Method for preparing supercapacitor electrode material through cobalt-nickel bimetallic oxide and graphene

A double metal oxide and supercapacitor technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of toxicity, influence on the electrochemical performance of materials, expensive organic solvents, etc., and achieve broad application prospects, Good for electrochemical performance and good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

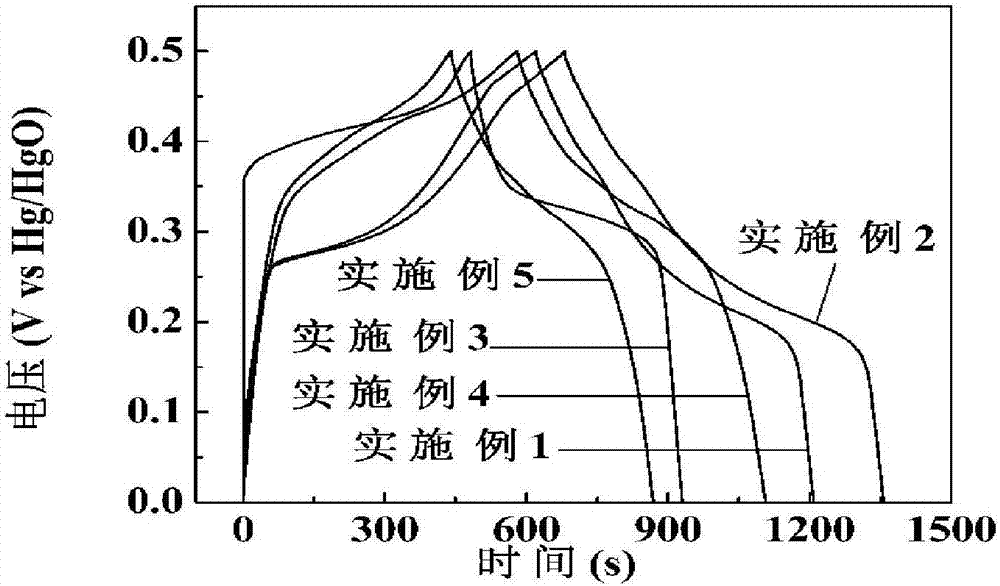

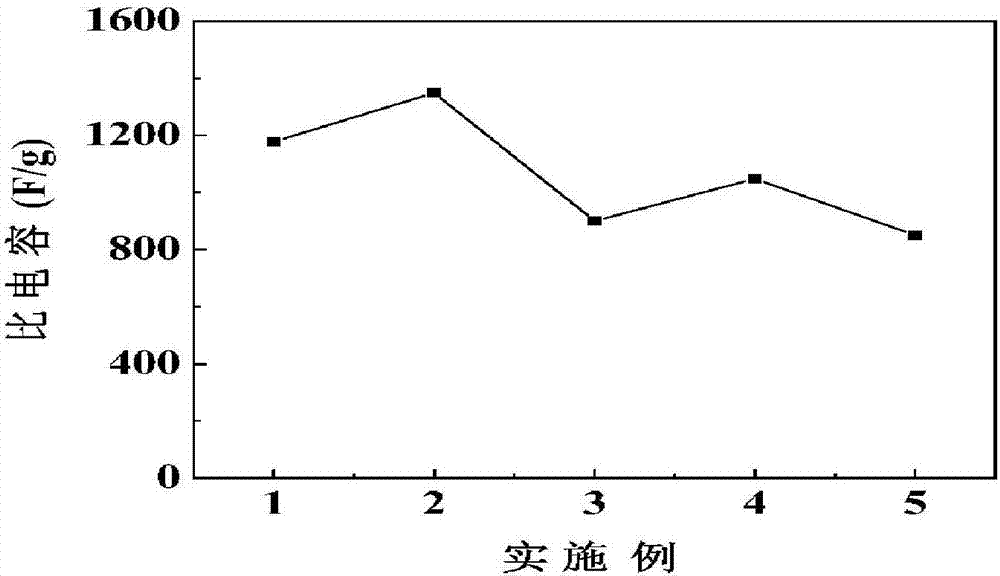

Examples

Embodiment 1

[0037] (1) Add 6 g Co(NO 3 ) 2 ·6H 2 O with 0.6 g Ni(NO3 ) 2 ·6H 2 O was dissolved in 200 mL of deionized water, and ammonia water was added to react, and the pH of the solution was adjusted to 9, and reacted for 2 hours to obtain a cobalt-nickel double metal hydroxide, which was then filtered and washed until neutral. Add cobalt-nickel double metal hydroxide to 2000 mL deionized water, and ultrasonicate for 3 hours in an ultrasonic cleaner with an ultrasonic power of 500 W to obtain a dispersion of cobalt-nickel double metal hydroxide nanosheets.

