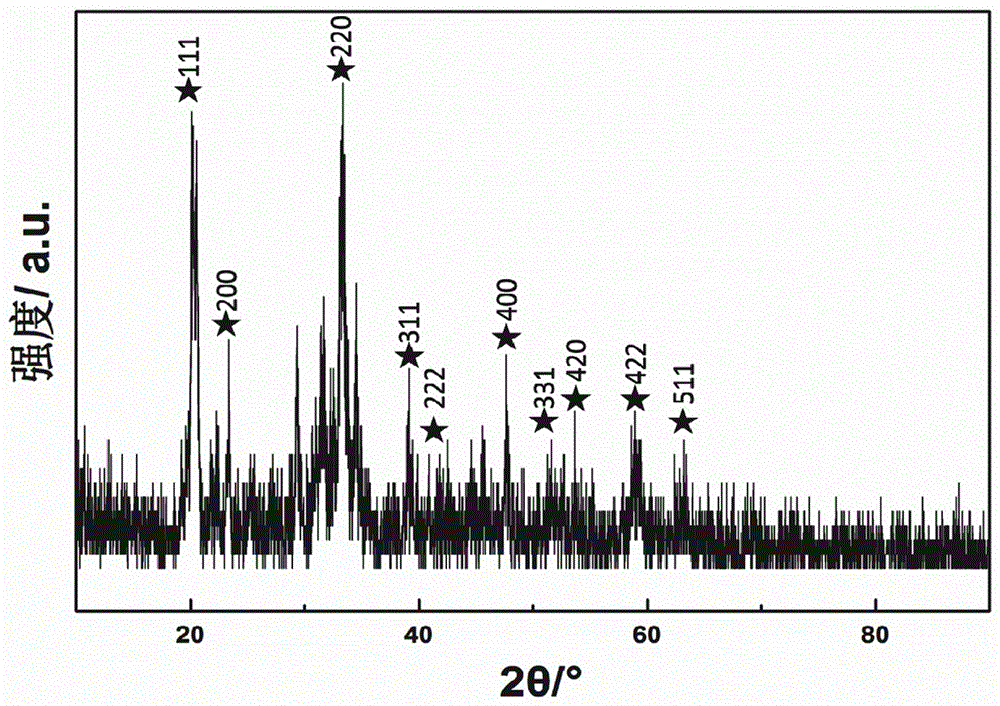

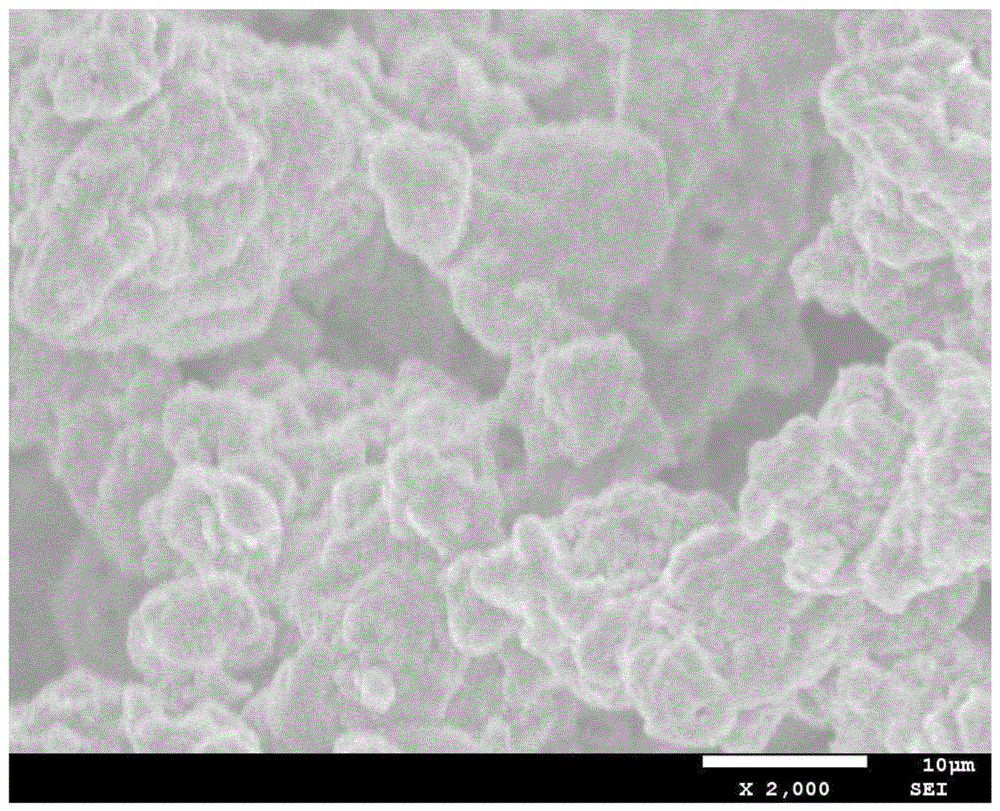

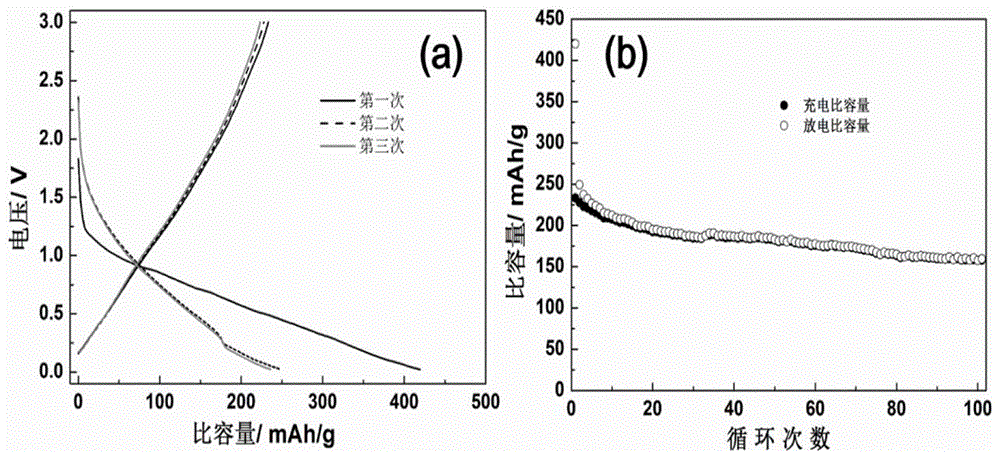

Carbon coated Na3VO4 composite anode material and preparation method and application thereof

A negative electrode material and carbon coating technology, applied in the field of electrochemical power supply, can solve the problems of unsatisfactory electrochemical performance and poor conductivity, and achieve the effects of good cycle performance, good uniformity and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The material synthesis steps are as follows:

[0021] 1) Weigh 3mmol and 2mmol of sodium carbonate and ammonium metavanidate according to the molar ratio of 3:2, respectively, and dissolve them in beakers A and B with 10ml of distilled water, and stir on a magnetic stirrer for 40min to fully dissolve;

[0022] 2) Weigh 5mmol hexamethylenetetramine and dissolve it in the C beaker with 10ml distilled water, transfer the solution in the B and C beakers in step 1) to the A beaker, stir on a magnetic stirrer for 40min to obtain a uniform color solution;

[0023] 3) Transfer the homogeneously colored solution obtained in steps 1) and 2) to the lining of a 50ml hydrothermal kettle, add distilled water to 80% of its volume, react in a blast oven at 120°C for 24h, and then heat it at 180°C React in an air oven for 24 to 72 hours, then cool naturally to room temperature;

[0024] 4) adding citric acid with a theoretical carbon content of 10% to the product obtained in step 3); ...

Embodiment 2

[0028] The material synthesis steps are as follows:

[0029] 1) Weigh 6 mmol and 2 mmol of sodium acetate and ammonium metavanadate according to the molar ratio of 3:1 and dissolve them in beakers A and B filled with 10 ml of distilled water, and stir on a magnetic stirrer for 20 minutes to fully dissolve;

