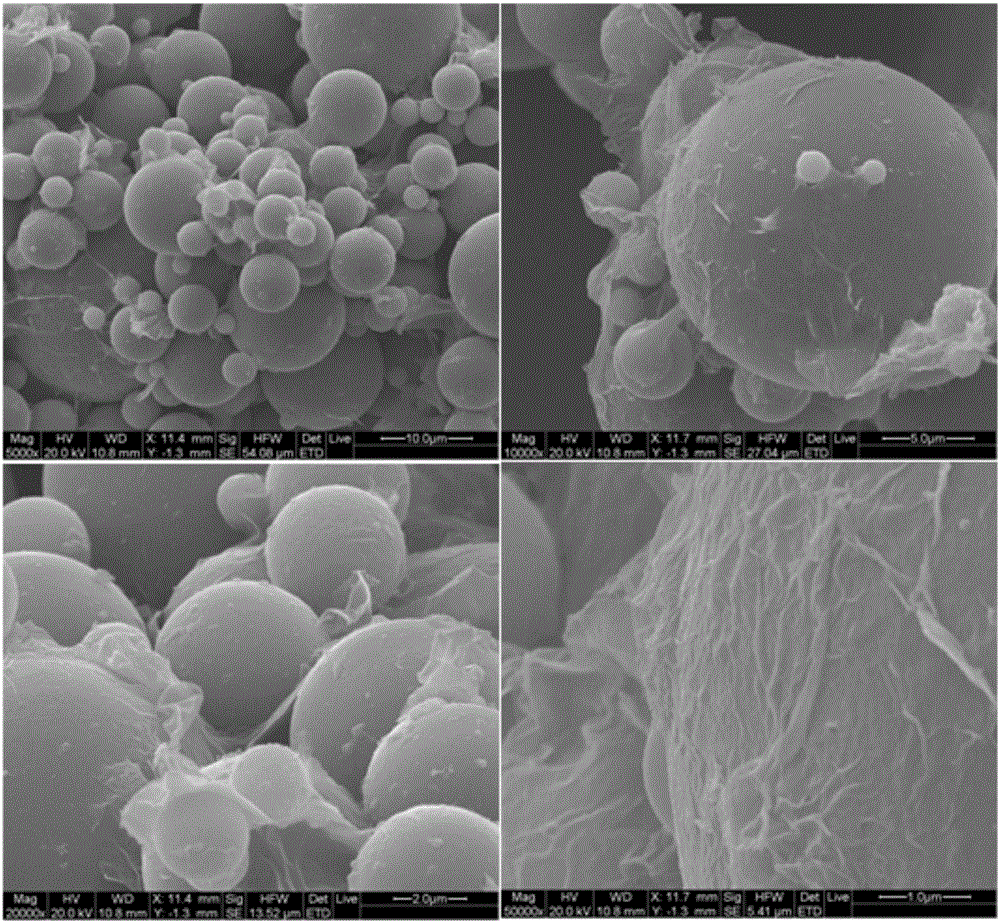

[0041] (3) 5ml of graphene oxide solution was added dropwise to the coupling agent modified aluminum powder, and with the addition of graphene oxide, the modified aluminum powder and graphene oxide co-settled to the bottom of the solution due to electrostatic interaction. The upper layer solution was removed, and the lower layer solid was vacuum-dried at 45-60° C. for 24 hours to obtain graphene oxide-modified aluminum powder.

[0042] The field emissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com