[0038] (2) Add 20 mL of the graphene oxide aqueous dispersion with a concentration of 5 mg / mL into the cobalt-nickel bimetal hydroxide nanosheet dispersion with a stirring speed of 1000 r / min, and keep stirring for 1 hour to make the two different. The resulting solution was filtered and dried in a freeze dryer at -50°C for 8 hours to obtain a cobalt-nickel double hydroxide and graphene oxide composite precursor.

[0039] (3) ...

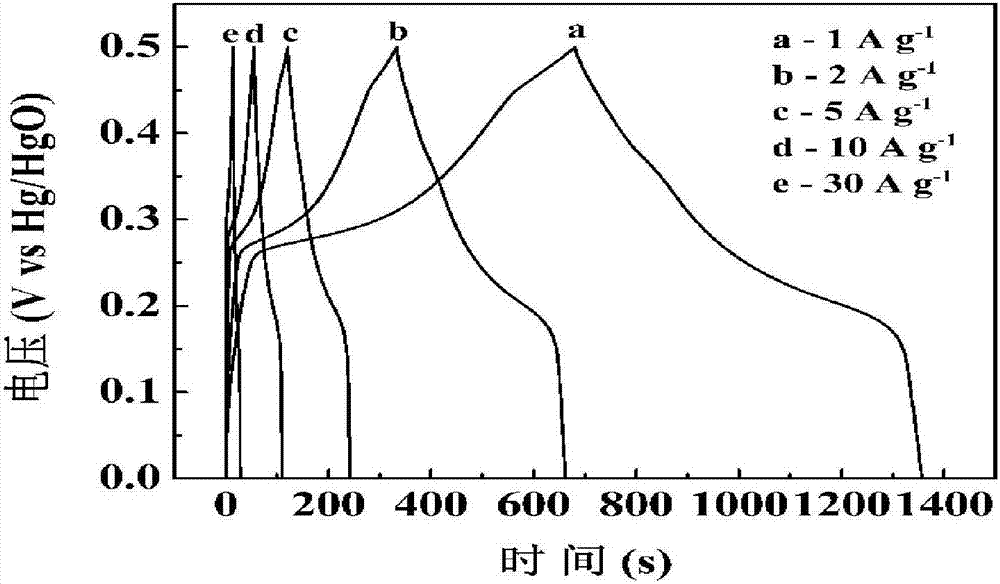

Embodiment 2

[0042] (1) Add 1 g Co(NO 3 ) 2 ·6H 2 O with 0.25 g Ni(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL of deionized water, and ammonia water was added to react, and the pH of the solution was adjusted to 8, and reacted for 2 hours to obtain a cobalt-nickel double metal hydroxide, which was then filtered and washed until neutral. Add cobalt-nickel double metal hydroxide to 2000 mL deionized water, and ultrasonicate for 2 hours in an ultrasonic cleaner with an ultrasonic power of 300 W to obtain a dispersion of cobalt-nickel double metal hydroxide nanosheets.

[0043] (2) Add 10 mL of the graphene oxide aqueous dispersion with a concentration of 2.5 mg / mL into the cobalt-nickel double hydroxide nanosheet dispersion with a stirring speed of 1000 r / min, and keep stirring for 1 hour to make the two The resulting solution was filtered and dried in a freeze dryer at -50°C for 8 hours to obtain a cobalt-nickel double hydroxide and graphene oxide composite precursor.

[0044] (3) The abo...

Embodiment 3

[0047] (1) 1.19 g CoCl 2 ·6H 2 O with 1.19 g NiCl 2 ·6H 2 O was dissolved in 50 mL of deionized water, and ammonia water was added to react, and the pH of the solution was adjusted to 10, and reacted for 1 hour to obtain a cobalt-nickel double metal hydroxide, which was then filtered and washed until neutral. The cobalt-nickel double hydroxide was added into 2000 mL deionized water, and ultrasonicated in an ultrasonic cleaner with an ultrasonic power of 400 W for 1 hour to obtain a dispersion of cobalt-nickel double hydroxide nanosheets.

[0048] (2) Add 15.5 mL of graphene oxide aqueous dispersion with a concentration of 1.5 mg / mL into the cobalt-nickel double hydroxide nanosheet dispersion with a stirring speed of 1000 r / min, and keep stirring for 1 hour to make the two heterogeneous Assemble, filter the resulting solution, and dry in a freeze dryer at -50 °C for 8 hours to obtain a cobalt-nickel double metal hydroxide and graphene oxide composite precursor.

[0049] (3)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com