[0030] 2) Weigh 5mmol hexamethylenetetramine and dissolve it in the C beaker with 10ml distilled water, transfer the solution in the A and B beakers in step 1) to the C beaker, stir on a magnetic stirrer for 40min to obtain a uniform color solution;

[0031] 3) Transfer the homogeneously colored solution obtained in steps 1) and 2) to the lining of a 50ml hydrothermal kettle, and add distilled water to 80% of its volume, react in a blast oven at 120°C for 24h, and then heat it in a 180°C React in a blast oven for 24 to 72 hours, then cool to room temperature naturally;

[0032] 4) adding glucose with a theoretical carbon content of 10% to the product obtained in step 3);...

Embodiment 3

[0036] The material synthesis steps are as follows:

[0037] 1) Weigh 6 mmol and 1 mmol of sodium acetate and ammonium vanadium pentoxide according to the molar ratio of 6:1, respectively, and dissolve them in beakers A and B filled with 10 ml of distilled water, and stir on a magnetic stirrer for 20 minutes to fully dissolve;

[0038] 2) Weigh 5mmol hexamethylenetetramine and dissolve it in the C beaker with 10ml distilled water, transfer the solution in the A and B beakers in step 1) to the C beaker, stir on a magnetic stirrer for 40min to obtain a uniform color solution;

[0039] 3) Transfer the homogeneously colored solution obtained in steps 1) and 2) to the lining of a 50ml hydrothermal kettle, and add distilled water to 80% of its volume, react in a blast oven at 120°C for 24h, and then heat it in a 180°C React in a blast oven for 24 to 72 hours, then cool to room temperature naturally;

[0040] 4) adding sucrose with a theoretical carbon content of 10% to the product...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com